Grain processing plant grain suction machine

Tuesday February-25 2025 16:02:41

What is grain processing plant grain suction machine?

Grain processing plant grain suction machine is a kind of equipment used for grain handling. It transports bulk grain through pipelines, greatly improving the handling efficiency of grain processing plants, farms, grain warehouses and other places. Simply put, the grain suction machine is like a "grain vacuum cleaner", which can quickly and efficiently transport grain from one place to another.

Video of grain processing plant grain suction machine

How does a grain processing plant grain suction machine work?

1. Absorbing grain: Grain processing plant grain suction machine sucks the grain raw materials from the warehouse, truck or other storage facilities into the machine through the suction device.

2. Transporting grain: The grain is transported to the destination, such as crusher, screener or other processing equipment, in the conveying system inside grain processing plant grain suction machine.

3. Processing grain: Grain processing plant grain suction machine can perform preliminary processing on the grain as needed, such as crushing, cleaning, grading, etc., to meet the requirements of the subsequent processing production line.

What is the main function of the grain suction machine in the grain processing plant?

Efficient transportation: Grain processing plant grain suction machine can quickly transport grain from the unloading point to the warehouse, processing equipment and other locations, such as quickly sucking the grain on the truck and transporting it to the feed port of the granary or processing workshop, improving the efficiency of grain transportation.

Reduce labor intensity: Reduce the workload of manual grain handling, reduce the labor intensity of workers, and free workers from heavy physical labor.

Ensure grain quality: During the transportation process, dust removal, impurity removal and other devices can be configured to perform preliminary cleaning of the grain, remove dust, impurities, etc., to ensure the quality of the grain.

Flexible layout: According to the layout and production process of the grain processing plant, the pipeline layout and equipment installation can be flexibly carried out to realize grain transportation in different directions such as horizontal, inclined, and vertical to meet different production needs.

What are the advantages of grain processing plant grain suction machines?

1. Solve the problem of grain damage and extrusion: Traditional mechanical conveying methods are prone to extrusion and damage to grain, affecting the quality of grain. In particular, some fragile grains, such as rice and corn, are more susceptible to damage. Grain processing plant grain suction machine uses pneumatic conveying, and the grain is suspended in the pipeline, which reduces the friction and extrusion between grains and reduces the breakage rate of grain.

2. Deal with the problem of low handling efficiency: Traditional manual handling methods are inefficient and labor-intensive, and it is difficult to meet the production needs of large grain processing plants. The conveying speed and distance of open conveyor belts are also limited. Grain processing plant grain suction machines use pneumatic conveying or spiral conveying to quickly and efficiently transport grain.

3. Solve the problem of grain loss and pollution: Traditional grain handling methods, such as manual handling or open conveyor belts, are prone to grain spillage and loss. Grain is easily contaminated by dust, impurities, pests, etc. during transportation, affecting the quality of grain. Grain processing plant grain suction machine uses closed pipeline transportation to effectively reduce the spillage and loss of grain.

4. Dealing with pests and mildew: Grain is easily attacked by pests and mildew during storage and transportation, which affects the safety and quality of grain. Especially in a high temperature and high humidity environment, grain is more likely to mildew. Grain processing plant grain suction machine can be used with ventilation equipment to realize grain storage and ventilation, reduce the humidity and temperature of grain, and reduce the occurrence of pests and mildew.

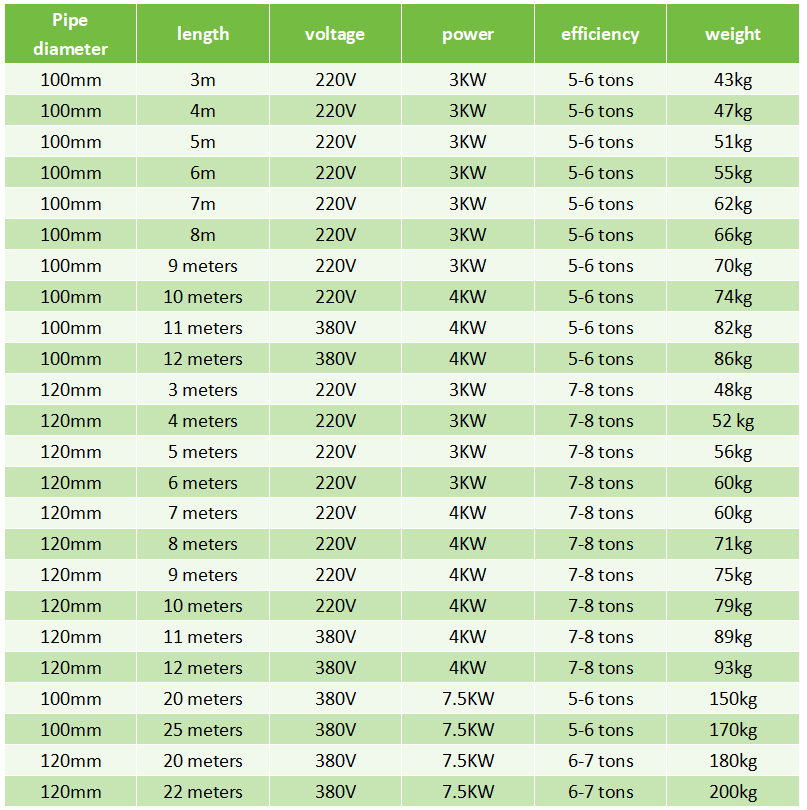

How much grain can a grain processing plant grain suction machine suck?

Application scenarios of grain processing plant grain suction machines

1. Receiving and warehousing raw materials: Grain processing plants receive raw grain from farmland, grain warehouses or transport vehicles. Grain suction machines can quickly suck bulk grain from the unloading area into warehouses or silos to achieve efficient raw material warehousing. Large flour mills receive wheat from all over the country and quickly transport wheat to different storage silos through grain suction machines.

2. Material transportation within the production line: In each link of grain processing, grain needs to be transported from one process to another. Grain suction machines can realize closed pipeline transportation to reduce material loss and dust pollution. After cleaning and moistening the wheat in the flour mill, it is transported to the grinding unit through a grain suction machine.

3. Finished product outbound and loading: After the grain processing is completed, the finished product needs to be transported to the packaging line or loaded for shipment. Grain suckers can quickly transport finished grains from finished product warehouses or packaging lines to transport vehicles. Packaged flour is transported to trucks or train carriages through grain suckers.

4. Grain cleaning and impurity removal: During grain processing, impurities such as dust, debris, and pests need to be removed from grains. Grain suckers can be used in conjunction with cleaning equipment to achieve grain cleaning and impurity removal. Before the raw materials are stored, grain suckers are used in conjunction with dust collectors, screening machines and other equipment to remove impurities from grains.

5. Grain storage and ventilation: During grain storage, storage and ventilation need to be performed regularly to prevent grain mildew and pests. Grain suckers can be used for grain storage and ventilation operations. When the grain processing plant is hot in summer or humid in rainy season, a grain suction machine is used to empty the grain and ventilate it to keep the grain dry and fresh.

Who is Xinxiang Dahan machinery?

Xinxiang Dahan Machinery has more than ten years of production experience in the conveying and screening industry. Its products serve many industries such as food, chemical, medical, metallurgy, etc. Adhering to the business philosophy of integrity and honesty, we take honesty as the basis, maintain a normal mind, provide customers with high-quality products and services, and provide users with a fair and reasonable sales mechanism and a mutually trusting and mutually beneficial partnership.

Grain processing plant grain suction machines are widely used in grain processing plants, which can significantly improve efficiency, reduce costs and improve the working environment. When selecting and using them, it is necessary to weigh the pros and cons according to the actual situation, select the appropriate equipment and optimize the operation to reduce costs and improve efficiency.