Explosion proof fertilizer granule suction machine

Wednesday February-19 2025 17:20:57

Explosion proof fertilizer granule suction machine is a type of suction machinery specifically designed for transporting fertilizer granules and has explosion-proof function, ensuring safety when handling flammable or explosive granules. It is mainly used in fertilizer production, storage, transportation and other links, which can effectively improve work efficiency, reduce labor intensity, and ensure safe production.

What types of materials can explosion proof fertilizer granule suction machine handle?

Fertilizer particles: Explosion proof fertilizer particle suction machine is mainly used to process fertilizer particles, including various types of fertilizer particles such as nitrogen fertilizer, phosphorus fertilizer, potassium fertilizer, etc.

Grain: Explosion proof fertilizer granule suction machine can also be used to process grain granules, such as grains, rice, wheat, etc.

Seeds: When processing seed particles, explosion-proof fertilizer particle suction machines can also be used to help transport and process seeds.

Granular fertilizers: In addition to fertilizer granules, other granular fertilizers such as organic fertilizers, compound fertilizers, etc. can also be processed.

Other granular materials: The explosion-proof fertilizer granule suction machine can also handle other granular materials, such as plastic granules, wood chips, etc.

What is the function of the Explosion proof fertilizer granule suction machine?

The most important feature of Explosion proof fertilizer granule suction machine is its explosion-proof function. Due to the production and transportation of fertilizers, dust may be generated, and when the dust reaches a certain concentration, it may explode when exposed to open flames or static electricity. Therefore, the explosion-proof grain suction machine adopts various explosion-proof measures.

1. Explosion proof motor: Adopting explosion-proof design to avoid generating electric sparks.

2. Anti static materials: Use anti-static materials to reduce static electricity generation.

3. Sealing structure: Adopting a sealing structure to prevent dust leakage.

4. Overload protection: With overload protection function, it can avoid accidents caused by motor overload

How do explosion proof fertilizer granule suction machines work?

When the explosion proof fertilizer particle suction machine is working, the motor drives the fan to generate high-speed airflow, which sucks in the fertilizer particles through the suction pipe, and then transports them to the separator through the conveying pipe under the drive of the airflow. In the separator, fertilizer particles are separated from the airflow, and the particles fall into the silo or conveyor belt, while the airflow is filtered and discharged.

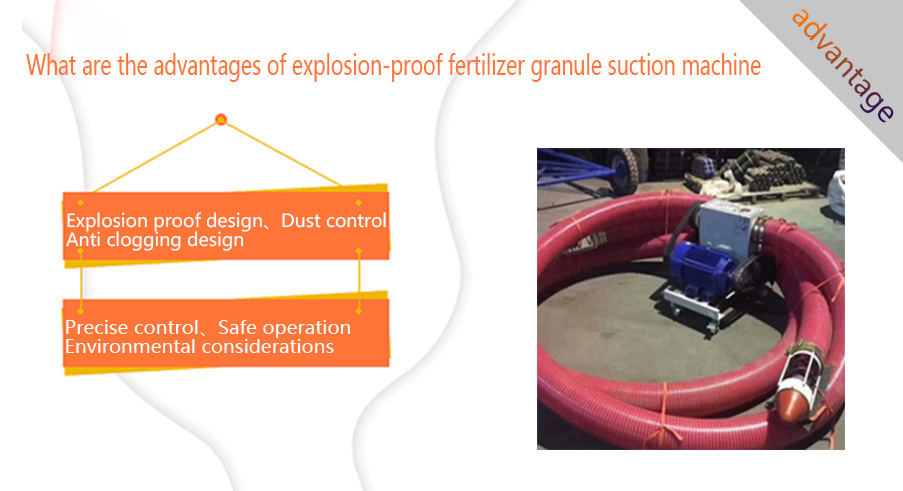

What are the advantages of explosion-proof fertilizer granule suction machine

1. Explosion proof design: The explosion-proof grain suction machine adopts explosion-proof design, including the use of explosion-proof motors, explosion-proof electrical equipment, explosion-proof valves and other safety measures to prevent dust explosions and ensure the safety of fertilizer particles during transportation.

2. Dust control: Explosion proof grain suction machines are usually equipped with dust collection equipment, which can effectively control the dust generated during particle transportation and reduce the impact of dust on the environment and workers.

3. Anti clogging design: Explosion proof grain suction machines are designed with consideration for particle clogging, usually using special structures and materials to reduce the possibility of particle clogging and ensure smooth particle transportation.

4. Precise control: Explosion proof grain suction machines are usually equipped with precise control systems that can adjust the conveying speed and quantity as needed to ensure accurate transportation of fertilizer particles.

5. Safe operation: Operators must strictly follow the operating procedures when using explosion-proof grain suction machines to ensure the safe operation of the equipment and avoid safety issues caused by improper operation.

6. Environmental considerations: The explosion-proof grain suction machine has also taken into account environmental factors in its design and use, ensuring compliance with environmental requirements when processing fertilizer particles and reducing its impact on the environment.

The structure of explosion proof fertilizer granule suction machine

Suction tube: used to suck in food. Its design needs to consider the fluidity of materials and avoid blockages.

Conveyor pipe: used to transport inhaled food. The material and structure of the conveying pipe may vary depending on the type of grain suction machine.

Power unit: This is the core component of the grain suction machine, providing suction and conveying power. There are two common types: motors and fans. The motor directly drives the spiral blades of the spiral grain suction machine, while the fan provides high-speed airflow for the pneumatic grain suction machine.

Discharge outlet: used to discharge separated grains. The location and design of the discharge port need to take into account the subsequent material handling methods.

Rack and support structure: used to support and fix various components of the grain suction machine, ensuring stable operation of the equipment.

What is the explosion proof fertilizer granule suction machine used for?

1. Fertilizer production enterprises: In the fertilizer production workshop, it is used to transport the produced fertilizer particles from the production equipment to the packaging workshop or storage warehouse, realizing automated transportation in the production process, improving production efficiency, reducing labor intensity and safety risks of manual handling.

2. Agricultural planting base: In large-scale agricultural planting bases, it is used to transport fertilizer particles from storage warehouses to the fields, facilitating farmers' fertilization operations. Fertilizer particles can be directly transported to fertilization equipment to achieve precise fertilization.

3. Grain storage and logistics enterprises: used in conjunction with grain conveying systems to transport fertilizer particles used for fertilizing grain crops, transporting fertilizers from storage areas to fertilizer stations in grain drying, processing, and other stages.

Explosion proof fertilizer granule suction machine is an indispensable and important equipment in the production, storage, and transportation of fertilizers. By selecting and using correctly, work efficiency can be effectively improved, labor intensity can be reduced, and safety production can be ensured.