Cooling screw conveyor for rubber char

Thursday September-05 2024 16:59:24

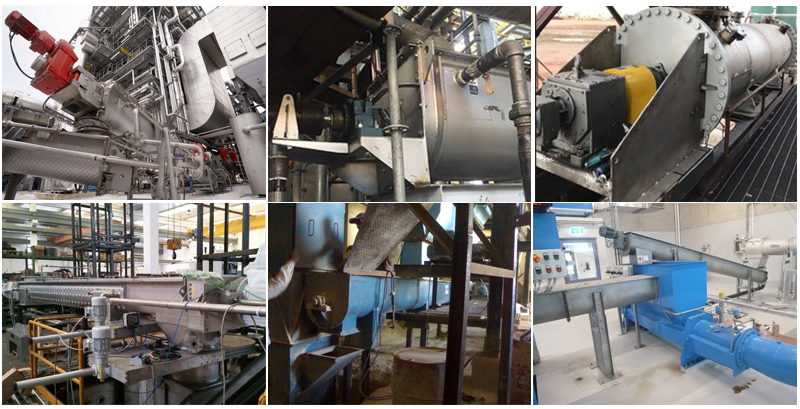

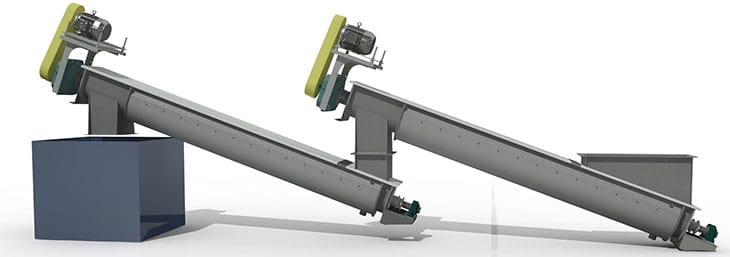

Cooling screw conveyor is a specialized piece of equipment designed to efficiently transport and cool rubber char, a byproduct of the rubber tire recycling process.

How it Works?

Cooling screw conveyor for rubber char works by moving the rubber char along the screw while simultaneously introducing cool air or water to lower the temperature of the material. This helps prevent overheating and ensures that the rubber char remains at the desired temperature for further processing or storage.

Material Feeding: Rubber char is fed into the inlet of the conveyor.

Conveying and Cooling: As the screw rotates, it propels the rubber char along the conveyor trough. Simultaneously, cold air or liquid is introduced into the conveyor, which helps to cool down the hot rubber char.

Discharge: The cooled rubber char is discharged from the outlet of the conveyor.

Features of cooling screw conveyor for rubber char

Efficient Cooling: The screw conveyor's design and cooling mechanism ensure rapid and effective cooling of the rubber char, preventing overheating and material degradation.

Gentle Handling: The screw's gentle action minimizes damage to the rubber char particles, preserving their quality and value.

Continuous Operation: Screw conveyors can operate continuously, providing a steady flow of cooled rubber char.

Customization: They can be customized to meet specific process requirements, including conveyor length, material of construction, and cooling method.

Versatility: Screw conveyors can also be used to transport other materials, such as powders, granules, and flakes.

Applications of cooling screw conveyor for rubber char

Rubber Tire Recycling: Cooling rubber char before further processing, such as pelletizing or carbon black production.

Material Handling: Transporting rubber char between different processing stages.

Waste Management: Handling and cooling rubber char as part of waste management operations.

Factors to consider when selecting a cooling screw conveyor

Rubber Char Properties: The temperature, moisture content, and particle size of the rubber char will influence the conveyor's design and cooling method.

Throughput Requirements: The desired rate of material flow will determine the conveyor's capacity.

Space Constraints: The available space for installation will impact the conveyor's length and configuration.

Cooling Method: The choice between air cooling and liquid cooling depends on factors such as cooling efficiency, energy consumption, and environmental considerations.

By carefully considering these factors, you can select the most suitable cooling screw conveyor for your rubber char processing needs.

The cooling screw conveyor for rubber char is designed to effectively and efficiently cool down the material while also providing gentle handling to prevent damage to the rubber char particles. It is commonly used in rubber manufacturing plants and tire recycling facilities to cool down the rubber char before it is used in other processes or products.