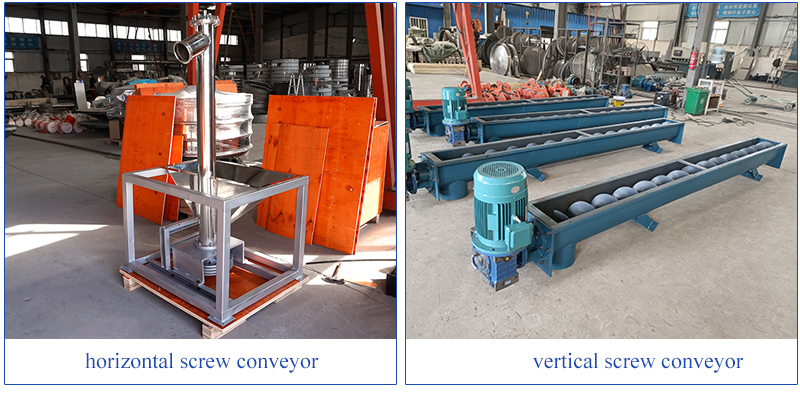

Difference between horizontal screw conveyor and vertical screw conveyor

Friday March-25 2022 09:47:40

Screw conveyor according to the transmission angle can be divided into horizontal, tilt and vertical three categories, this paper will mainly introduce you to the difference between horizontal screw conveyor andvertical screw conveyor :

Difference 1:Working principle

Vertical screw conveyor working principle: the use of rotating spiral blade material along the spiral displacement direction forward, material in the process of conveying by rotating spiral centrifugal force, as well as its own gravity and the role of friction between the housing, so as to achieve the effect of upward transportation.

Horizontal screw conveyor working principle: by rotating spiral blade material along the direction of displacement transport, relying on the material itself gravity and screw conveyor casing of material friction double force; And the material in the middle bearing displacement, rely on the material behind the forward movement of the thrust and transport.

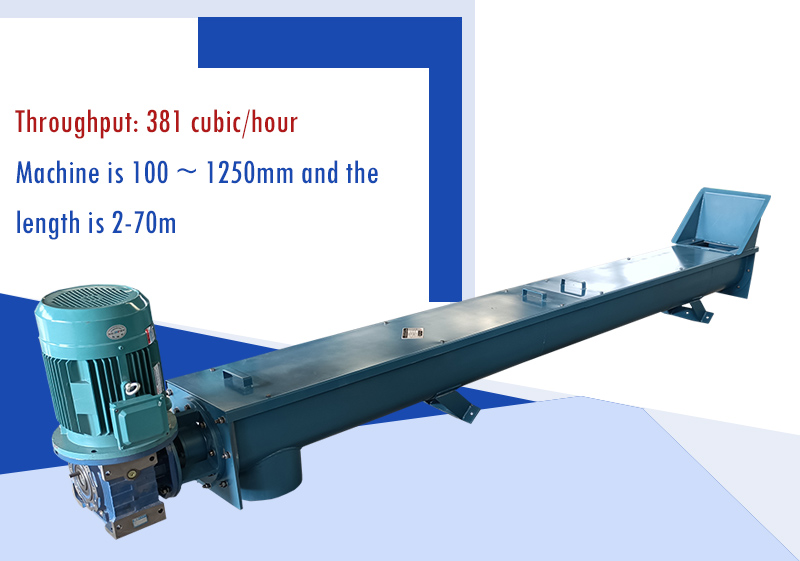

Difference 2:Throughput

Vertical screw conveyor throughput: 140 cubic/hour.

Horizontal screw conveyor throughput: 381 cubic/hour.

Difference 3:Conveying height

Vertical spiral conveying height: from 2.5 meters to 15 meters, 0.5 meters is a grade, users can choose conveying height according to their needs.

Horizontal screw conveyor conveying length: the screw diameter of the machine is 100 ~ 1250mm and the length is 2-70m, special specifications can be produced according to customer demand.

Difference 4:Transmission Angle

Vertical screw conveyor is suitable for vertical 90° direction of conveying powder, granular, non-viscous bulk density ≤ 1.3T /m dry materials, horizontal screw conveyor is suitable for horizontal or slightly inclined (≤20°) continuous uniform transport of loose materials.

If you want to know more about the difference between horizontal screw conveyor and vertical screw conveyor, please consult us