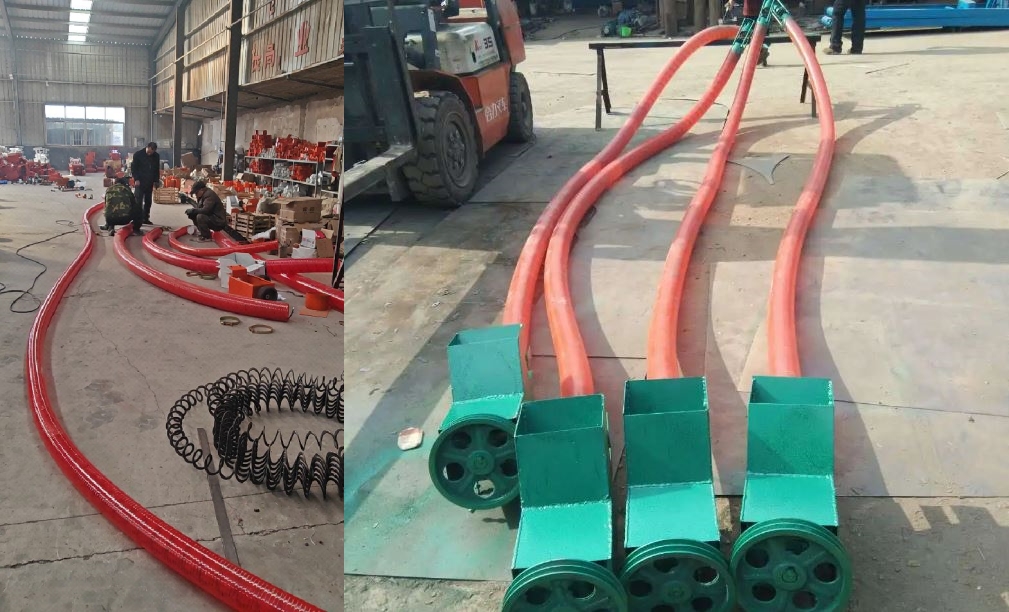

Flexible screw conveyor for sawdust

Sunday September-29 2024 10:05:06

Flexible screw conveyor for sawdust is a kind of equipment specially used for conveying sawdust and other powdery or granular materials. It uses flexible spiral blades to rotate in the tubular conveyor to transport the materials along the pipeline to the designated location.

1.Working principle of sawdust flexible screw conveyor

The working principle of the flexible screw conveyor for sawdust is as follows:

Material feeding: Sawdust enters the spiral part of the screw conveyor from the feed port.

Screw conveying: The spiral inside the screw conveyor rotates, pushing the sawdust to move along the pipe direction. The rotation of the spiral creates a thrust that pushes the sawdust forward.

Flexible pipe: During the conveying process, the flexible pipe allows the conveyor to bend and adapt to different layout requirements. This flexible design allows the conveyor to bend in the required direction to adapt to the requirements of the working environment.

Material discharge: Finally, the sawdust is discharged through the discharge port of the conveyor, completing the conveying process.

2.Application scenarios of sawdust flexible screw conveyor

Flexible screw conveyor for sawdust has a wide range of application scenarios in the woodworking industry and other fields that need to convey granular materials such as sawdust, including but not limited to the following aspects:

Woodworking industry: During the woodworking process, a large amount of granular materials such as sawdust and wood chips are generated. Sawdust flexible screw conveyor can be used to transport these materials from the processing site to storage equipment or processing equipment to improve production efficiency.

Biomass energy field: Biomass pellets are a common biomass energy raw material, such as wood chip pellets, sawdust pellets, etc. Sawdust flexible screw conveyor can be used to transport biomass pellets from the production line to combustion equipment or storage equipment for energy production.

Wood processing plant: Wood processing plants usually need to handle a large amount of wood chips and sawdust. Sawdust flexible screw conveyor can help transport these materials from processing equipment to storage areas or the next production link.

Building materials industry: When producing building materials, such as fiberboard, particle board, etc., it is often necessary to transport raw materials such as sawdust. Sawdust flexible screw conveyor can be used to transport these granular raw materials to ensure the continuity of the production line.

3.Advantages of sawdust flexible screw conveyor

Sawdust flexible screw conveyor has the following advantages:

Flexible conveying: The conveying pipeline can be bent arbitrarily, adapting to various complex conveying environments without space restrictions.

Good sealing: There is no dust leakage during the conveying process, which meets environmental protection requirements and reduces pollution to the environment.

Long conveying distance: The conveying distance is not limited and can be customized according to actual needs to meet the needs of long-distance material transportation.

Large conveying angle: The conveying pipeline can be bent arbitrarily to adapt to various complex conveying environments and realize multi-angle conveying.

Bearingless design: During the entire conveying process, the spiral blade is the only moving part, without bearings and other wearing parts, which greatly reduces maintenance costs.

Strong adaptability: Suitable for conveying various sawdust, wood chips, dust and other materials, with a wide range of adaptability.

High reliability: Simple structure, low failure rate, stable operation.

High efficiency: Fast conveying speed, high efficiency, can meet the production needs of high output.

4.Selection suggestions for sawdust flexible screw conveyor

When choosing a suitable sawdust flexible screw conveyor, you can consider the following points as selection suggestions:

Processing capacity: First, consider the amount of sawdust that your production line needs to process, select the appropriate processing capacity, and ensure that the conveyor can meet production needs.

Conveying distance and height: Consider the conveying distance and height to ensure that the selected flexible screw conveyor can cover the required conveying range.

Conveying angle and bending: According to the actual layout requirements, select a flexible screw conveyor that can meet the conveying angle and bending requirements to ensure that it is suitable for the production line layout.

Material characteristics: Consider the characteristics of the conveyed sawdust or other granular materials, such as particle size, humidity, etc., and select a suitable conveyor model to ensure a stable conveying effect.

Environmental requirements: Consider the characteristics of the working environment, such as temperature, humidity, etc., and select a flexible screw conveyor with good durability and strong adaptability.

In short, sawdust flexible screw conveyor is an efficient, reliable and environmentally friendly material conveying equipment, which is widely used in various industries. If you need to convey powdery or granular materials such as sawdust, sawdust flexible screw conveyor is a good choice.