Chili powder screw conveyor

Friday March-28 2025 18:17:11

What is a chili powder screw conveyor?

Chili powder screw conveyor is a device specially used to convey powdered or small granular materials such as chili powder. It conveys chili powder along the pipe or trough of the conveyor from one place to another through the rotation of the spiral blade. It is suitable for horizontal, inclined or vertical conveying and is widely used in food processing, condiment production and other fields.

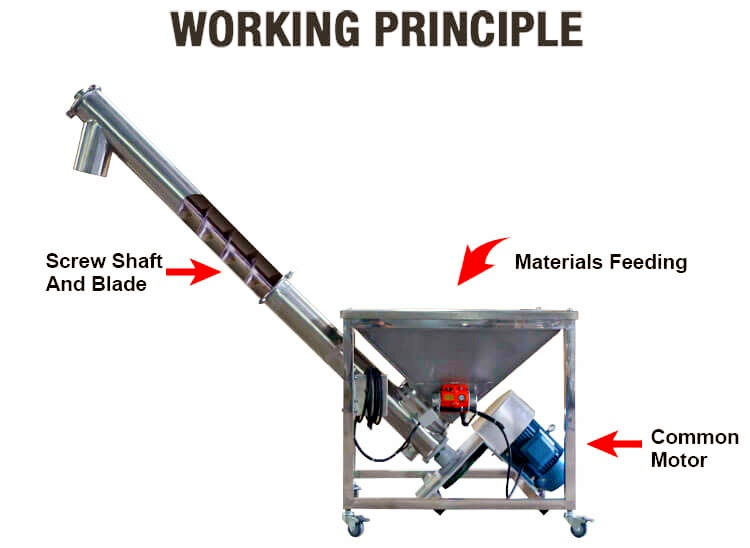

What is the working principle of the chili powder screw conveyor?

①The motor drives the spiral shaft to rotate and the spiral blade starts to operate.

②The chili powder enters the conveying pipe or conveying trough from the feed port and is gradually pushed forward by the spiral blade.

③The centrifugal force and friction force generated when the spiral blade rotates make the chili powder gradually transported upward.

④After being transported to the designated position, it is discharged from the discharge port and can be connected to packaging machines, storage tanks and other equipment.

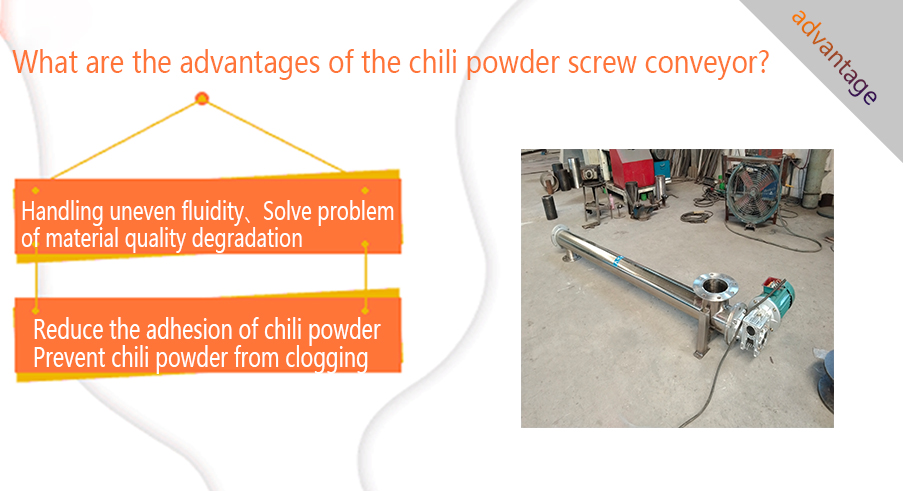

What are the advantages of the chili powder screw conveyor?

Handling uneven fluidity: Chili powder may have inconsistent fluidity due to humidity, particle size or oil content, and sometimes adheres to the inner wall of the pipe. The chili powder screw conveyor adjusts the blade spacing and diameter (such as 100-300mm) to avoid over-crowding or over-sparse accumulation.

Solve the problem of material quality degradation: If the chili powder is overheated or exposed to air during transportation, it may oxidize and discolor, volatilize the aroma, or reduce the quality. The chili powder screw conveyor controls the speed (such as below 100 rpm) to reduce friction heat and prevent the chili powder from overheating.

Reduce the adhesion of chili powder: Reasonably design the gap between the spiral blades of the chili powder screw conveyor and the inner wall of the trough to avoid excessive squeezing of the chili powder and reduce the possibility of adhesion.

Prevent chili powder from clogging: Chili powder is easy to get damp and clump. In order to prevent caking, a humidifier can be set in the chili powder screw conveyor to keep the chili powder dry and avoid caking.

Technical parameters of chili powder screw conveyor

|

Parameter name |

Technical parameter range |

Parameter name |

Technical parameter range |

|

Screw diameter |

100mm-500mm |

Conveying length |

2 m-20m |

|

Conveying capacity |

0.5t/h-10t/h |

Speed |

60-300rpm |

|

Motor power |

0.75kW-7.5kW |

Conveying angle |

0°-90° |

|

Working voltage |

220V/380V |

Weight |

50kg-500kg |

|

Noise level |

≤70dB |

Voltage |

Single-phase or three-phase electricity |

|

Pipe material |

Food grade stainless steel (SUS304/SUS316) |

Screw material |

Stainless steel or spring steel |

|

Feed port size |

200mm×200mm-500mm×500mm |

Discharge port form |

Circular or square, diameter 100-300mm |

Application of chili powder screw conveyor

1. Conveying chili powder to the packaging line after grinding

In the chili powder production workshop, after the chili is washed, dried and ground, the screw conveyor is installed under the grinder. Through inclined conveying, the chili powder is lifted 3-5 meters to the entrance of the packaging machine. The conveying capacity is controlled at 2 tons per hour, and the speed is about 100rpm to ensure that the powder is evenly delivered.

2. Transportation of chili powder before mixing with seasonings

In the production of compound seasonings, chili powder needs to be mixed with other raw materials in proportion. Several small screw conveyors (diameter 150mm) are connected to the chili powder storage silo and other raw material silos respectively.

3. Loading, unloading and transfer of chili powder storage silos

After the chili powder is produced, it needs to be stored in a large silo for subsequent packaging or transportation. After the silo is full, the chili powder needs to be transferred to a truck or a small packaging device.

4. Chili powder distribution in the catering supply chain

The chili powder screw conveyor (diameter 100mm, length 2-3 meters) is installed next to the storage tank. By running at a low speed (60rpm), 1-5 kg of chili powder is conveyed to the packaging machine or above the oil pan each time.

5. Dust recovery in chili powder processing workshop

The chili powder spiral conveyor (diameter 80mm, length 1-2 meters) is connected to the bottom of the dust removal equipment. The collected chili powder dust is sent back to the main silo or packaging line through low-speed conveying (50rpm). The conveying capacity is about 0.1 tons/hour, and the power is 0.75kW.

Application case of chili powder spiral conveyor

A seasoning factory produces 10 tons of chili powder every day. The spiral conveyor directly delivers the powder from the grinding area to the packaging area, which can be completed by one person.

A hot pot base material factory uses 3 spiral conveyors to feed chili powder, pepper powder and spice powder into the mixer, completing 20 batches of mixing per hour.

A chili processing base uses a spiral conveyor to transfer 100 tons of chili powder from the storage silo to the transport vehicle, completing 2-3 loading and unloading per day.

A chili powder factory recycles about 20 kilograms of dust per day through a spiral conveyor, saving costs and improving hygiene levels.

The central kitchen of a chain hot pot restaurant uses a screw conveyor to deliver chili powder to the boiling pot, processing 50 kg of raw materials every day.

Chili powder screw conveyor continuously pushes the chili powder in a closed trough or pipe through the rotating spiral blades, realizing the transportation from the feeding point to the discharging point.