Inclined screw conveyor for putty powder

Friday September-20 2024 11:53:01

Putty powder is a fine powdered material commonly used in construction and renovation projects. Inclined screw conveyors rs are a common mechanical conveying system used to move materials within a certain angle. When designing an inclined screw conveyor for handling putty powder, it is necessary to consider the material flow characteristics, the inclination angle, and the need to prevent dust dispersion.

1.Function of putty powder inclined screw conveyor

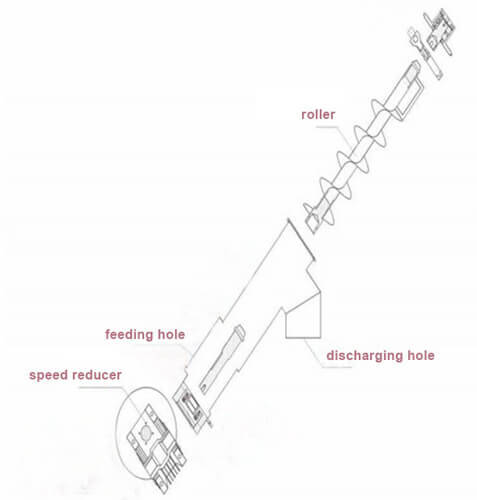

Inclined screw conveyor for putty powder is a mechanical device that uses spiral blades to rotate in the casing to continuously convey materials along the axial direction. When the spiral blades rotate, the blades push the materials forward, and at the same time, the materials slide down along the inclined casing under the action of gravity, thereby realizing the conveying of materials.

2.Application of putty powder inclined screw conveyor

Inclined screw conveyors for putty powder have a wide range of applications in the construction industry and decoration projects. Here are some common situations regarding the application of inclined screw conveyors for putty powder:

Construction sites: On construction sites, putty powder is often used to fill and repair cracks and depressions in walls and ceilings. Inclined screw conveyors can be used to transport putty powder from one location to another to facilitate construction workers to carry out repair and decoration work in the work area.

Decoration construction: In interior decoration construction, putty powder is often used for plastering and repairing walls and ceilings. Inclined screw conveyors can transport putty powder to where it needs to be constructed, improve construction efficiency and reduce the workload of manual handling.

Production plants: In putty powder production plants, inclined screw conveyors can be used to transport putty powder from one stage of the production line to another, or to transport finished products to the packaging area. This helps to improve production efficiency and reduce production costs.

Warehousing and packaging: Inclined screw conveyors can also be used to transport containers or packaging boxes filled with putty powder from one location to another, such as from a production line to a storage area or packaging area.

Custom Applications: Depending on specific production needs and process flows, Inclined Screw Conveyors can be custom designed upon request to meet specific conveying requirements and space constraints.

3.Advantages of putty powder inclined screw conveyor

Strong adaptability: It can adapt to the conveying of various materials such as powder and granular materials, and has good adaptability to sticky materials such as putty powder.

Good sealing: It can effectively prevent dust from flying and improve the production environment.

Adjustable conveying capacity: The conveying capacity can be easily adjusted by adjusting the motor speed or changing the gap between the spiral blades.

Simple structure: Easy to install, maintain and operate.

Small footprint: It can be flexibly arranged according to the layout of the production line.

4.Selection suggestions for putty powder inclined screw conveyor

Material properties: The density, particle size, viscosity, etc. of putty powder have a direct impact on the selection of conveyor.

Conveying capacity: Determine the conveying capacity of the conveyor according to production requirements.

Conveying distance: The length of the conveyor will affect the power and structure of the conveyor.

Conveying angle: The inclination of the conveyor will affect the conveying effect and power consumption.

Working environment: Factors such as temperature and humidity in the working environment will also affect the selection of the conveyor.

In short, as an efficient and reliable conveying equipment, the putty powder inclined screw conveyor plays a vital role in the putty powder production process. By understanding its working principle, advantages, application scenarios and selection considerations, we can better select and use the equipment, improve production efficiency and improve the production environment.