Flexible screw conveyor for extruded feed

Tuesday April-01 2025 11:44:58

Flexible screw conveyor for extruded feed is a mechanical conveying system specially used for conveying extruded feed, which is usually used in feed processing, aquaculture or pet food production. It uses flexible spiral blades to rotate in a pipe or trough, and the extruded feed is transported from one location to another through the pushing action of the spiral. Flexible screw conveyor for extruded feed can handle powdered, granular or small block materials, and is particularly suitable for light and fragile materials such as extruded feed.

Video of the flexible screw conveyor for extruded feed

How does the flexible screw conveyor for extruded feed work?

Flexible screw conveyor for extruded feed pushes the material from one end to the other by rotating a flexible screw body (usually made of wear-resistant materials such as stainless steel or high-strength plastic) in a tubular or trough-shaped shell. Its design allows horizontal, inclined and even vertical conveying to adapt to different production layouts. The extruded feed can maintain the integrity of the particles during the conveying process to avoid excessive crushing or dust generation.

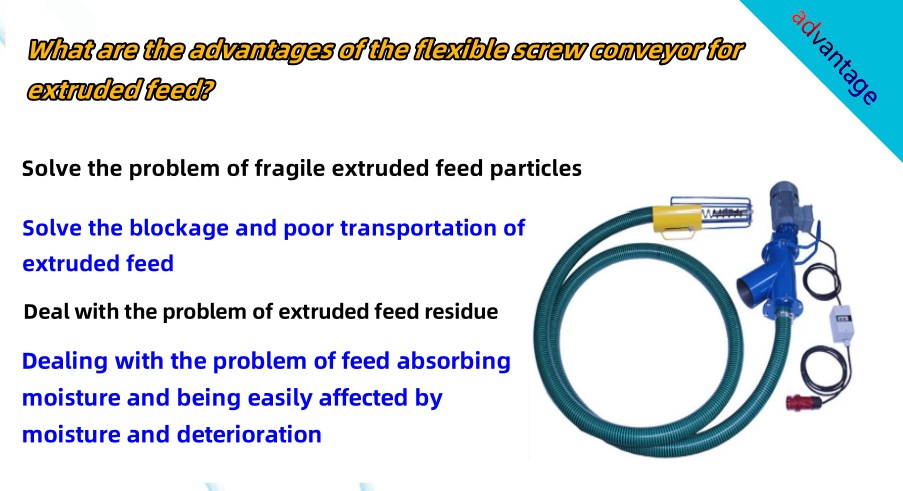

What are the advantages of the flexible screw conveyor for extruded feed?

1. Solve the problem of fragile extruded feed particles

If extruded feed (such as fish food and pet food) is squeezed or rubbed at high speed during transportation, it is easy to break, affecting the integrity of the particles. The spiral speed of the flexible screw conveyor for extruded feed is adjustable to reduce the impact force on the material and reduce the breakage rate.

2. Solve the blockage and poor transportation of extruded feed

extruded feed particles are of different sizes or stick together due to humidity changes, which can easily cause blockage during transportation, especially when transporting over long distances or at high angles. The continuous rotation of the flexible screw conveyor for extruded feed has a certain self-cleaning effect, reducing material accumulation.

3. Deal with the problem of extruded feed residue: Extruded feed is easy to adhere to the inner wall or gap of the conveying equipment, causing material residue. If different types of feed are transported, cross contamination may occur. The inner wall of the flexible conveying pipe of the flexible screw conveyor for extruded feed is smooth, which reduces the adhesion of materials.

4. Dealing with the problem of feed absorbing moisture and being easily affected by moisture and deterioration:

Extruded feed easily absorbs moisture in a humid environment, causing the feed to swell and clump. Flexible screw conveyor for extruded feed uses a closed conveying pipeline to prevent moisture from the outside air from entering and reduce the risk of feed getting damp. It is suitable for outdoor transportation or humid environments.

Technical parameters of flexible screw conveyor for extruded feed

|

Parameter name |

specification/range |

parameter name |

specification/range |

|

Conveying capacity |

1-10 tons/hour |

conveying distance |

1-30 meters |

|

Applicable particle size |

1-15mm |

material bulk density |

0.4-0.8g/cm³ |

|

Conveying angle |

0°-60° |

screw diameter |

38mm/55mm/75mm/90mm |

|

Pipe material |

PVC/stainless steel |

screw material |

carbon steel/stainless steel/nylon |

|

Motor power |

0.75kW-5.5kW |

voltage |

220V/380V |

|

Speed |

200-400 r/min |

Applicable materials |

extruded feed, pellet feed, powdered feed, etc. |

|

Rated conveying capacity |

1-20t/h (customizable) |

Maximum conveying length |

horizontal ≤ 20m, vertical ≤ 8m |

|

Maintenance method |

regular cleaning, inspection of spiral blade wear |

speed range |

20-60rpm (adjustable frequency control) |

Application of flexible screw conveyor for extruded feed

1. Aquatic feed processing plant

During the production process, feed needs to go through multiple links such as raw material transportation, mixing, puffing, drying, and packaging. Flexible screw conveyor for extruded feed is mainly used to transport extruded feed to prevent feed particles from being squeezed or broken during transportation.

2. Automatic feeding system for farms

In aquaculture farms or livestock and poultry farms, the automated transportation and feeding of feed is the key to improving production efficiency. The use of a flexible screw conveyor for extruded feed can achieve precise transportation and quantitative feeding, improve feed utilization, and reduce labor costs.

3. Pet food production line

Pet food is usually made by high-temperature puffing process, the particles are brittle, and different types of pet food require precise ingredients and packaging. The conveying link of the flexible screw conveyor for extruded feed needs to minimize crushing to maintain the appearance and nutritional integrity of the product.

4. Storage and transportation of feed processing enterprises

After processing, extruded feed needs to be stored in silos or transported to customer sites. The conveying equipment must ensure the integrity of feed particles to avoid crushing or pulverization. Flexible screw conveyor for extruded feed is very suitable for short-distance storage and loading transportation due to its characteristics of buffering, low-speed operation and no extrusion.

If you need to purchase or learn more about the flexible screw conveyor for extruded feed, you can contact Dahan Machinery Manufacturer, which can provide customized solutions and detailed technical parameters according to your specific needs.