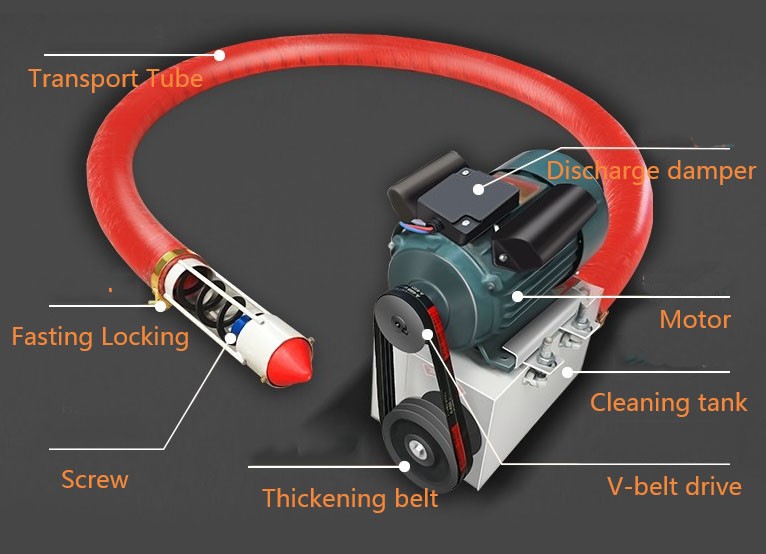

Flexible screw conveyor for plastic particles

Monday September-30 2024 11:01:50

Flexible screw conveyor for plastic particles is a conveying equipment specially used for conveying plastic granules. It combines the conveying efficiency of traditional screw conveyors and the flexibility of flexible conveyors, and has been widely used in the plastic processing industry.

1.Working principle of flexible screw conveyor for plastic particles

The working principle of the flexible screw conveyor for plastic pellets is basically similar to that of the traditional screw conveyor, but it has a flexible conveying pipe, which allows it to adapt to complex conveying paths and layout requirements. The following is the working principle of the flexible screw conveyor for plastic pellets:

Material entry: Plastic pellets enter from one end of the hose.

Screw propulsion: The spiral blades rotate, lifting the plastic pellets and pushing them forward.

Material conveying: The plastic pellets move forward along the hose under the push of the spiral blades.

Material discharge: The plastic pellets reach the other end of the hose and are discharged.

2.Application scenarios of flexible screw conveyor for plastic particles

Plastic granule flexible screw conveyors are widely used in many industries, especially in scenarios where plastic granules or granular materials need to be conveyed. The following are some common application scenarios of plastic granule flexible screw conveyors:

Plastic processing industry: In the plastic processing process, plastic granule flexible screw conveyors are often used to convey raw plastic granules from storage bins to production equipment such as injection molding machines and extruders to achieve automatic conveying and feeding.

Food processing industry: In food processing production lines, plastic granule flexible screw conveyors can be used to convey granular food raw materials such as grains, rice flour, powdered sugar, etc., as well as finished granular foods such as candy, puffed foods, etc.

Chemical industry: In the chemical production process, plastic granule flexible screw conveyors can be used to convey chemical raw material granules such as pigments, powders, granular chemicals, etc., as well as finished granular products.

Building materials industry: In the production of building materials, plastic granule flexible screw conveyors can be used to convey granular building materials such as cement, sand, stone, etc., as well as products such as precast concrete blocks.

Agricultural field: In agricultural production, plastic granule flexible screw conveyors can be used to convey granular feed, seeds and other agricultural raw materials to improve production efficiency.

3.Advantages of Plastic Granule Flexible Screw Conveyor

Compared with traditional fixed screw conveyors, flexible screw conveyors for plastic pellets have some obvious advantages, which make them more competitive in specific application scenarios. Here are some advantages of flexible screw conveyors for plastic pellets:

Strong adaptability: The flexible conveying pipeline design enables the flexible screw conveyor for plastic pellets to adapt to complex conveying paths and layout requirements, and can realize tortuous and curved conveying routes in limited space.

Reduce blockage and jamming: Flexible conveying pipelines can avoid blockage or jamming of materials during transportation, maintain continuous transportation of materials, and improve production efficiency.

Reduce maintenance costs: Flexible conveying pipelines reduce friction and wear during transportation, reduce equipment maintenance costs, and extend the service life of equipment.

Increase production efficiency: Flexible screw conveyors for plastic pellets can realize automatic transportation, improve the transportation efficiency of the production line, reduce manual operation, and reduce production costs.

Applicable to a variety of materials: This type of conveyor can convey plastic pellets of different particle sizes and properties, as well as other granular materials, and has strong versatility.

4.Selection suggestions for flexible screw conveyors for plastic particles

Choosing the right flexible screw conveyor for plastic pellets requires considering multiple factors to ensure that the equipment can meet your production needs and improve efficiency. Here are some suggestions to help you make the selection:

Material properties: First, consider the properties of the plastic pellets to be conveyed, including particle size, density, humidity, etc. Different plastic pellets may require different types of conveyors to ensure smooth conveying and avoid blockage.

Conveying distance and height: Consider the distance and height of the conveying to determine the required conveyor length and power. Make sure that the selected conveyor can cover the required conveying range.

Conveying capacity: Select the appropriate model and specification of the flexible screw conveyor for plastic pellets according to the actual conveying capacity requirements to ensure that it can meet production needs.

Working environment: Consider the characteristics of the working environment, such as temperature, humidity, corrosiveness, etc., and choose wear-resistant and corrosion-resistant conveyor materials and suitable drive methods.

Conveying path and layout: Consider the layout of the production site and the complexity of the conveying path, and choose a flexible screw conveyor with a flexible conveying pipe to adapt to different conveying path requirements.

In short, the plastic granule flexible screw conveyor has been widely used in the plastic processing industry due to its flexibility, high efficiency, sealing and other characteristics. It can not only improve production efficiency, but also improve the production environment and reduce production costs.