Function of cooling screw conveyor

Friday March-11 2022 09:45:46

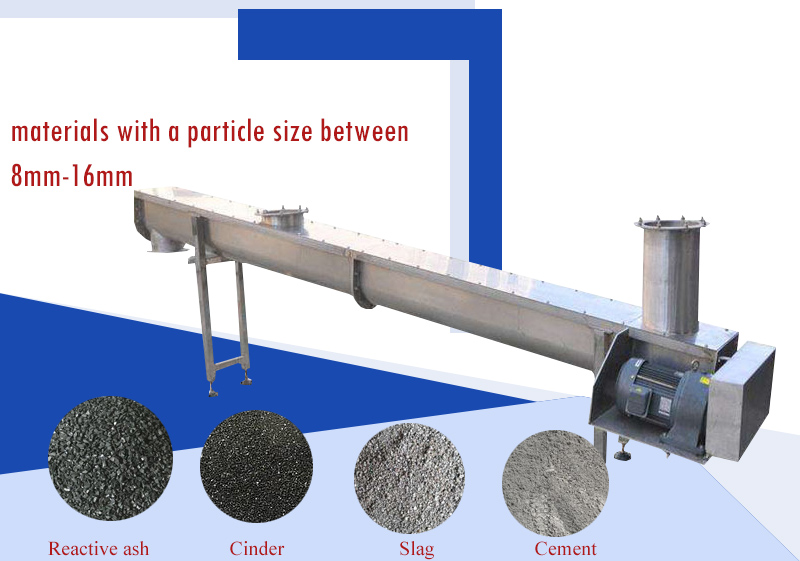

The cooling screw conveyor is used to transport high-temperature powder, small granular and other bulk materials in a closed tube body. The maximum temperature of the feeding material can reach 720 °C. The cooling water flowing in the spacer and the central spiral tube makes the discharge temperature reach 50 °C. , is a conveying equipment that integrates cooling and conveying. The following is an analysis of the main functions of the cooling screw conveyor:

1、Simultaneous transport and cooling

In addition to conveying materials, the cooling screw conveyor can also cool high-temperature materials. The machine is equipped with a cooling system inside and outside the machine, and the outer cylinder of circulating water is used to keep the water at a low temperature and reduce the heating degree of the machine. Can meet the individual needs of users. It is used to transport materials with high temperature above 1000°C cooled to a temperature compatible with downstream processes (usually less than 200°C).

2、Can transport a variety of materials

The cooling screw conveyor can transport materials with high hardness such as metal pellets, materials with a particle size between 8mm-16mm, and high-temperature materials. Such as: cement, cinder, slag, and materials with high heat.

3、high volume of transport

The body length of the cooling screw conveyor can reach 20 meters, the transportation volume is large, and the discharge volume per hour is 6 meters.

The above is an introduction to the role of the cooling screw conveyor. The cooling screw conveyor is mainly for conveying materials that need to be cooled, and the conveying effect is good.