Glass bead linear vibrating screen

Wednesday March-12 2025 12:39:38

Glass bead linear vibrating screen is a device specially used for screening and grading glass bead materials. Glass beads are a lightweight, spherical artificial material, usually made of silicate glass, with small particle size, low density, good wear resistance and other characteristics. It is widely used in reflective materials (such as road marking paint), sandblasting, filling materials and other fields.

Video of glass bead linear vibrating screen

Applicability of glass bead linear vibrating screen

1. Material characteristics:

① The particle size range of glass beads is generally between tens of microns and several millimeters (such as 20-850 microns), which belongs to fine particle materials.

② Low water content, usually dry, non-sticky, very suitable for linear vibrating screen screening.

③ Good fluidity, not easy to clog the screen during screening.

2. Purpose of screening:

① Grading: glass beads are divided into different specifications according to particle size (such as coarse and fine particles for reflective coatings).

② Impurity removal: remove impurities or irregular particles that may be mixed in the production process.

What is the working principle of glass bead linear vibrating screen?

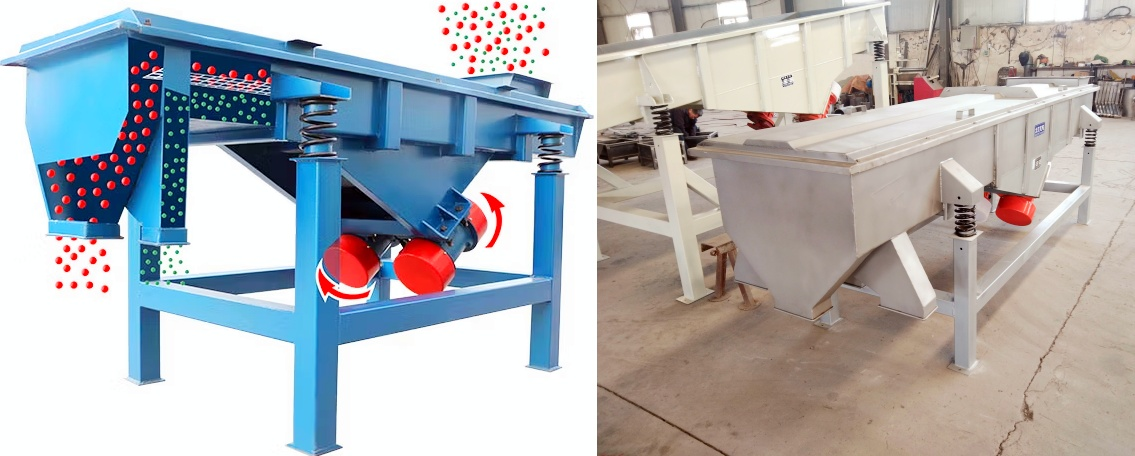

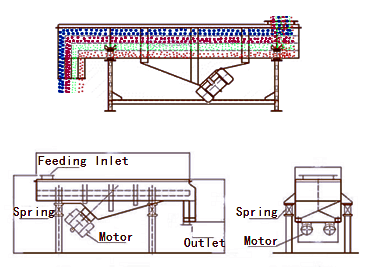

The glass bead linear vibrating screen is driven by a dual vibration motor. When the two vibration motors rotate synchronously and in reverse, the synthetic force generated by the excitation force causes the screen to vibrate linearly, thereby pushing the glass beads to jump forward along the screen surface. Beads of different particle sizes are separated layer by layer through the screen and finally discharged from different discharge ports.

What are the advantages of glass bead linear vibrating screen?

1. Improve grading accuracy: The glass bead linear vibrating screen can ensure that the beads stay on the screen surface for a moderate time to avoid mixing by adjusting the screen surface inclination angle (0°-15°) and the motor speed.

2. Balance the processing volume and efficiency: Choose a wide or long linear vibrating screen (such as 1.5m×4m) for the glass microbead linear vibrating screen to increase the single processing volume. Use a dual vibration motor to provide greater power while maintaining screening stability.

3. Deal with the problem of easy rolling and strong fluidity of glass microbeads: The surface of glass microbeads is smooth and easy to roll on the screen surface, resulting in uneven screening or material accumulation. The glass microbead linear vibrating screen makes the material jump on the screen surface in a straight line instead of rolling, thereby ensuring uniform distribution and efficient screening of the material.

4. Deal with the problem of glass microbeads being fragile: Glass microbeads are easily broken by vibration or collision during the screening process. The glass microbead linear vibrating screen adopts a low-amplitude, high-frequency vibration method to reduce the impact force on the glass microbeads and reduce the breakage rate.

Related parameters of vibrating screen for ore sand screening

Feed particle size: usually ≤150mm

Screen hole size: generally in the range of 3-50mm, can be Adjust according to demand

Screen material: Polyurethane screen is mostly used, which has the advantages of wear resistance, pressure resistance and long life

Number of layers: It can be designed as single layer or multi-layer to achieve sorting of various specifications

Processing capacity: Depending on the model, the processing capacity can reach tens to hundreds of tons per hour, for example, some equipment can reach up to 250t/h.

Application of glass microbead linear vibrating screen

Reflective material manufacturing (such as road marking paint): Glass microbeads are the key reflective component in road marking paint. The glass microbead linear vibrating screen can screen out uniform particle size, remove particles that are too large or too small, and ensure consistent reflective effect.

Industrial sandblasting: Glass beads are used as sandblasting media for metal surface cleaning, deburring or matte treatment. The particle size is usually between 30-320 microns, and the particles are required to be uniform and free of impurities. Unqualified beads (oversized or broken particles) will cause uneven sandblasting or damage the workpiece.

Plastic and composite material filling: Glass beads are added to plastics, rubber or resin as lightweight fillers. The glass bead linear vibrating screen can screen out beads with a specific particle size range to avoid excessively large particles affecting material uniformity or excessively fine particles increasing costs.

Glass bead linear vibrating screen is an indispensable equipment in the production and use of glass beads, which can effectively improve product quality and production efficiency. If you have specific needs (such as the particle size range, production volume or industry use of glass beads), you can contact customer service to further optimize the selection or provide more detailed suggestions!