How to select the right vibratory feeder

Thursday March-31 2022 15:56:44

Vibrating feeders are often used in conjunction with other machines to automatically convey materials between machines and automate the production process. According to different needs, two different feeders, motor and electromagnetic, can be selected.

But how to choose? Let's find out together:

1. Feeding quantity accuracy

Compared with the motor vibrating feeder, the electromagnetic vibrating feeder is driven by an electromagnetic vibrator and controlled by an electromagnetic force, and the excitation force is small. The quantitative feeding can be realized by setting the parameters, which is more suitable for the accuracy of the feeding quantity. high material.

2. Feeding amount

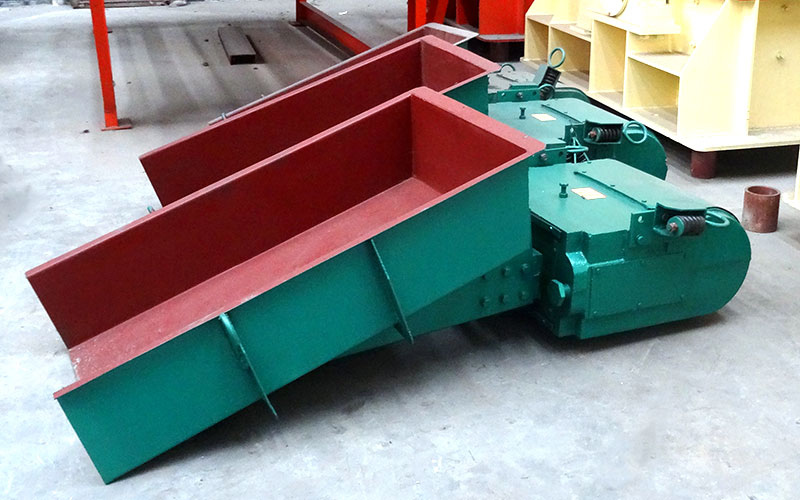

The motor vibrating feeder is driven by a motor, which has a stronger driving force for the feeding trough, and can better convey heavier materials (corn, potatoes, sand and gravel, etc.), and is suitable for production processes that require a large amount of feeding;

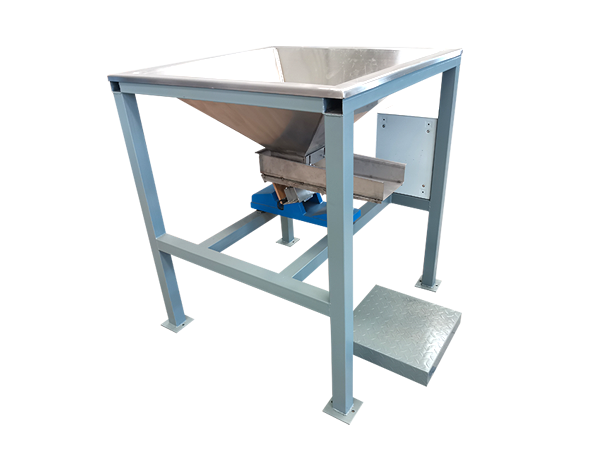

The vibration force of the electromagnetic vibrating feeder is weak and the damage to the material is small. It is suitable for the conveying of fragile and light specific gravity materials (potato chips, spices, coffee powder, etc.), but because the feeding is more gentle, its feeding amount is small. .

3. Productivity

Take river sand as an example: the productivity of the motor vibrating feeder is given by the river sand as the standard material (the bulk specific gravity is 1.6T/m3). When the bulk specific gravity of the material is greater than 1.6T/m3, the output can be selected according to the rated value; when the bulk specific gravity of the material is 1.2-1.6T/m3, the output can reach 0.9-1.0 times the rated output. When the specific gravity of the material stack is 0.8-1.2T/m3, its output can reach 0.8-0.9 times of the rated value. When the specific gravity of the material pile is less than 1.6T/m3, the thickness of the material layer must be appropriately increased to increase the output. For materials that are difficult to convey by the vibrating feeder (such as talc, titanium dioxide, white mud, flour, clay, etc.), as well as hydrophilic materials with large water content, the output should be determined according to the test. If necessary, the tank body should be properly inclined and installed (generally inclined downward by 10 to 15 degrees) to increase the feeding amount.

4. Feeder usage conditions

(1) The ambient temperature does not exceed +40℃;

(2) When the ambient temperature is 20±5℃, the relative humidity of the surrounding medium is not more than 85%;

(3) There is no medium that is seriously corroded and affects electrical insulation around.

5. If space is limited, products can be customized

If the space distance limit width is encountered during the selection, it can be considered to change the vibration motor to rear installation to reduce the width size. Or design and customize a suitable product together with the manufacturer.

The explanation of "How to choose a suitable vibrating feeder?" is here. If you have any questions, please contact us.