Food grade plastic granule bucket elevator

Wednesday February-26 2025 17:06:03

What is food grade plastic bucket elevator?

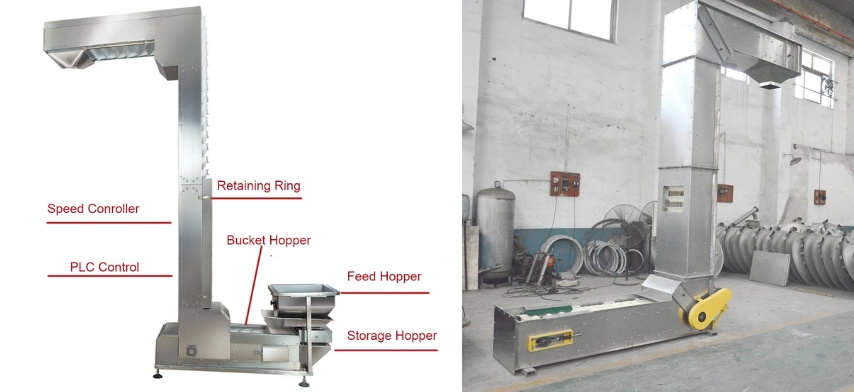

Food grade plastic granule bucket elevator is a material vertical conveying equipment designed specifically for the food industry, used for vertically conveying granular food grade plastic granules. It uses a hopper made of food grade plastic to ensure that the material is not contaminated during transportation and meets food hygiene and safety standards. This type of equipment is commonly used in the food processing industry and other related industries to transport raw materials or finished particles from one location to another, such as from the ground to the production line or storage bin above.

Food grade plastic bucket elevator video

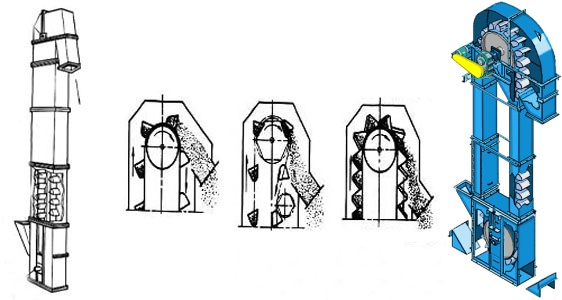

How does the food grade plastic bucket elevator work?

Food grade plastic granule bucket elevator is equipped with a hopper above the two ring chains. The hopper scoops up plastic pellets from the storage below. When the motor drives the chain to rotate, the plastic pellets are lifted to the top along with the conveyor chain, and then the plastic pellets are lifted and transported to the designated location for unloading. Its running track is first horizontal conveying, then vertical lifting, and then horizontal conveying.

What are food grade plastic granule bucket elevators made of?

Food grade plastic granule bucket elevator is mainly composed of a hopper, transmission components, driving device, casing, feed and discharge ports, tensioning device, fasteners, etc. Food grade plastic is the core to ensure that the materials are not contaminated, and other components are selected according to their functions and environment.

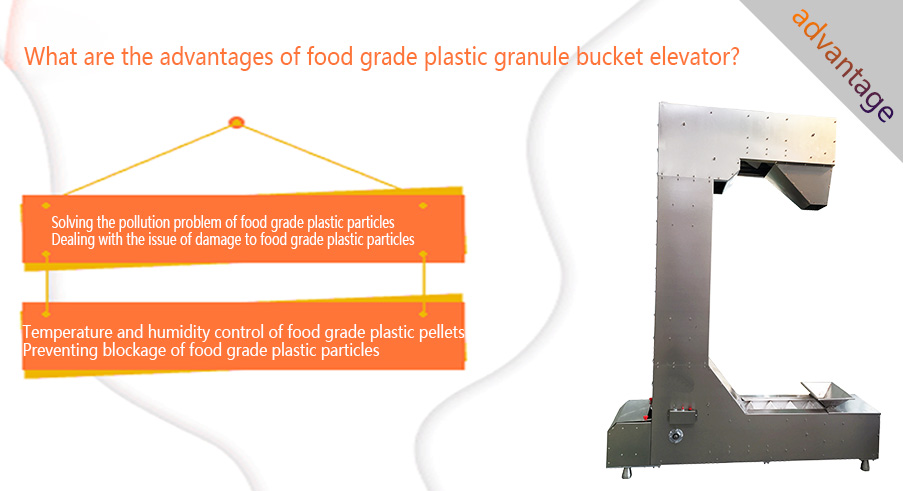

What are the advantages of food grade plastic granule bucket elevator?

1. Solving the pollution problem of food grade plastic particles: During the transportation process, plastic particles may be contaminated by dust, bacteria, foreign objects, etc., affecting product quality and food safety. Food grade plastic granule bucket elevator adopts a hopper made of food grade plastic, ensuring that the parts in contact with the material and equipment are non-toxic, odorless, corrosion-resistant, and comply with food hygiene and safety standards.

2. Dealing with the issue of damage to food grade plastic particles: During transportation, plastic particles may be damaged due to collisions, friction, and other reasons, affecting the appearance and quality of the product. The food grade plastic granule bucket elevator operates smoothly and reliably, reducing collisions and friction of materials during transportation.

3. Temperature and humidity control of food grade plastic pellets: Food grade plastic pellet bucket elevator can be installed in an environment with controllable temperature and humidity to avoid moisture or overheating of the pellets, and can be continuously and stably transported to ensure production efficiency.

4. Preventing blockage of food grade plastic particles: The design of the feeding port ensures that plastic particles enter the hopper evenly and stably, avoiding blockage caused by excessive or uneven feeding. The size and shape of the discharge port have been carefully designed to ensure smooth discharge of plastic particles and prevent accumulation at the discharge port.

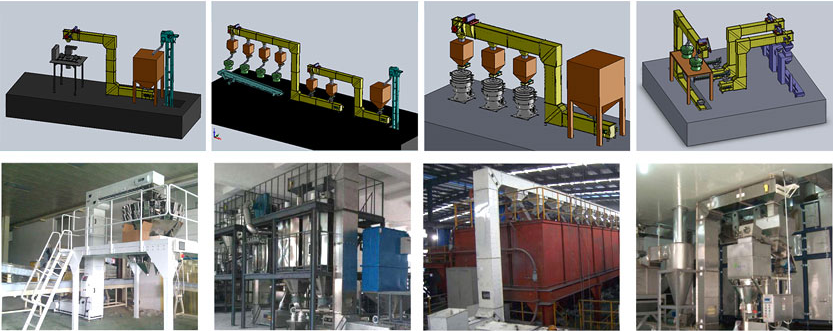

Application of food grade plastic granule bucket elevator

1. Food processing production line: Food grade plastic granule bucket elevator is commonly used in food processing production lines to transport food raw materials (such as grains, beans, sugar powder, etc.) from the ground to the upper layer or different process sections for subsequent processing.

2. Packaging line: In the food packaging production line, the food grade plastic granule bucket elevator can be used to vertically transport packaging materials (such as plastic granules, packaging bags, etc.) to the feeding port of the packaging machinery.

3. Food Storage: Used in food storage management, food grade plastic granule bucket elevator can transport food raw materials from the ground to storage warehouses or different levels of warehouses for convenient storage and management.

4. Food mixing and stirring: In the food production process, the food grade plastic particle bucket elevator can be used to vertically transport different food ingredients to the mixing and stirring equipment, achieving the mixing and uniformity of food ingredients.

How do you clean food grade plastic granule bucket elevator?

1. Preparation before cleaning: Firstly, ensure that the hoist has completely stopped running and disconnect the power supply to prevent accidental start-up. Thoroughly empty all materials in the hopper and casing to avoid residue affecting the cleaning effect. Choose non-toxic, odorless, and non corrosive plastic cleaning agents.

2. Cleaning steps: Use a soft bristled brush or cloth to remove loose materials and dust from the hopper and casing of food grade plastic granule bucket elevator. Disassemble the hoppers one by one and thoroughly clean them with food grade cleaning agents and water. Pay attention to cleaning the corners and gaps of the hopper to avoid residue. Rinse thoroughly with clean water to ensure there are no residues of cleaning agents. Thoroughly rinse all components with clean water to ensure there are no residues of cleaning agents or disinfectants, and dry them with a clean cloth or let them air dry naturally.

3. Inspection after cleaning: Carefully inspect all components to ensure there is no residue or dirt, check if the transmission components are loose, if the fasteners are secure, reassemble the hopper and other disassembled components, turn on the power, conduct a trial run, and check if the equipment is working properly.

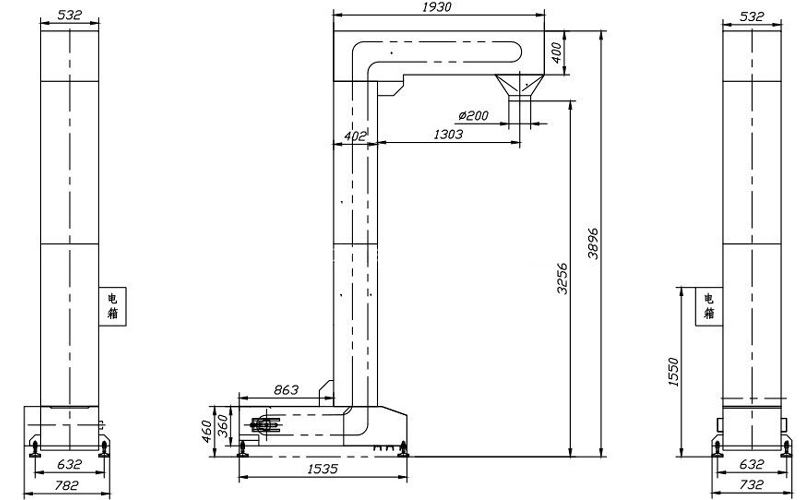

Technical Parameter of Food grade plastic granule bucket elevator

|

bucket volume |

1.8L |

3.6L |

6.5L |

|

bucket material |

pp |

ss304 |

ABS |

|

body material |

mild steel |

stainless steel |

--- |

|

NO.S of discharge port |

single |

muti-discharge port |

--- |

|

output |

4-6m3/h |

6.5-8m3/h |

5.5-12m3/h |

|

voltage(v) |

220v/240v/as you need |

380v/415v/440v/as you need |

as you need |

|

speed |

adjustable |

||

|

conveying capacity |

3-10m3/h |

||

Food grade plastic granule bucket elevator price

The price of food grade plastic pellet bucket elevator will be affected by various factors, including but not limited to the following:

1. Specifications and sizes: The price of food grade plastic pellet bucket elevators may vary depending on the specifications and sizes. Large and high-capacity equipment is usually more expensive.

2. Material: Food grade plastic pellet bucket elevators made from high-quality materials such as food grade plastic or stainless steel may be more expensive.

3. Market supply and demand situation: Market supply and demand situation can also have an impact on prices. In the case of oversupply, prices may decrease; When demand is strong, prices may rise.

Due to the influence of the above factors, the price range of food grade plastic pellet bucket elevators is very wide, generally ranging from several thousand US dollars to tens of thousands of yuan.

Food grade plastic granule bucket elevator supplier

Food grade plastic granule bucket elevators play an important role in the food processing industry, improving production efficiency and ensuring food safety and quality. When selecting and using equipment, it should be based on production needs, food safety standards, and equipment performance requirements.