Detailed structure and application range of plate chain bucket elevator (attached application range table)

Friday November-18 2022 15:15:10

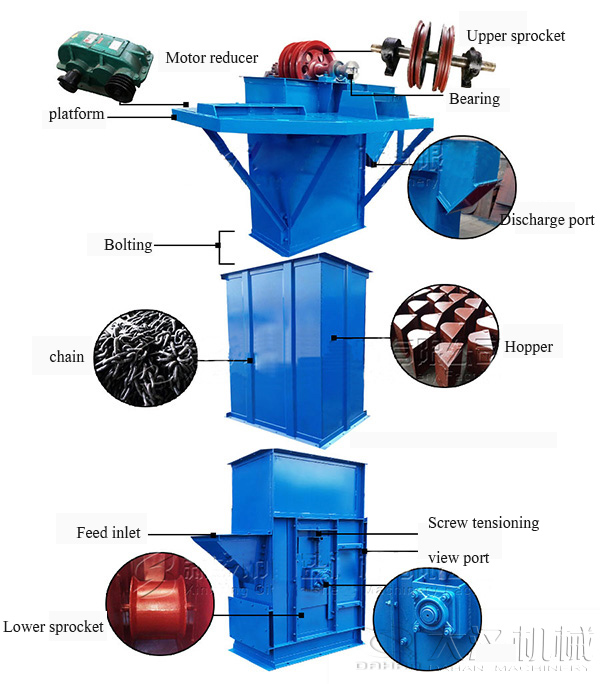

The plate chain bucket elevator is what we often call the NE bucket elevator. The overall model is small and the lifting capacity is strong. The NE plate chain bucket elevator consists of the running part, the driving device, the head device, the middle shell and the tail device. composition.

1. The running part can be said to be the main part of the whole machine, which is composed of a hopper and a plate roller chain. The volume of the hopper is 1.8L, 4.0L and 6.0L, etc. The hopper can be customized. Roller chains can be divided into single-strand chains and double-strand chains. Single-strand chains are used for NE15 and NE30, and double-strand chains are used for NE50-NE500.

2. The driving device is composed of a driving platform, a driving combination and a transmission chain.

The driving device can be divided into left driving device, right driving device and double driving device, and the driving device is mainly adjusted according to the situation of the production site.

(1) Assembly on the left side: the staff faces the feed inlet, and the driving device is assembled on the left side.

(2) Assembly on the right side: the staff faces the feed inlet, and the driving device is assembled on the right side.

(3) Double drive: the staff faces the feed inlet, and the drive devices are combined on both sides.

3. The middle shell: it mainly houses the middle section of the inspection door of the machine and the connection of the machine section, the standard section (2m) and the non-standard section (1~1.5m).

4. The tail device is equipped with a tensioning device, NE15-50 is for spring tensioning, and NE100-500 is for dropping hammer tensioning.

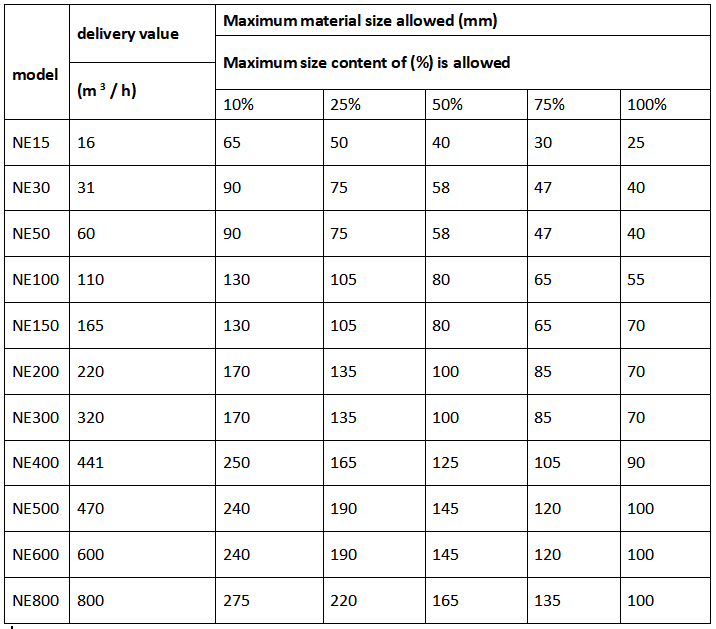

Application range

Plate chain bucket elevators usually convey heavy and abrasive materials such as stone, stone powder, and grain, and can be used for bulk materials of various scales such as feed mills, flour mills, rice mills, grain depots, stone factories, and chemical plants. The structure of the metal plate chain can withstand 250 ℃ high temperature materials.