Fertilizer belt conveyor

Monday March-24 2025 15:56:48

Fertilizer belt conveyor is a mechanical device that continuously transports various fertilizers from the feeding point to the unloading point through the circular motion of an endless belt (conveyor belt). It is suitable for horizontal, inclined or short-distance vertical transportation and can efficiently handle granular, powdered or bagged fertilizers. This conveyor is widely used in industries such as agriculture and fertilizer production because it can efficiently and stably transport large amounts of fertilizers, thereby improving production efficiency.

Fertilizer belt conveyor handling materials

Aggregates, Frac Sand, Gypsum, Limestone, Clinker, Gravel, Slag, Filter Dusts

Coal, Lignite, Copper Ore, Iron Ore, Nickel, lithium Ore, Alumine, Gold Ore, Zinc Ore

Animal Feeds, Grain, Salt, Sugar, Biomass Fuel, Municipal Waste, Sewage Sludge, Woodchips

Fertilizer, Urea, Inorganic Chemicals,Organic Chemicals, Petroleum Coke, Potash, Pulp&Paper

Working principle of fertilizer belt conveyor

1. The fertilizer belt conveyor is mainly composed of a drive device, a conveyor belt, rollers, a drum and a frame.

2. The drive device drives the drum to rotate, and the drum drives the conveyor belt to move through friction.

3. The fertilizer is placed on the conveyor belt and is transported to the destination as the conveyor belt moves.

4. The rollers are used to support the conveyor belt to prevent it from sagging.

The structure of the fertilizer belt conveyor

The main components of the fertilizer belt conveyor include the belt, drive device, roller, tensioning device, feeding device, discharging device and frame. The belt is the core component for carrying and conveying fertilizer. The drive device provides power, and the roller supports the weight of the belt and fertilizer to reduce friction resistance.

What are the advantages of fertilizer belt conveyors?

1. Solve the moisture problem of fertilizers: For fertilizers that are susceptible to moisture, fertilizer belt conveyors can use moisture-proof belts and maintain a dry environment during transportation. In a humid environment, increase the conveying speed, reduce the time that fertilizers are exposed to a humid environment during transportation, reduce the moisture of fertilizers, and prevent agglomeration.

2. Avoid the problem of fertilizer particle breakage: The fertilizer belt conveyor can adjust the running speed, reduce the collision and friction of fertilizer particles during transportation, and reduce breakage. Install a buffer device at the feed port to reduce the impact of the falling fertilizer particles. Use a flexible belt material to reduce the extrusion and wear of fertilizer particles.

3. Long-distance transportation: For long-distance transportation, the fertilizer belt conveyor can use a multi-section belt conveyor in series to ensure transportation efficiency. In long-distance transportation, add a power device (such as an intermediate drive) to prevent the belt from slipping or insufficient power.

4. Adaptation to complex terrain: The fertilizer belt conveyor supports horizontal, inclined or curved transportation to meet the needs of complex terrain. It can be moved as needed to flexibly adapt to different sites.

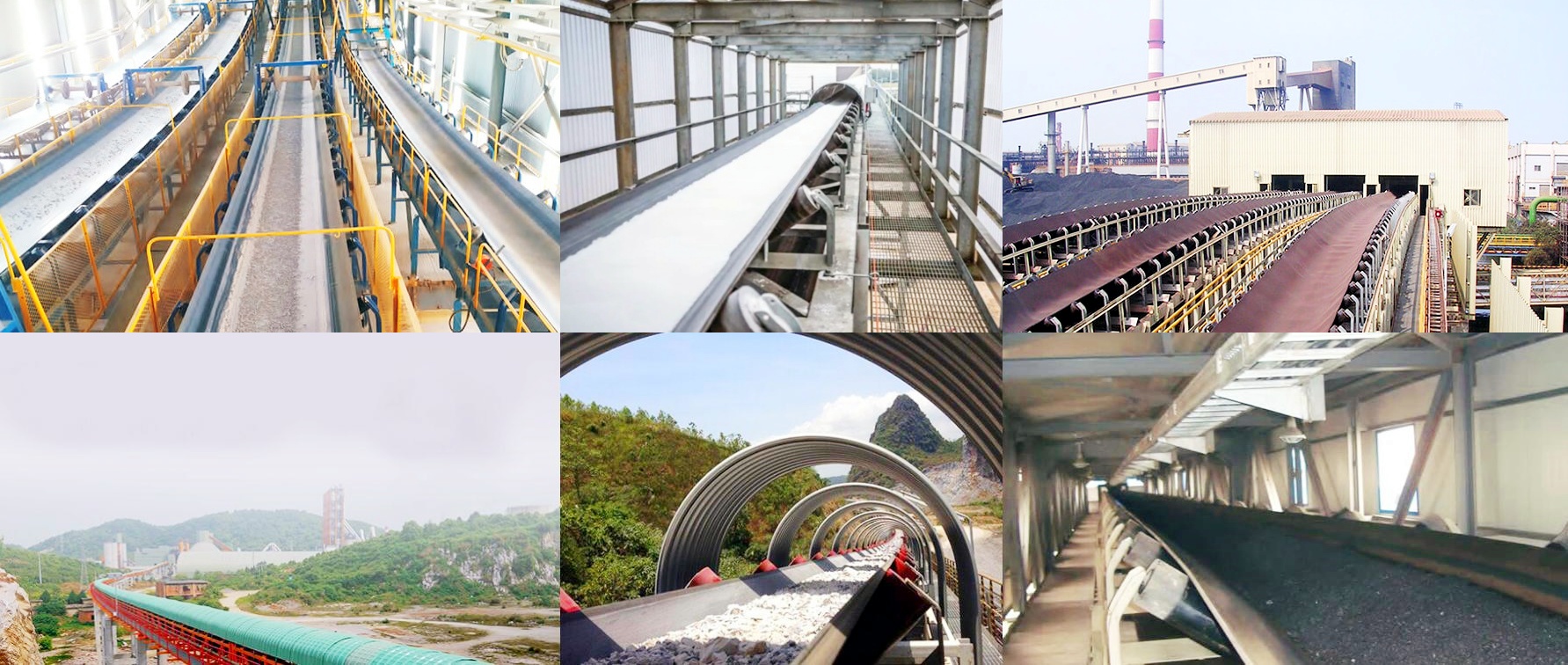

Application of Fertilizer Belt Conveyor

1. Fertilizer production workshop: Fertilizer belt conveyor is used to transport the produced fertilizer from the reactor, granulator and other equipment to the packaging machine or storage warehouse to realize the material transfer in the fertilizer production process.

2. Fertilizer warehouse: It is used to stack, transport and load and unload fertilizer in the warehouse to facilitate the storage and management of fertilizer. For example, the bagged fertilizer is transported from the loading and unloading platform to the designated location inside the warehouse, or the fertilizer is transported from the storage area of the warehouse to the loading area.

3. Ports and docks: In ports, docks and other places, it is used to unload fertilizer from transport ships to the shore, or load fertilizer on the shore onto ships to realize the connection between water and land transportation of fertilizer.

4. Agricultural planting base: In large agricultural planting bases, it is used to transport fertilizer from storage points to fields to facilitate farmers to carry out fertilization operations and improve fertilization efficiency.

Recommended mesh count for fertilizer belt conveyor handling materials

|

Material type |

Particle size range |

Recommended mesh count |

Application scenario |

|

Granular compound fertilizer |

1-4mm |

4-10 mesh |

Screen large-particle compound fertilizer to remove impurities |

|

Powdered diammonium phosphate |

0.1-1mm |

20-60 mesh |

Screen powder fertilizer to ensure uniform particle size |

|

Urea granules |

1-3mm |

6-12 mesh |

Screen urea granules to remove fine powder |

|

Potassium fertilizer granules |

2-5mm |

4-8 mesh |

Screen potassium fertilizer granules to ensure consistent particle size |

|

Organic fertilizer powder |

0.1-0.5mm |

40-100 mesh |

Screen organic fertilizer powder to remove large-particle impurities |

|

Compost material |

1-10mm |

2-8 mesh |

Screen compost to separate large impurities |

Operation precautions for fertilizer belt conveyor handling materials

① Pre-startup inspection: Confirm that the material mesh count matches the equipment parameters to avoid overload.

②Regular maintenance: Check the conveyor belt wear every 2 hours, and increase the cleaning frequency when the mesh size is greater than 60 mesh.

③Emergency treatment: When fine particles are blocked, use compressed air to blow (pressure ≤ 0.4MPa).

Typical case reference

|

Mesh range |

Material characteristics |

Recommended configuration |

Effect |

|

10~20 mesh |

Organic fertilizer particles |

Belt width 800mm, belt speed 2.0m/s |

Transport efficiency 250t/h, no blockage |

|

40~60 mesh |

Powdered compound fertilizer |

Belt width 600mm, belt speed 1.5m/s |

Dust reduction 70%, energy consumption reduction 15% |

|

>100 mesh |

Ultrafine mineral additives |

Belt width 500mm, belt speed 1.0m/s |

Material breakage rate <0.3%, high stability |

Fertilizer belt conveyor manufacturer

Fertilizer belt conveyor is a stable conveying equipment, which is widely used in fertilizer production, storage, loading and other links. It continuously transports fertilizer through the belt, has the advantages of strong adaptability, easy maintenance, customization, etc., reduces labor intensity, reduces fertilizer loss, and is an important equipment for modern fertilizer production and logistics.