Flexible screw conveyor for wood chips

Tuesday October-08 2024 15:43:45

Flexible screw conveyor for wood chips is a mechanical device specially used for conveying wood chips. It uses flexible spiral blades to rotate in a tubular conveyor to convey wood chips from one location to another. This conveyor is widely used in wood processing, paper making and other industries due to its flexible structure, strong adaptability and high conveying efficiency.

1.Working principle of wood chip flexible screw conveyor

The working principle of the wood chip flexible screw conveyor is as follows:

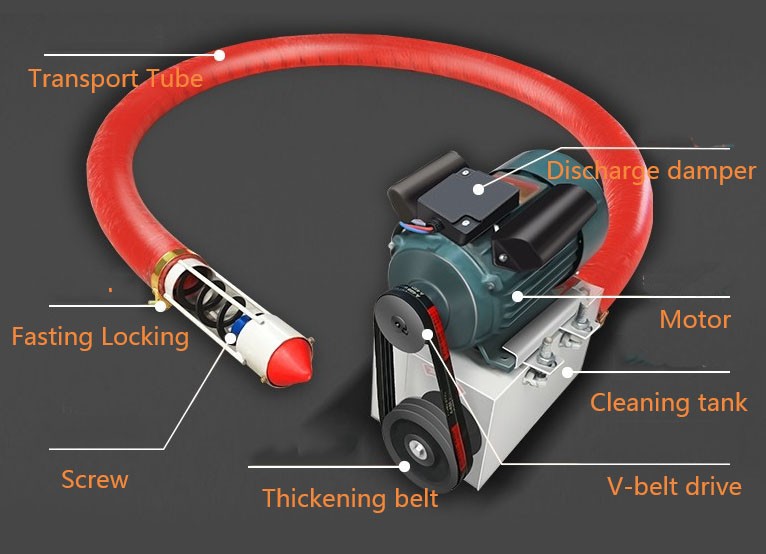

Feed port: Granular materials such as wood chips or sawdust enter the flexible screw conveyor through the feed port.

Screw conveyor: The conveyor usually contains a screw inside, which generates a driving force by rotating to push the material forward along the spiral line direction of the screw.

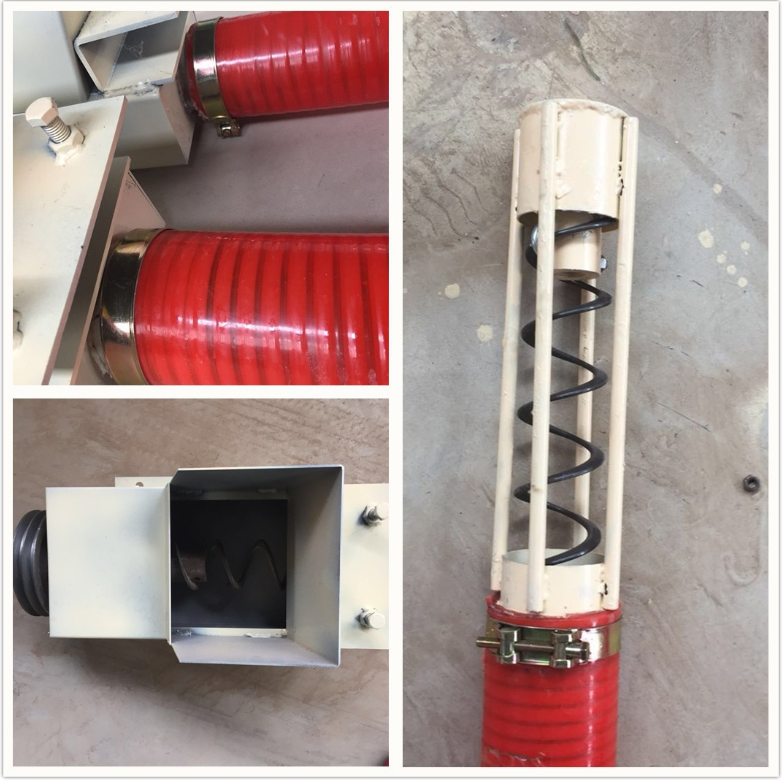

Flexible spiral tube: The flexible spiral tube is a key component of the conveyor. It can bend in the vertical and horizontal directions, allowing the conveyor to convey materials along an irregular path.

Conveying materials: The rotation of the spiral pushes the material into the flexible spiral tube, and the material is conveyed to the desired location along the path of the spiral tube.

Discharge port: After being conveyed to the destination, the material is discharged through the discharge port.

Control system: The flexible screw conveyor is usually equipped with a control system that can adjust the speed and conveying direction of the screw to ensure accurate material delivery.

2.Application scenarios of wood chip flexible screw conveyor

Flexible screw conveyor for wood chips has a wide range of applications in many industries and scenarios, including but not limited to the following areas:

Woodworking industry: Wood chip flexible screw conveyor is often used in the woodworking industry for conveying and processing wood granular materials such as wood chips, wood chips, and wood chips. It can transport raw materials from one process to another to improve production efficiency.

Biomass energy industry: In biomass pellet production lines, wood chip flexible screw conveyors are often used for conveying and processing granular biomass raw materials, such as wood chip pellets, straw pellets, etc.

Food processing industry: In the process of food processing, wood chip flexible screw conveyors can be used to convey grains, powders, granular food raw materials, etc., such as in grain processing plants or food processing plants.

Paper making industry: Wood chip flexible screw conveyors can be used to convey raw materials or semi-finished products such as wood chips and pulp in the paper making industry to help improve production efficiency.

3.Advantages of Wood Chip Flexible Screw Conveyor

The wood chip flexible screw conveyor has many advantages that make it widely used in many industries and applications. Here are some of the main advantages:

Wide applicability: The wood chip flexible screw conveyor is suitable for the conveying of a variety of granular materials, such as wood chips, sawdust, granular food raw materials, biomass pellets, etc., and has strong versatility.

Flexibility: Due to the flexible screw conveying method, the wood chip flexible screw conveyor can adapt to different conveying angles and curves, and is suitable for complex conveying layouts.

High conveying efficiency: The wood chip flexible screw conveyor has a reasonable design and high conveying efficiency. It can convey materials quickly and continuously, and improve production efficiency.

Low maintenance cost: The wood chip flexible screw conveyor has a simple structure, relatively low maintenance cost, and is easy to maintain and clean.

Reduced material loss: The wood chip flexible screw conveyor has less material loss during the conveying process, which helps to reduce production costs.

4.Selection suggestions for wood chip flexible screw conveyor

The following factors should be considered when selecting a suitable wood chip flexible screw conveyor:

Material properties: Consider the density, particle size, humidity and other properties of the wood chips or sawdust being conveyed. Different material properties will affect the selection of the conveyor. For example, a specially designed conveyor may be required for materials with high humidity.

Conveying distance and height: Determine the distance and height required for conveying to ensure that the selected conveyor can meet the actual needs.

Working environment: Consider the working environment where the conveyor will be installed, including factors such as temperature, humidity, and dust. Choose corrosion-resistant and wear-resistant materials to adapt to harsh working environments.

Production capacity requirements: Select appropriate conveyor models and specifications according to the production capacity requirements of the production line to ensure that the conveyor can meet production needs.

Maintenance and cleaning requirements: Consider the difficulty of maintenance and cleaning of the equipment, and choose a design that is easy to maintain and clean to ensure long-term stable operation of the equipment.

In short, compared with traditional screw conveyors, flexible screw conveyors have higher flexibility, adaptability and reliability, so they have been widely used in modern industrial production.