How to choose screw conveyor machine?

Wednesday February-28 2024 12:13:56

When choosing a screw conveyor machine for your specific application, several factors need to be considered to ensure that the conveyor meets your material handling requirements effectively. Here are some key factors to consider when selecting a screw conveyor machine:

1. Material Characteristics:

Type of Material: Consider the type of material you need to convey (e.g., powders, granules, liquids, abrasive materials) as different materials may require specific screw designs and conveyor configurations.

Bulk Density: The bulk density of the material will impact the size and capacity of the screw conveyor needed to transport the material efficiently.

Abrasiveness: If the material is abrasive, you may need a screw conveyor with wear-resistant components to ensure durability and longevity.

2. Capacity and Throughput:

Required Flow Rate: Determine the desired material flow rate or throughput that the screw conveyor needs to handle to ensure it can meet your production requirements.

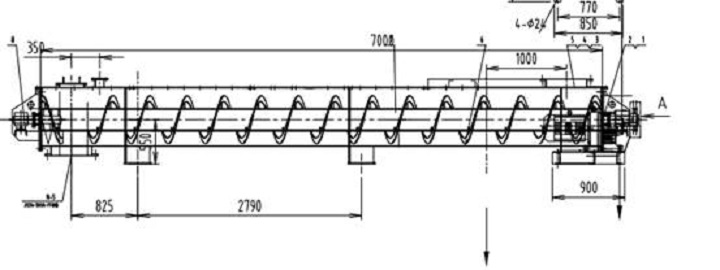

Conveyor Size: Select a screw conveyor size that can accommodate the required capacity while considering factors like screw diameter, length, and pitch.

3. Operating Conditions:

Operating Environment: Consider the environmental conditions where the screw conveyor will operate, including temperature, humidity, and exposure to corrosive substances, to choose a conveyor with suitable materials and coatings for longevity.

Incline or Decline: Determine if the conveyor needs to operate on an incline, decline, or horizontally, as this will impact the design and configuration of the screw conveyor.

4. Layout and Space Constraints:

Space Availability: Consider the available space in your facility to determine the appropriate length, configuration, and orientation of the screw conveyor.

Integration: Ensure that the screw conveyor can be integrated seamlessly into your existing production line or material handling system.

5. Maintenance and Cleaning:

Ease of Maintenance: Choose a screw conveyor machine that is easy to maintain, with accessible components for inspection, cleaning, and servicing.

Cleaning Requirements: If the material being conveyed requires frequent cleaning, consider a screw conveyor design that facilitates easy cleaning and sanitation.

6. Safety and Regulations:

Safety Features: Ensure that the screw conveyor machine meets safety standards and regulations to protect operators and comply with workplace safety guidelines.

Noise and Dust Control: Consider features that help minimize noise levels and dust emissions to create a safer and healthier work environment.

7. Budget and Long-Term Considerations:

Cost: Evaluate the initial cost of the screw conveyor machine, considering your budget constraints, but also consider long-term operating costs, maintenance expenses, and potential energy efficiency.

Future Expansion: Anticipate future production needs and growth to choose a screw conveyor machine that can be easily scaled or modified to accommodate future requirements.

By carefully considering these factors and conducting a thorough assessment of your material handling needs, operating conditions, and production requirements, you can choose the right screw conveyor machine that will optimize material flow, enhance efficiency, and meet your specific application demands effectively. Consulting with a screw conveyor manufacturer or supplier can also provide valuable insights and guidance in selecting the most suitable conveyor for your needs.