Fly ash bucket elevator

Thursday February-13 2025 15:36:36

Fly ash bucket elevator is a kind of vertical or inclined conveying equipment, specially used for conveying fly ash and other powdery or granular materials, and is widely used in power, building materials, chemical industry and other industries. It lifts fly ash from low to high through the hopper installed on the chain or belt, and is suitable for continuous conveying of powdery, granular or small pieces of materials. It has the characteristics of simple structure, reliable operation and large conveying capacity.

Video of fly ash bucket elevator

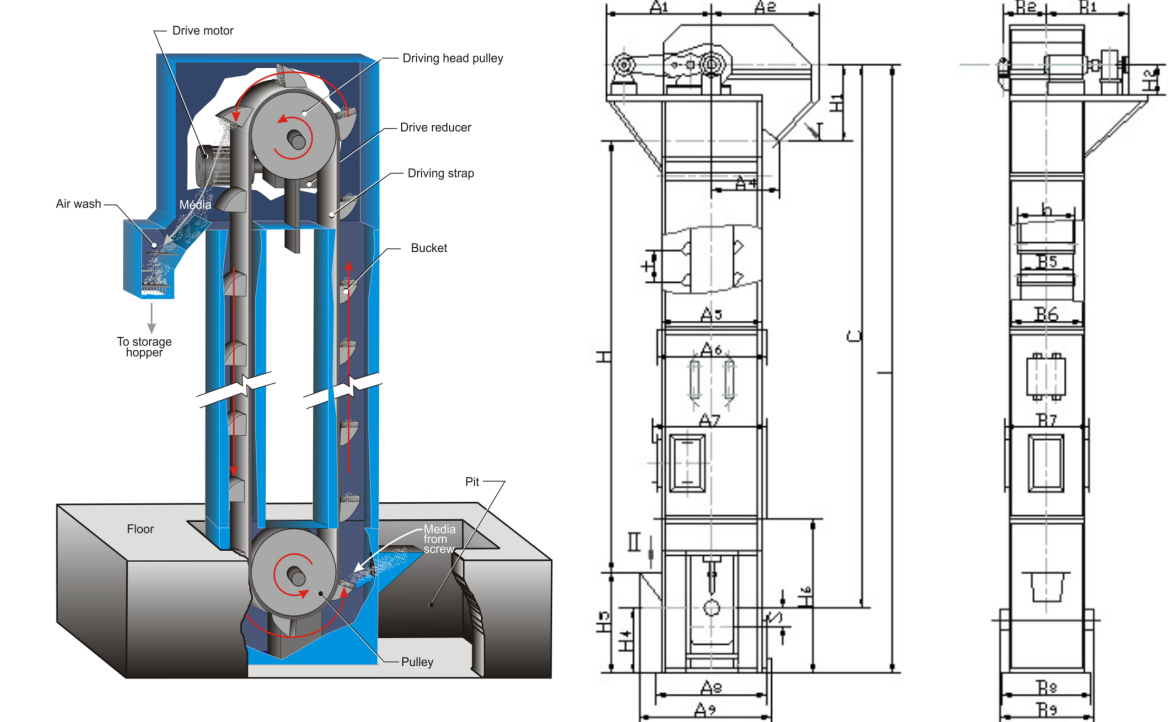

How does the fly ash bucket elevator work?

Fly ash is transported from the feed port to the discharge port by a bucket conveyor chain. The bucket conveyor chain runs along the upper and lower wheel sets of the elevator, and the bucket is fixed on the chain. When the chain rotates, the bucket elevator will lift the fly ash from the feed port to the required height, and then release the material from the discharge port by gravity. In this way, the fly ash is continuously lifted from the bottom to the top.

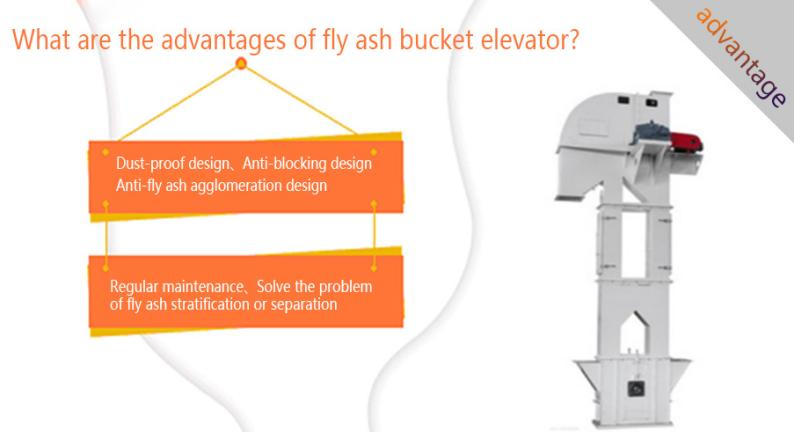

What are the advantages of fly ash bucket elevator?

1. Dust-proof design: Bucket elevators can take some dust-proof design measures, such as installing closed covers, water spraying dust suppression systems, etc., to reduce the impact of dust on the environment and operators.

2. Anti-fly ash agglomeration design: Fly ash is prone to agglomeration during transportation, affecting transportation efficiency. Bucket elevators can be designed with appropriate bucket shapes and bucket distances to reduce the possibility of fly ash agglomeration.

3. Anti-blocking design: To prevent bucket elevators from blocking during operation, regular cleaning, setting up blocking detectors, and increasing discharge ports can be taken to ensure smooth material transportation.

4. Regular maintenance: Regular maintenance of bucket elevators is the key to ensuring the normal operation of equipment. Including operations such as lubricating chains, checking transmission devices, and cleaning blocked materials, which help reduce the occurrence of faults.

5. Solve the problem of fly ash stratification or separation: Fly ash may be stratified or separated during transportation due to different particle sizes or densities. By controlling the feeding speed and method, ensure that fly ash enters the hopper evenly. The equipment runs smoothly to avoid severe vibration that may cause material stratification.

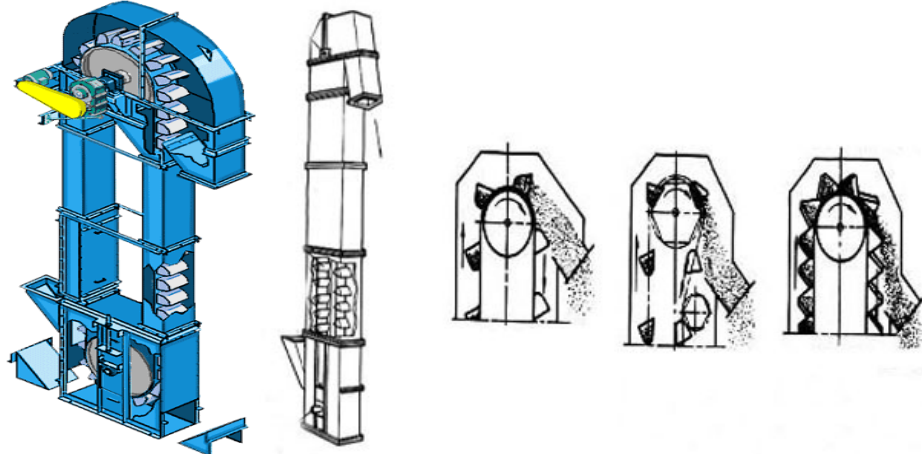

Structure of fly ash bucket elevator

Fly ash bucket elevator mainly consists of the following parts:

Bucket: used to carry fly ash, usually made of metal or plastic, and moves up and down with the chain.

Chain or belt: used to connect and drive the hopper, convert the rotational motion of the motor into the up and down motion of the chain, and drive the hopper to lift.

Drive device: including motor, reducer and transmission device to provide power. Usually an electric motor is used to provide power for the elevator.

Head and tail: The head is the discharge end and the tail is the feed end.

Casing: closed structure, surrounds the entire elevator to prevent dust spillage, material splashing and environmental pollution.

Tensioning device: used to adjust the tightness of the chain or belt, maintain the tension of the chain, and ensure smooth operation.

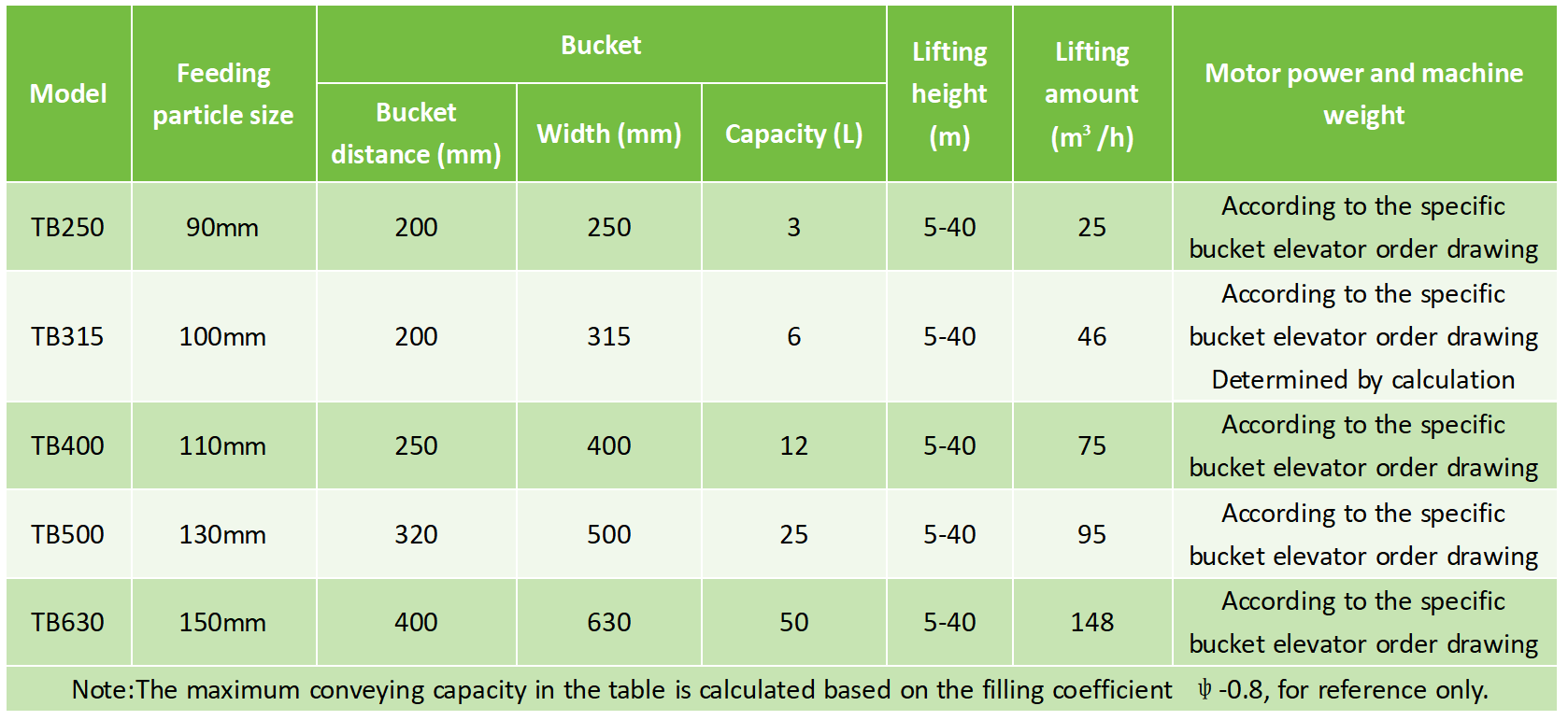

Technical parameters of fly ash bucket elevator

Application scenarios of fly ash bucket elevator

Power plant boiler ash conveying system: The fly ash generated by the boiler is conveyed to the ash storage yard or processing equipment. The fly ash bucket elevator lifts the ash at the bottom of the boiler to the high-level ash bin, and then transports it to the ash yard through the conveyor.

Cement production line raw material conveying system: The fly ash bucket elevator lifts the fly ash from the storage bin to the raw material mill, and mixes it with other raw materials to make raw materials. The fly ash is transported to the production line for the production of cement and other building materials.

Fly ash brick production line: The fly ash bucket elevator conveys the fly ash to the brick making machine, and after pressing and molding, it is made into various types of bricks.

Fly ash bucket elevator manufacturers

As a reliable conveying equipment, the fly ash bucket elevator plays an important role in the conveying process of fly ash. By selecting a suitable bucket elevator and taking corresponding measures, the problems encountered in the fly ash conveying process can be effectively solved, the conveying efficiency can be improved, and the working environment can be improved.