Dust removal screw conveyor

Wednesday December-25 2024 18:21:39

Dust removal screw conveyor is designed to convey and remove dust and fine particles generated in various industrial processes,Dust removal is usually solid particulate matter collected in dust removal equipment (such as dust collector). These dust removal ash usually need to be transported to corresponding treatment facilities or processing sites for further treatment or disposal.

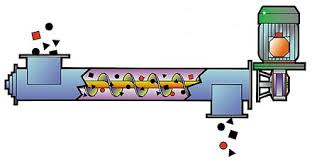

Working principle of dust removal screw conveyor

Material feeding: solid granular dust ash enters the spiral cavity of the screw conveyor from the feed port.

Screw transmission: a screw shaft is provided inside the screw conveyor. When the screw shaft rotates, the spiral blade pushes the material along the direction of the screw shaft.

Conveying material: the rotation of the spiral blade pushes the dust ash to move in the conveying direction, and gradually conveys it to the discharge port along the spiral cavity of the conveyor.

Function of dust removal screw conveyor

The dust removal screw conveyor plays an important role in industrial production. Its main functions include:

Transporting dust ash: The main function of the dust ash screw conveyor is to transport the solid granular waste (i.e. dust ash) collected from the dust removal equipment from one location to another for further processing or disposal.

Controlling dust diffusion: Through sealing design and appropriate conveying methods, the dust ash screw conveyor helps to control and reduce the dust diffusion of dust ash during the transportation process and keep the production environment clean.

Application of dust removal screw conveyor

The dust removal screw conveyor is widely used in the industrial field, especially for handling and conveying various types of dust ash. The following are some applications:

The dust removal equipment system is usually used in conjunction with the dust removal equipment system to collect and convey solid particulate matter from the dust collector and transport the dust ash from the collection point to the processing or disposal facility.

Coal-fired power plant: The smoke and ash generated by coal combustion need to be processed by dust removal equipment, and the dust ash screw conveyor is used to collect and convey these ash slags.

Metallurgical industry: solid wastes such as slag and slag are processed by dust removal equipment, and the dust removal ash screw conveyor is used to transport these wastes to the corresponding treatment facilities.

Cement production: often used to transport these wastes to crushers or grinding mills and other equipment for further processing.

Chemical industry: can be used to transport these wastes to the corresponding treatment units.

Advantages of dust removal screw conveyor

Improved dust control: Significantly reduces dust emissions and improves workplace air quality.

Enhanced safety: Minimizes the risk of dust explosions and employee exposure to hazardous dusts.

Improved Efficiency: Simplifies dust collection processes and increases overall productivity.

Reduced Maintenance: Rugged construction and reliable operation minimize maintenance requirements.

Cost-effectiveness: helps create a cleaner, safer and more efficient production environment.

Dust removal screw conveyor selection considerations

Here are some key things to note when choosing a dust removal screw conveyor:

Conveying requirements: Determine the properties of the dust to be conveyed, including particle size, density, humidity, etc., to ensure that the selected screw conveyor can effectively handle these materials.

Conveying distance and angle: Consider the conveying distance and angle, and select the appropriate screw conveyor size and length to ensure that it can meet actual needs.

Processing capacity: Select the appropriate screw conveyor processing capacity based on the amount of dust to be processed per hour to ensure that production needs are met.

Conveying speed: Determine the required conveying speed based on the requirements of the production line and the characteristics of the material, and select the appropriate screw conveyor speed and power.

Environmental requirements: Consider the working environment conditions, such as temperature, humidity, etc., and select a screw conveyor with corrosion resistance, high temperature resistance or dustproof sealing characteristics.

By incorporating dust removal screw conveyors into dust collection systems, businesses can significantly enhance their environmental performance, improve workplace safety, and optimize their production processes.