Grain Suction Machine for Fly Ash

Tuesday March-11 2025 16:48:13

Grain suction machine for fly ash was originally designed for the suction and delivery of materials such as grains and cereals, but in industrial scenarios, its principle can also be used to transport, absorb and process fine, dry powdered materials or granular materials such as fly ash. Fly ash is fine particles produced after coal combustion, usually used in concrete production, filling materials, roadbed materials and other fields.

Video of Grain Suction Machine for Fly Ash

Feasibility of Grain Suction Machine for Fly Ash

1. Fly ash characteristics: Fly ash is a fine powdery waste produced by coal-fired power plants, with small particle size (usually less than 0.075mm), good fluidity, but easy to raise dust.

2. Adaptability of Grain Suction Machine: Grain Suction Machine for Fly Ash mainly transports fly ash through negative pressure airflow, which is suitable for conveying powdery and granular materials.

How does grain suction machine for fly ash work?

Grain suction machine generates negative pressure through vacuum pump or fan, forms airflow in the pipeline, sucks fly ash from the suction port and transports it to the designated location (such as silo or collector). For fly ash, it relies on the negative pressure of pneumatic conveying to achieve material movement, and the separator (such as a cyclone separator or a bag filter) then separates the fly ash from the air.

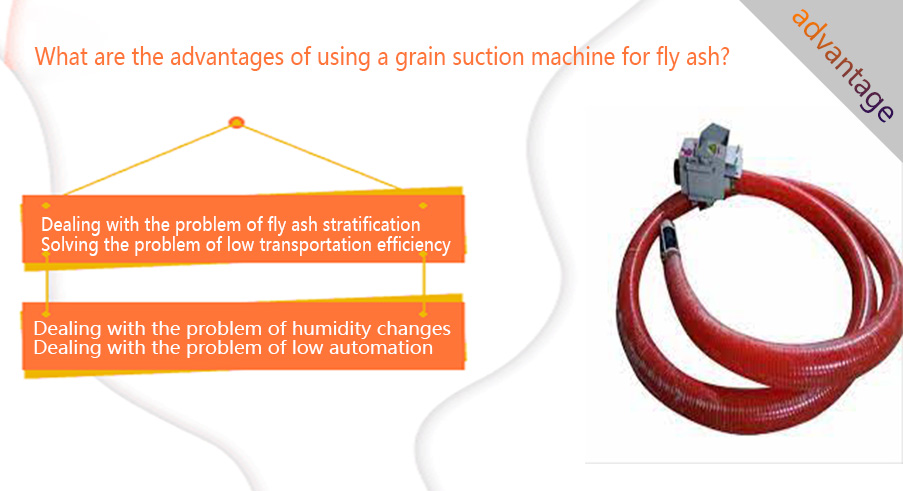

What are the advantages of using a grain suction machine for fly ash?

1. Dealing with the problem of fly ash stratification: Fly ash may be stratified due to particle size differences during transportation, affecting subsequent utilization. During the transportation process, the fly ash is evenly mixed by air flow stirring, and a multi-layer pipeline design is adopted to transport fly ash of different particle sizes separately.

2. Solving the problem of low transportation efficiency: Fly ash has a small particle size and low density, and traditional transportation equipment may be inefficient. Fly ash is evenly distributed in the pipeline through high-frequency vibration.

3. Dealing with the problem of humidity changes: The humidity of fly ash may change with the environment. It is easy to agglomerate when the humidity is too high, and it is easy to raise dust when the humidity is too low. The airflow speed of the grain suction machine can be adjusted according to the humidity changes.

4. Dealing with the problem of low automation: Traditional grain suction machines have a low degree of automation and rely on manual operation. The automation and intelligence of the transportation process can be achieved by introducing a PLC control system.

Comparison between grain sucker and special fly ash conveying equipment

|

Comparison item |

grain sucker |

special fly ash conveying equipment |

|

Applicability |

applicable after modification |

designed specifically for fly ash, strong applicability |

|

Cost |

low modification cost |

high equipment cost |

|

Conveying efficiency |

high, but needs to be optimized |

high efficiency, optimized for fly ash |

|

Environmental protection |

need to add dust removal device |

self-contained high-efficiency dust removal system |

|

Maintenance difficulty |

relatively simple maintenance |

more complex maintenance |

Application of grain sucker for fly ash

1. Conveying and loading and unloading of fly ash:

① Loading and unloading of bulk fly ash: Grain suckers can be used to quickly load bulk fly ash from storage bins or yards into transport vehicles (such as tank trucks), or unload fly ash from vehicles to storage facilities. This greatly improves loading and unloading efficiency and reduces manual labor intensity.

② Storage and transfer of fly ash: Inside the fly ash storage bin, grain suckers can be used to transfer fly ash from one bin to another, or to turn the material in the bin. This helps to maintain the uniformity of fly ash and prevent agglomeration.

2. Reuse of fly ash:

① Application of fly ash in the building materials industry: In the production process of building materials such as cement, concrete, bricks and tiles, grain suckers can be used to transport fly ash to the batching system. This realizes the resource utilization of fly ash and reduces environmental pollution.

② Application of fly ash in the agricultural field: Fly ash can be used to improve soil, and grain suckers can be used to transport fly ash to farmland. This helps to improve soil structure and increase soil fertility.

Grain suction machines for fly ash are a type of equipment that uses negative pressure airflow to transport materials, and are usually used for the transportation of granular materials such as grain and feed. However, after appropriate modification and optimization, grain suckers can also be used for the transportation of fly ash.