Compost material screw conveyor

Monday March-24 2025 15:26:14

Compost material screw conveyor is a kind of equipment specially used for conveying compost raw materials or finished compost (such as kitchen waste, animal feces, crop straw, etc.), which is widely used in agriculture, waste treatment and organic fertilizer production. In the compost production process, the screw conveyor can effectively convey and mix materials, improve the uniformity and efficiency of compost fermentation.

Working principle of compost material screw conveyor

Compost material screw conveyor mainly relies on the rotating spiral blades to push the material forward, and is usually composed of a drive device, a spiral shaft, a spiral blade, a conveying pipe (or trough), a bracket and other parts.

①Horizontal conveying: suitable for short-distance material conveying, such as conveying from a compost fermentation tank to the next processing equipment.

②Inclined conveying: can be used to convey materials to a higher position, such as from the ground to a fermentation tank.

③Vertical conveying: suitable for scenes with limited space and used when the lifting height is large.

Compost materials suitable for compost material screw conveyor

|

Material type |

Features |

|

Kitchen waste |

Need strong anti-corrosion ability to avoid clogging |

|

Livestock and poultry manure |

The material has a high moisture content and needs to be designed with anti-adhesion |

|

Agricultural straw |

Large volume, can be used with crushing device |

|

Sludge |

High moisture material, needs to be sealed for transportation to prevent leakage |

|

Garden waste |

Need to be crushed before transportation to avoid machine jam |

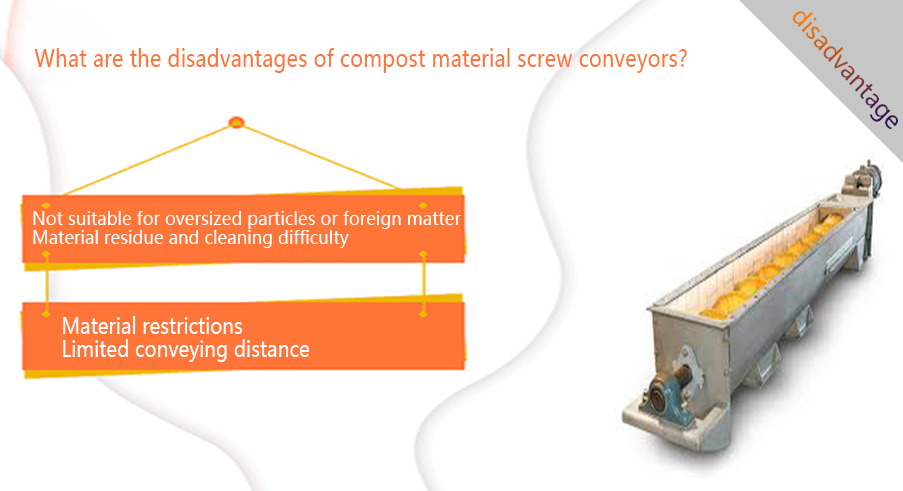

What are the disadvantages of compost material screw conveyors?

1. Not suitable for oversized particles or foreign matter: If large stones, wood blocks or other foreign matter are mixed in the compost material, it is easy to get the screw stuck or damage the blades. Compost material screw conveyor needs to add screening or crushing before feeding, which increases the initial processing cost.

2. Material residue and cleaning difficulty: Although the closed design reduces leakage, it is difficult to completely remove the residual material inside, especially wet and sticky materials. Compost material screw conveyor may breed bacteria or produce odors, affecting hygiene, especially in food-grade composting processing.

3. Material restrictions: Compost material screw conveyor has certain requirements for the shape, size and humidity of the material. For materials that are too wet, too sticky or contain large impurities, blockage is likely to occur, affecting the conveying efficiency.

4. Limited conveying distance: The effective conveying distance of the compost material screw conveyor is usually no more than 20-30 meters. The ultra-long distance needs to be segmented or relayed, which increases the complexity and cost of the equipment and is not suitable for ultra-long distance material handling.

Technical parameters of compost material screw conveyor

|

Parameter name |

typical value / range |

parameter name |

typical value / range |

|

Conveying capacity |

0.5-20 tons / hour |

pipe diameter / slot width |

89mm-580mm |

|

Conveying length |

1-20 meters |

inclination angle |

0°-45° |

|

Screw diameter |

80mm-500mm |

speed |

20-150 rpm |

|

Motor power |

1.5kW-15kW |

voltage |

380V/50Hz (customizable) |

|

Material |

stainless steel 304/316 or carbon steel |

blade thickness |

3mm-10mm |

|

Conveying speed |

0.5-2 meters / second |

weight |

200kg - 2000kg |

|

Working temperature |

-20°C to 60°C |

noise level |

≤75 dB |

Application of compost material screw conveyor

Raw material transportation: transport compost raw materials (such as feces, straw) from the storage area to the fermentation tank or mixing equipment.

Finished product handling: transport the fermented compost to the packaging machine or storage bin.

Fermentation tank extraction: extract compost materials from the bottom of the fermentation tank in anaerobic or aerobic fermentation systems.

Automated production: cooperate with other equipment in the composting production line (such as compost turner, screening machine) to achieve continuous operation.

Application examples

|

Scenario |

conveying capacity |

pipe diameter |

length |

power |

material |

|

Small composting site |

1 ton/hour |

159mm |

5 meters |

2.2kW |

stainless steel 304 |

|

Large organic fertilizer production line |

15 tons/hour |

400mm |

15 meters |

11kW |

stainless steel 316 |

|

Sludge composting |

5 tons/hour |

315mm |

10 meters |

5.5kW |

carbon steel |

Compost material screw conveyor is an indispensable equipment in the composting process, with the characteristics of high efficiency, stability and strong adaptability. When selecting and using, it is necessary to make a reasonable design according to the material characteristics, conveying requirements and site conditions, and regularly maintain it to extend the service life of the equipment.