Food-grade plastic pellet bucket elevator

Wednesday March-05 2025 17:05:08

Food-grade plastic pellet bucket elevator is a material conveying equipment specially used for vertically conveying food grade plastic pellets. It can safely and hygienically lift plastic pellets and other materials vertically to a specified height. Its design complies with food hygiene standards to ensure that the materials are not contaminated during the conveying process. This elevator is widely used in food packaging, plastic product production, chemical industry and other fields.

Food-grade plastic pellet bucket elevator video

What is the function of food-grade plastic pellet bucket elevator?

1. Realize vertical transportation of materials: Food-grade plastic pellet bucket elevator can lift plastic pellets from low to high to realize vertical transportation of materials.

2. Adapt to different production needs: Food-grade plastic pellet bucket elevator can be customized according to the needs of different production lines to meet the transportation requirements of different specifications, capacities and heights, and has strong adaptability.

3. Reduce loss and waste: Food-grade plastic pellet bucket elevator can stably transport pellets, reduce the loss and waste of pellets during transportation, and help reduce production costs.

4. Improve material handling efficiency: Food-grade plastic pellet bucket elevator can help processing plants or storage and logistics centers quickly and efficiently process food pellets and improve material handling efficiency.

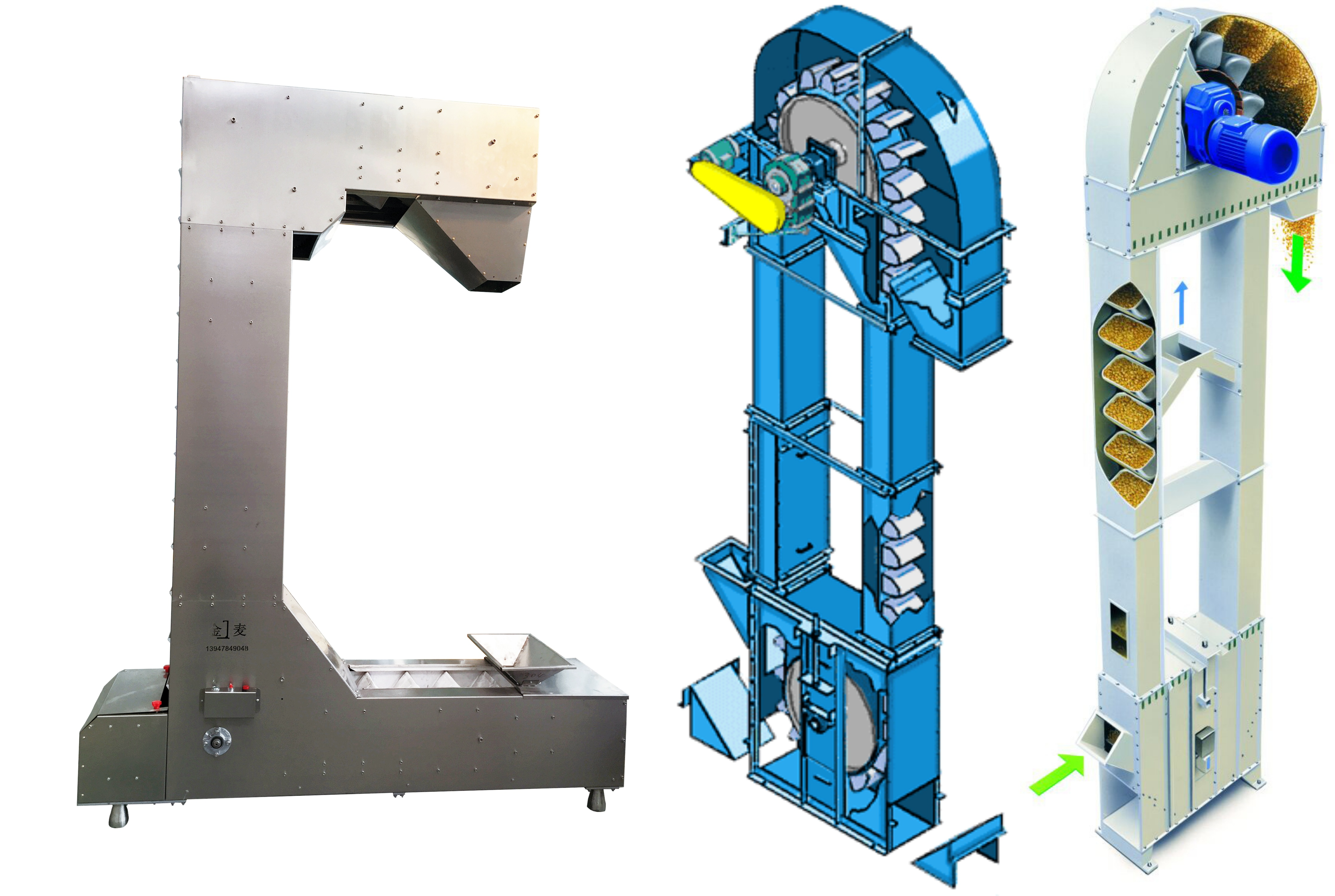

What is the working principle of food-grade plastic pellet bucket elevator?

The working principle of food-grade plastic pellet bucket elevator is based on bucket conveying:

1. Loading: Plastic pellets enter the bottom of the elevator from the feed port and are scooped up by the bucket.

2. Lifting: The bucket rises vertically with the traction member (such as a belt or chain) to lift the material to a specified height.

3. Unloading: At the top, the bucket flips over and discharges the plastic pellets through the discharge port.

4. Cycle: The empty bucket returns to the bottom to continue the next loading and lifting.

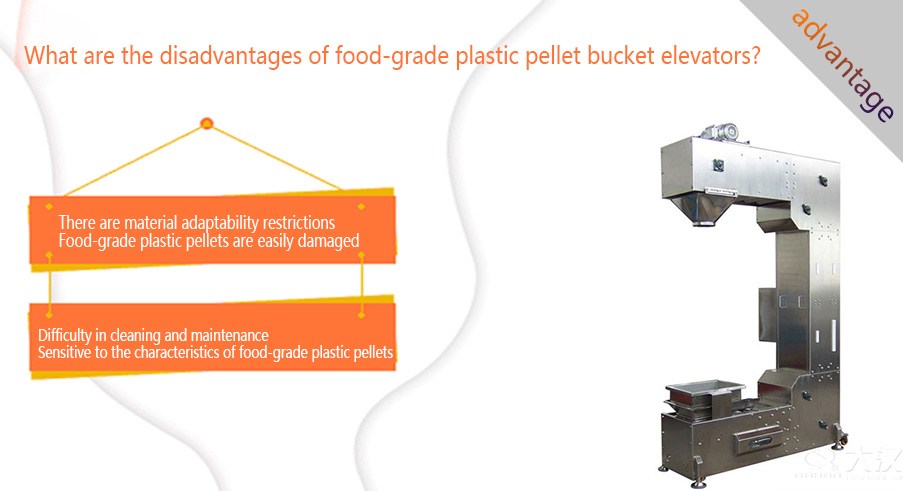

What are the disadvantages of food-grade plastic pellet bucket elevators?

1. There are material adaptability restrictions: Food-grade plastic pellet bucket elevators have certain restrictions on material adaptability. For plastic pellets with high viscosity or high water content, problems such as adhesion and clogging are prone to occur, affecting the conveying efficiency.

2. Food-grade plastic pellets are easily damaged: During the lifting process, plastic pellets may be squeezed, rubbed, etc., resulting in damage or deformation, affecting product quality. This is particularly prominent for some brittle or fragile plastic pellets.

3. Difficulty in cleaning and maintenance: Although food-grade materials themselves have certain hygienic properties, the structure of food-grade plastic pellet bucket elevators is relatively complex, especially the connection between the hopper and the conveyor belt, which is easy to accumulate material residues and difficult to clean.

4. Sensitive to the characteristics of food-grade plastic pellets: For plastic pellets with high viscosity or high humidity, they are easy to adhere to the hopper or casing, affecting the conveying efficiency. For ultrafine particles (such as<1mm), there may be dust problems.

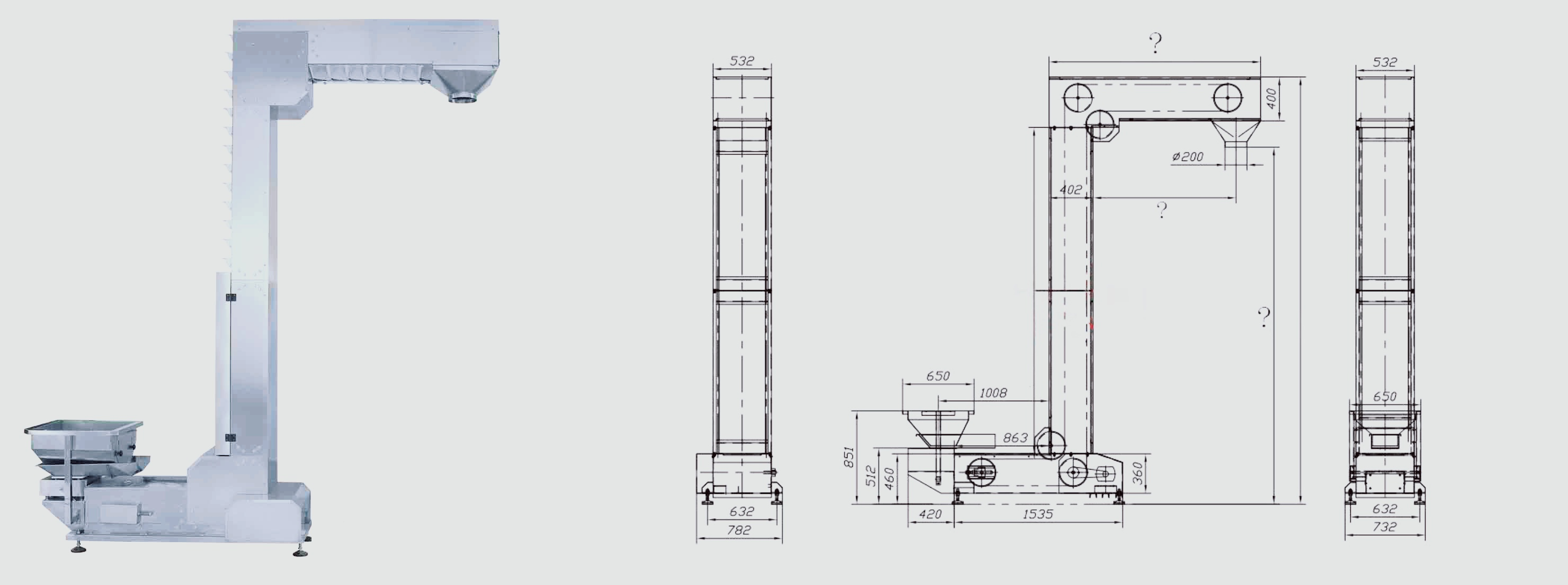

The structure of food-grade plastic pellet bucket elevator

The structure of the food grade plastic pellet bucket elevator The food grade plastic pellet bucket elevator is mainly composed of a frame, a hopper, a drive device, a chain or a belt, a tensioning device and a casing.

Application of food-grade plastic pellet bucket elevator

1. Food processing production line: Food-grade plastic pellet bucket elevator is used to convey food grade plastic particles, including plastic particle raw materials needed in food processing production line, such as material conveying in the production process of food packaging boxes, containers, etc.

2. Food grade plastic product production: Food-grade plastic pellet bucket elevator is used to convey food grade plastic particles, such as plastic particle raw materials needed in the production process of food grade plastic products, such as material conveying in the production process of tableware, containers, etc.

3. Food grade particle screening and sorting: used in food grade particle processing production line, such as material conveying and processing in the mixing, extrusion, molding and other processing processes of food grade plastic particles. Food-grade plastic pellet bucket elevator can be used to convey plastic particles of different particle sizes to the corresponding processing equipment.

4. Plastic packaged food additives: Some food additives (such as vitamins, pigments, etc.) are packaged in plastic containers. In the production process of these packaging containers, food-grade plastic pellet bucket elevator is used to convey plastic raw materials.

Food-grade plastic pellet bucket elevator is an efficient, hygienic and safe vertical conveying equipment. Through reasonable selection, operation and maintenance, it can significantly improve production efficiency and ensure product quality.