Flexible screw conveyor for sand

Thursday October-10 2024 10:43:33

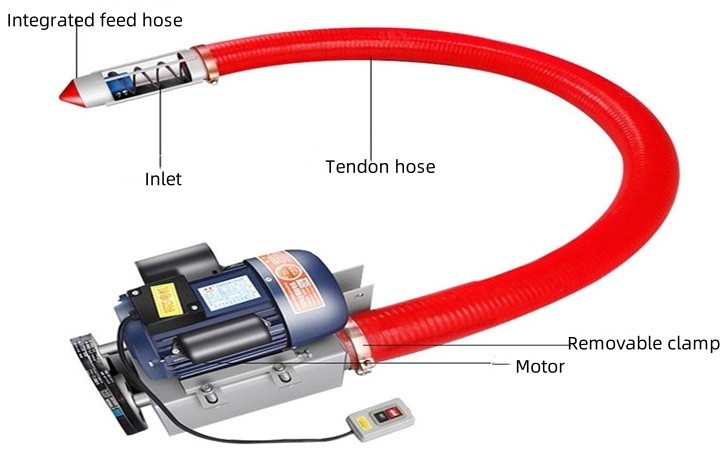

Flexible screw conveyor for sand is a kind of equipment used to transport granular materials such as sand and gravel. It is usually composed of spiral blades, spiral shaft, outer tube, feed port, discharge port, transmission device and other parts.

1.Working principle of sand and gravel flexible screw conveyor

Flexible screw conveyor for sand is a device that transports materials along the pipeline through spiral blades. Its working principle is as follows:

Material loading: First, load the sand and gravel to be transported into the feed port of the conveyor.

Spiral blade transmission: The conveyor is equipped with spiral blades. When the conveyor starts, the motor drives the spiral blades to rotate, and the rotation of the spiral blades pushes the materials along the pipeline.

Material conveying: The material moves forward along the pipeline under the push of the spiral blades, forming a continuous conveying flow.

Flexible conveying: Since the sand and gravel flexible screw conveyor adopts flexible spiral blades and pipeline design, it can adapt to curved conveying lines and realize curved conveying.

Material unloading: When the material is transported to the destination, the material can be unloaded to the designated location through the discharge port of the conveyor.

Continuous cycle: The spiral blades of the conveyor rotate continuously, continuously transporting the material from the feed port to the discharge port, realizing a continuous material conveying process.

2.Application scenarios of sand and gravel flexible screw conveyor

Sand and gravel flexible screw conveyors are widely used in various industrial fields, mainly including the following aspects:

Construction industry: used for the transportation of construction materials such as sand, gravel, cement, etc., which can transport raw materials from warehouses to production lines, or transport finished products to packaging areas.

Mining industry: used for the transportation of materials such as ore, coal, and mineral sand, which can transport raw materials from mines to processing plants, or transport finished products to warehouses or loading areas.

Chemical industry: used for the transportation of chemical raw materials and granular chemical products, which can realize material transportation between production lines and ensure the continuity of the production process.

Metallurgical industry: used for the transportation of metal ores, slag and other materials, which can transport raw materials to smelting equipment, or transport finished products to warehouses or transportation areas.

3.Advantages of sand and gravel flexible screw conveyor

Compared with traditional rigid screw conveyors, sand and gravel flexible screw conveyors have many advantages, including but not limited to the following:

Flexible conveying: Sand and gravel flexible screw conveyors use flexible spiral blades and pipes, which can adapt to complex conveying line layouts, realize curved conveying, and save space.

Strong adaptability: It can be used for the conveying of various granular materials, such as sand, gravel, cement, etc., and is widely used in construction, mining, chemical and other industries.

Strong conveying capacity: It has a large conveying capacity and can meet the material conveying needs of different production lines.

Simple structure and convenient maintenance: The equipment structure is relatively simple, and maintenance and cleaning are relatively easy, which reduces the maintenance cost of the equipment.

Good stability: Stable operation, materials are not prone to blockage or leakage during transportation, ensuring the stability of the production process.

4.Selection suggestions for sand and gravel flexible screw conveyor

When choosing a sand and gravel flexible screw conveyor, here are some suggestions to ensure that the selection is appropriate and meets actual production needs:

Material characteristics: Consider the properties of the sand and gravel materials to be transported, including particle size, density, humidity, etc., to ensure that the selected equipment can effectively transport these materials.

Conveying distance and conveying volume: Determine the amount of sand and gravel materials to be transported and the conveying distance in order to select a sand and gravel flexible screw conveyor with sufficient conveying capacity.

Working environment: Consider the environmental conditions in which the equipment will operate, including factors such as temperature, humidity, and corrosiveness, and select durable and corrosion-resistant materials and coatings.

Safety: Ensure that the selected sand and gravel flexible screw conveyor meets relevant safety standards to ensure the safety of the production process.

In short, the sand and gravel flexible screw conveyor has the characteristics of wear resistance and good sealing. It is particularly suitable for conveying abrasive, corrosive or granular materials in the conveying pipeline. It has reliable application prospects in warehouses, construction, chemical industry and other industries.