Corn truck-mounted grain suction machine

Saturday February-15 2025 17:18:23

Corn truck mounted grain suction machine is a kind of equipment specially used for collecting, conveying and processing corn and other grains and granular crops. It is usually installed on a vehicle for easy movement and use. It can efficiently suck corn grains scattered in the fields into the machine and transport the corn to the designated location through the conveying pipe, which greatly reduces the labor intensity of farmers and improves the work efficiency.

Video of corn truck-mounted grain suction machines

What are the applicable materials for corn truck-mounted grain suction machines?

1. Corn: Corn is one of the main materials handled by truck-mounted grain suction machines. This equipment is designed to efficiently collect and convey corn.

2. Wheat: Although mainly designed for corn, some truck-mounted grain suction machines can also be used to collect and process grains such as wheat.

3. Soybeans: Some truck-mounted grain suction machines can also be used to collect and convey beans such as soybeans.

4. Grain mixtures: Truck-mounted grain suction machines can usually handle mixtures of multiple grains, such as a mixture of corn and wheat.

5. Other grains: Depending on the design and specifications of the equipment, truck-mounted grain suction machines may also be used to process other grains, such as millet, oats, rice, etc.

Main features of corn truck-mounted grain suction machines

High efficiency: It can transport a large amount of corn in a short time, with a conveying capacity of up to 3-25 tons per hour, and can quickly complete the loading and unloading and conveying of wheat, greatly improving the efficiency of corn loading and unloading and transportation.

Strong mobility: It can be installed on the vehicle and can be flexibly moved to different locations such as farmland, grain depot, dock, etc. to adapt to different working scenes.

Low damage rate: With unique spiral spring structure and conveying method, the spiral grain sucker has less friction and extrusion on corn, and the pneumatic grain sucker relies on air flow to convey, which has less damage to wheat, and can effectively reduce the breakage rate of corn.

Versatility: In addition to sucking wheat, it can also be used to suck other granular grains such as corn, soybeans, and rice, and can also suck granular fertilizers, feed, chemical products and other non-corrosive granular materials.

What are the disadvantages of corn truck-mounted grain suckers?

1. Power limitation: Electric corn truck-mounted grain suckers require an external power supply. If they are operated in remote areas without power supply, they need to be equipped with additional power supply equipment such as generators, which increases the cost and complexity of operation. Although gasoline and diesel models do not require an external power supply, they need to consume fuel, have high operating costs, and the engine requires regular maintenance.

2. Limited conveying capacity: Although the conveying efficiency of corn truck-mounted grain suckers is relatively high, its conveying capacity is still limited compared with some large fixed conveying equipment. For large-scale corn loading and unloading operations, multiple devices may be required to operate simultaneously or take a long time to complete.

3. High equipment maintenance requirements: Key components such as spiral springs and fans are prone to wear and failure after long-term use, and need to be regularly inspected, maintained and replaced. The pipelines of pneumatic grain suckers may also be blocked, leaked, and other problems, affecting the conveying efficiency, and the maintenance cost and difficulty are relatively high.

4. Affected by the environment: Under severe weather conditions, such as strong winds and heavy rains, the operating efficiency and safety of the corn truck-mounted grain sucker will be affected to a certain extent.

5. High initial investment cost: The price of purchasing a corn truck-mounted grain sucker is relatively high, and for some small farmers or grain operators, it may require a large capital investment.

Application of corn truck-mounted grain suction machine

Agricultural production field: Farmers can directly suck the freshly harvested corn from the field to the transport vehicle, realize fast loading, and transport the corn to the sales point or storage location in time. The corn truck-mounted grain suction machine can collect the corn harvested from different plots in the centralized operation area of the farm and transport it to large storage equipment or transport vehicles.

Grain storage field: The corn truck-mounted grain suction machine can be used for corn storage and outbound operations. Quickly suck the corn in the transport vehicle into the grain warehouse, or suck the corn in the warehouse to the transport vehicle when it needs to be outbound. The grain warehouse sometimes needs to reverse the corn, that is, transfer it from one warehouse to another.

Grain processing field: When corn processing enterprises receive corn raw materials, the corn truck-mounted grain suction machine can quickly transport the corn in the transport vehicle to the raw material storage area of the processing workshop or directly to the feed port of the processing equipment, realize automatic feeding, and improve the efficiency of processing and production.

Grain transportation field: The corn truck-mounted grain suction machine can be used for fast loading and unloading of transport vehicles. Load corn at the grain procurement point. At grain transshipment sites such as railway freight yards or docks, corn from road transport vehicles is sucked onto railway trucks or transport ships, achieving efficient connection between different modes of transportation.

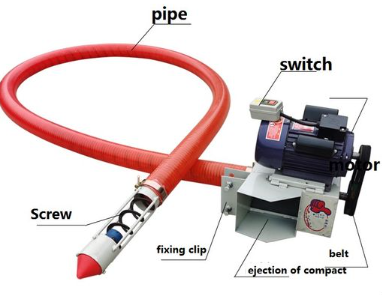

Structural of corn truck-mounted grain suction machine

1. Driving device: usually a high-power motor and a matching reducer are used to provide sufficient power to lift a large amount of materials. It may also be equipped with a frequency conversion speed regulation device to adjust the lifting speed according to actual production needs.

2. Tensioning device: screw adjustment tensioning or heavy hammer tensioning are used to ensure that the chain or belt maintains proper tension during operation to prevent slipping and excessive wear.

3. Chain and hopper assembly: The chain generally uses high-strength plate chain or forged chain to withstand the weight of large-capacity materials and the pulling force during lifting. The hopper is usually made of large-capacity, high-strength materials, such as wear-resistant steel plates, and the shape is designed according to the characteristics of the material, including deep hoppers, shallow hoppers, pointed bottom hoppers, etc.

4. Feeding device and discharging device: The feeding device is located at the bottom of the casing, and chutes, vibrating feeders, etc. are often used to ensure that the material can enter the hopper evenly and quickly. The discharge device is located at the top of the casing. Through the reasonably designed discharge port and discharge method, the material can be discharged smoothly to the designated location.

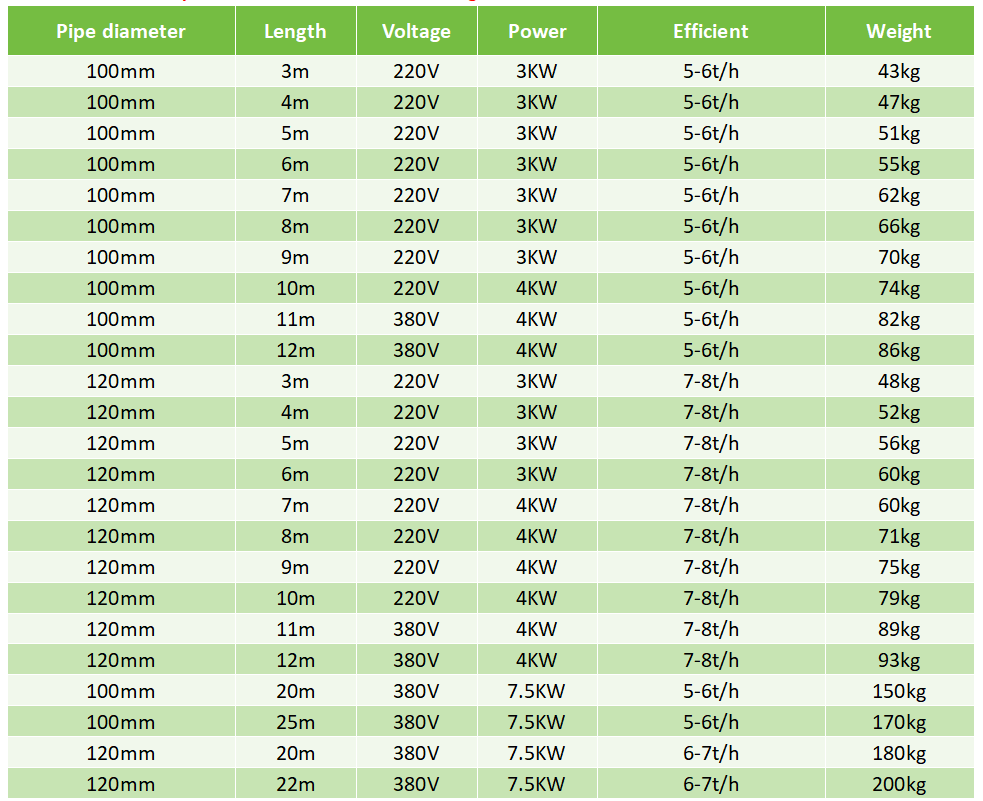

Technical parameters of corn truck-mounted grain suction machine

Selection suggestions for corn vehicle-mounted grain suction machine

1. Suction size: For large output, choose a model with large suction; for small output, choose a model with moderate suction. The longer the conveying distance, the greater the suction required. Excessive suction may cause pipeline blockage, which should be considered comprehensively.

2. Conveying distance: The conveying distance at different work sites is different, so choose a suitable pipe length. Too small pipe diameter will increase resistance and affect conveying efficiency.

3. Filter material: The filter should be wear-resistant to prevent wear by corn kernels. Choose a suitable aperture according to the size of corn kernels, which can filter impurities and ensure smooth flow.

4. Motor power: The larger the conveying volume, the greater the motor power required. Choose a motor that matches the local power supply voltage.

5. Vehicle chassis: The chassis should be stable to ensure the stability of the equipment during operation. Consider the complexity of the working environment and choose a suitable chassis.

Corn truck mounted grain suction machine is a grain suction device installed on a vehicle, which is specially used to quickly and efficiently absorb and convey granular grains such as corn. It combines the advantages of grain suction machines and vehicles, and is suitable for a variety of scenarios such as fields, granaries, trucks, etc. It can significantly improve the efficiency of grain loading and unloading and transportation, and reduce manual labor intensity.