Handheld wood chip suction machine

Friday February-21 2025 18:50:15

Handheld wood chip suction machine is a small, portable material conveying equipment, mainly used to suck and convey light bulk materials such as sawdust, grain, and granular materials. It usually adopts the pneumatic conveying principle, sucking the sawdust through the airflow generated by the fan, and then transporting it to the designated location through the pipeline. It is widely used in agriculture, wood processing, feed processing and other fields, with the characteristics of flexible operation and high efficiency.

How does a handheld wood chip suction machine work?

1. Negative pressure generation: There is an electric motor or engine inside the handheld wood chip suction machine, which drives a fan or impeller through this power source to generate strong negative pressure.

2. Inhalation of particles: When the machine is working, the fan or impeller rotates continuously, generating negative pressure. This negative pressure is connected to the working head through a suction pipe or nozzle, so that the surrounding air and particulate materials are sucked into the machine.

3. Collecting particles: The inhaled particulate materials are sent to a dust bag or dust box through a pipe for collection. In this way, the particulate materials can be effectively collected to prevent them from being scattered on the ground or in the air.

What are the applicable materials for the handheld wood chip suction machin?

Handheld wood chip suction machine is mainly suitable for processing wood chips and similar granular materials, including but not limited to the following types of materials:

1. Wood processing waste: debris generated in various wood processing processes, flake waste generated in wood planing, powder waste generated in wood sawing, and fine wood particles after crushing, and debris generated in the process of tree peeling.

2. Agricultural waste: debris from crop straw after crushing, shells generated after rice threshing, and shells generated after peanut shelling.

3. Other lightweight materials: debris generated in paper processing, debris generated in plastic processing, and debris generated in foam material processing.

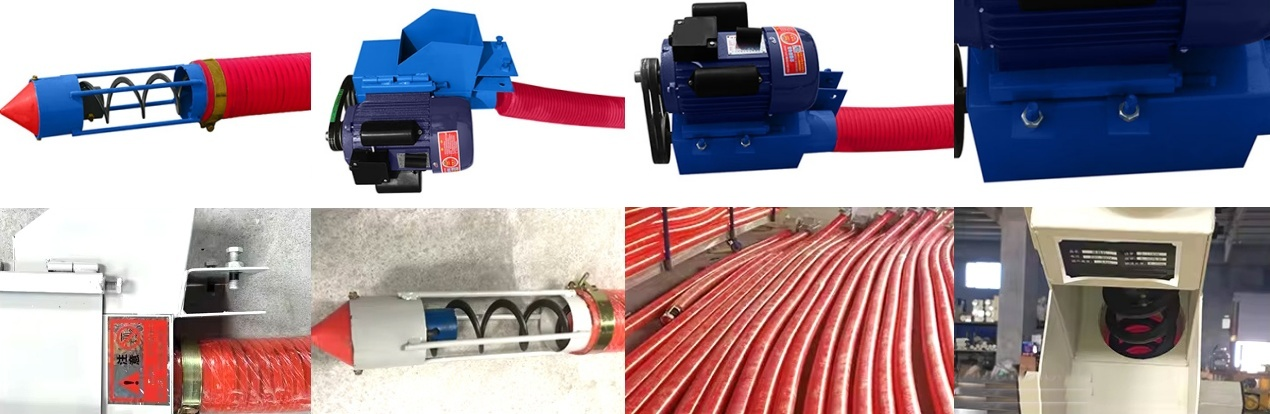

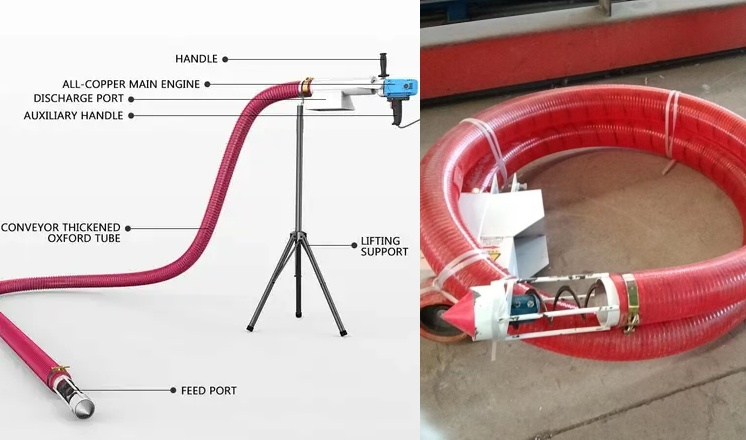

The structure of a handheld wood chip suction machine

handheld wood chip suction machine is usually driven by an electric motor to generate negative pressure to suck in sawdust and granular materials. The suction port at the front of the device is used to suck in sawdust and granular materials. The filtration system includes a filter or filter bag to filter particulate materials in the air to prevent them from entering the motor or other key components.

The suction hose connects the suction port and the motor pipeline to transmit the sucked sawdust and granular materials. The power switch is used to control the on/off button of the motor, which is convenient for the operator to control the start and stop of the equipment. The equipment is usually equipped with a handle to facilitate the operator to hold and operate the equipment.

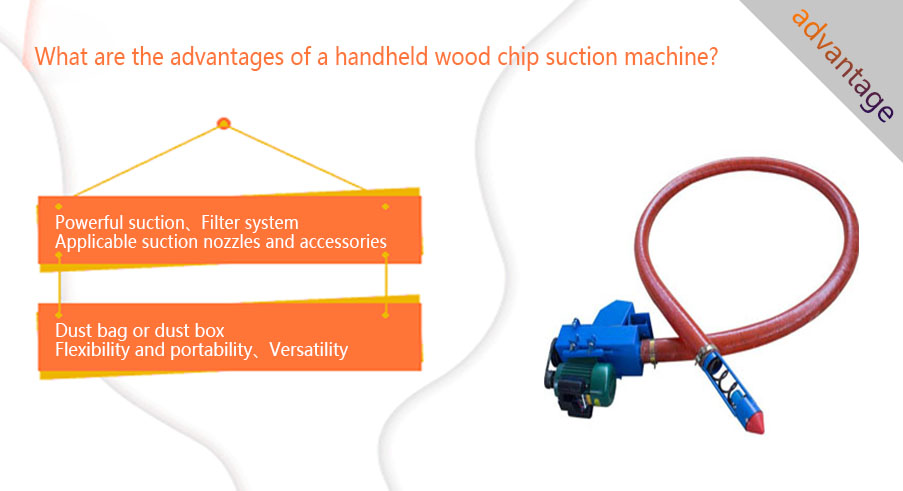

What are the advantages of a handheld wood chip suction machine?

1、Powerful suction: handheld wood chip suction machines usually have strong suction power, which can effectively suck up wood chips and granular materials to prevent them from being scattered on the ground.

2、Filter system: Handheld wood chip suction machine is usually equipped with an efficient filtration system inside, which can prevent wood chips and granular materials from entering the key parts of the machine, such as the motor or fan, to avoid blockage and damage.

3、Applicable suction nozzles and accessories: Handheld wood chip suction machines are usually equipped with different types of suction nozzles and accessories. You can choose the appropriate suction head according to the specific situation to more effectively absorb wood chips and granular materials of different shapes and sizes.

4、Dust bag or dust box: Handheld wood chip suction machines are usually equipped with dust bags or dust boxes, which can effectively collect and store the sucked wood chips and granular materials to prevent them from being scattered during transportation.

5、Flexibility and portability: Handheld wood chip suction machines are usually lightweight and portable, flexible and convenient to operate, and can flexibly handle the cleaning and collection of wood chips in different scenarios.

6、Versatility: Handheld wood chip suction machine is also versatile and can be used to clean different types of granular materials, such as dust, debris, etc., providing a wider range of applications.

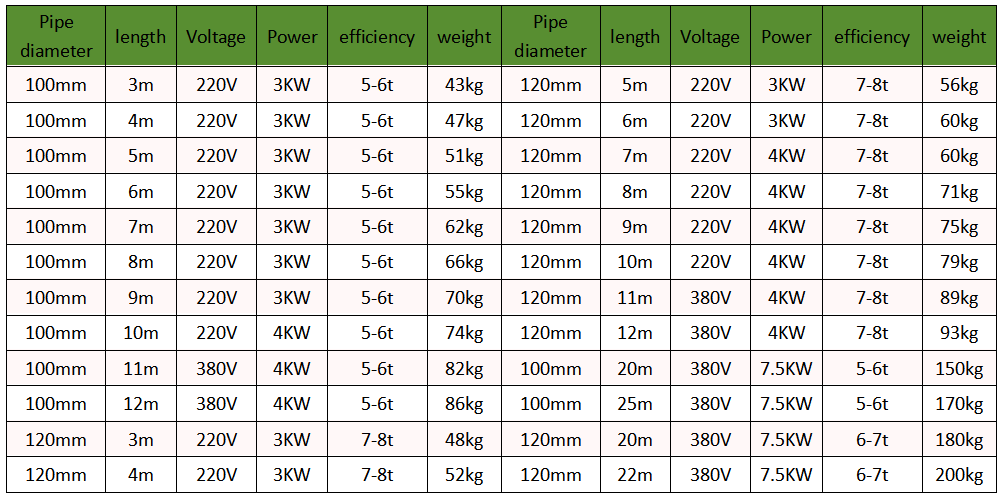

Technical parameters of handheld wood chip suction machine

What is the handheld wood chip suction machine used for?

1. Wood processing plant: During the wood processing process, a large amount of sawdust will be generated. Handheld wood chip suction machine can quickly clean up these sawdust and keep the workplace clean. Transport the sawdust to the silo, boiler or transport vehicle for subsequent processing or utilization. Clean up the sawdust remaining on woodworking machinery and equipment to reduce equipment failures.

2. Furniture factory: A large amount of sawdust and shavings will be generated during the furniture production process. Handheld wood chip suction machine can quickly clean up these waste materials. Collect the wood scraps generated during the cutting process for reuse or processing.

3. Agriculture and breeding: Transport sawdust to livestock and poultry houses as bedding to keep livestock and poultry houses dry and hygienic. Clean up sawdust and feed residues generated during feed processing. Handheld wood chip suction machine can transport sawdust to areas such as flower beds to cover the soil, maintain soil moisture and inhibit weed growth, and clean up dead branches and leaves in the garden, which is convenient and fast.

4. Home and small workshops: clean up the sawdust and shavings generated by woodworking enthusiasts during the production process, keep the work area clean, and handheld wood chip suction machine can also clean and collect sawdust.

5. Outdoor woodworking activities: Handheld wood chip suction machine can be used to clean up sawdust, keep it tidy, and improve production efficiency. In outdoor woodworking activities, such as pruning trees, building wooden structures, etc., handheld wood chip suction machine can be used to clean up the sawdust generated on site and keep the surrounding environment clean.

Precautions for handheld wood chip suction machine

Material characteristics: wood chip handheld suction machine is suitable for conveying dry and light materials. For wet, sticky or heavy materials, the conveying effect will be affected.

Safe operation: Operators should wear protective glasses, masks and other protective equipment to avoid wood chip splashing or dust inhalation.

Equipment maintenance: Regularly clean the suction pipe, aggregate bag and other parts to keep the equipment clean.

Handheld wood chip suction machine manufactures

Handheld wood chip suction machine is a practical small equipment, especially suitable for scenes that require flexible operation. Through reasonable selection and correct maintenance, work efficiency can be significantly improved and labor intensity can be reduced. If you need to handle a large amount of materials or special materials, it is recommended to choose more professional equipment.