Concrete batching for screw conveyor

Monday October-23 2023 14:54:32

Concrete batching for screw conveyor product overview

The concrete batching for screw conveyor is a conveying equipment used in the batching process in concrete production. It pushes and transports granular raw materials such as aggregate and sand in the concrete batching to the target location through the rotation of the screw. It has the advantages of being suitable for a variety of granular raw materials, efficient conveying capacity, flexible layout and installation, and reliable working performance. concrete batching for screw conveyors are widely used in the batching process in concrete production, improving work efficiency and production efficiency.

How a concrete batching for screw conveyor works

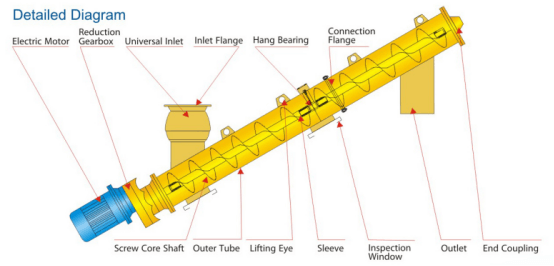

The working principle of the concrete batching for screw conveyor is as follows: the screw conveyor is composed of a screw screw, a bearing seat, a transmission device, an inlet and an outlet, etc. When the spiral screw starts to rotate, the granular raw materials in the concrete batch are pushed onto the spiral blades of the spiral screw, and gradually advance forward as the spiral screw rotates. During the conveying process, the granular raw materials move along the spiral shape of the spiral screw and are finally discharged through the discharge port.

Advantages of concrete batching for screw conveyor

1. Suitable for a variety of granular raw materials: The screw conveyor is suitable for concrete batching raw materials of different particle sizes and densities, including aggregates, sand, etc. It can effectively convey different types and specifications of raw materials.

2. Efficient conveying capacity: The screw conveyor can convey concrete ingredients in a continuous and even manner. It has a large conveying capacity and can meet the batching needs in concrete production.

3. Flexible layout and installation: The screw conveyor can be flexibly laid out and installed according to site conditions. It can be transported horizontally, tilted or vertically to adapt to different working scenarios.

4. Reliable working performance: The screw conveyor is made of wear-resistant and corrosion-resistant materials and has good durability and reliability. It operates stably, reducing breakdowns and maintenance time.

Concrete batching for screw conveyor application

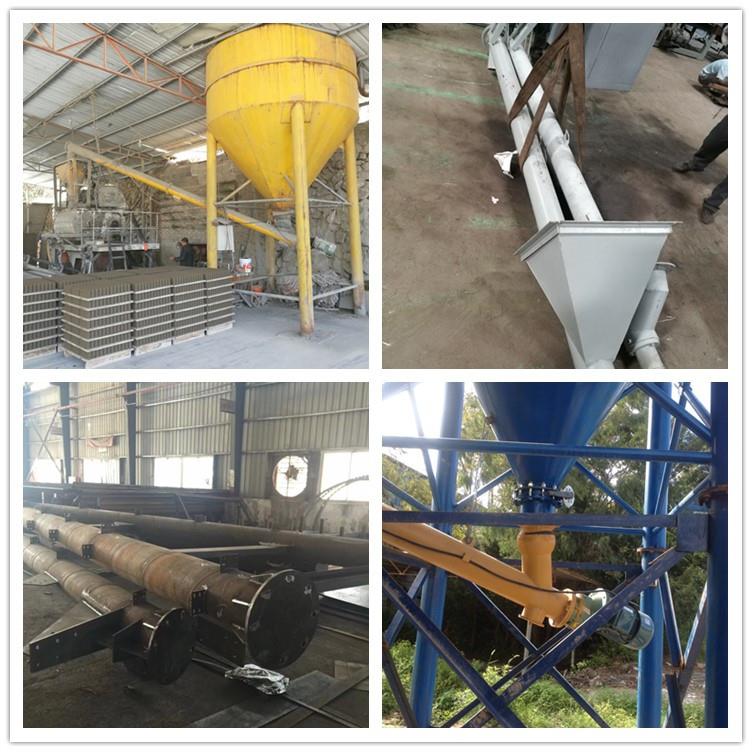

Concrete batching for screw conveyors are widely used in the batching process in concrete production. It can transport aggregates, sand and other raw materials from storage warehouses or production equipment to concrete mixers, mixer trucks or other processing equipment. The use of screw conveyors can improve work efficiency and reduce losses during manual handling and transportation.

Concrete batching for screw conveyor customer usage scenarios

After a concrete production company introduced a concrete batching for screw conveyor in the batching process, the accuracy of batching and production efficiency were improved. The screw conveyor can transport concrete ingredients from the warehouse to the mixer in a stable and continuous manner, reducing the labor intensity and time cost of manual handling. At the same time, the efficient conveying capacity of the screw conveyor improves production efficiency and shortens the production cycle. By using the concrete batching for screw conveyor, the company achieved higher batching accuracy and production efficiency, and achieved obvious economic benefits.