Inclined screw conveyor for salt

Saturday September-21 2024 11:45:06

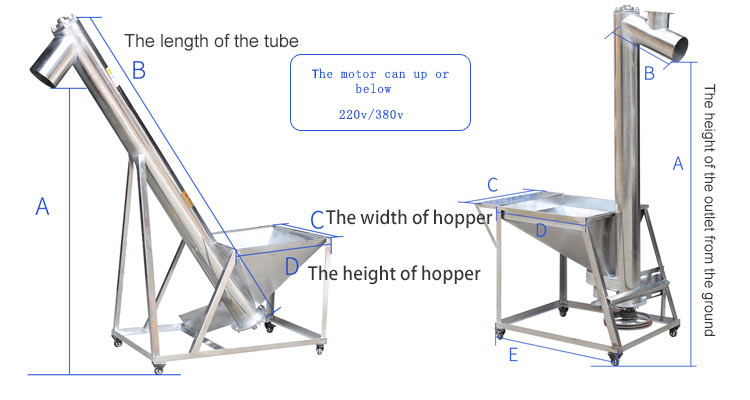

Inclined screw conveyor for salt is a device used to transport salt or similar granular materials. It is usually composed of a screw shaft, a screw blade, a bearing seat, a transmission device and other components. The working principle of the screw conveyor is to use the screw blade to rotate in the pipeline to transport the material along the length of the pipeline. Compared with the horizontal conveyor, the inclined screw conveyor can better meet the needs of angled transportation, such as transporting salt from one location to another in industrial production.

1.Function of Inclined Screw Conveyor for Salt

Inclined screw conveyors for salt play a key role in salt production, and their functions include but are not limited to the following:

Conveying salt particles: The main function is to transport salt particles from one location to another, which can be from the production line to the packaging area, or from the storage warehouse to the production line, etc.

Mixing and stirring: During the process of conveying salt, the rotation of the spiral blades can also mix and stir the salt particles to ensure the uniformity of the salt.

Unloading: The inclined screw conveyor can be used as a unloading device to quickly and efficiently unload salt from a container or storage warehouse to the required location.

Adjusting flow: The conveying speed and flow of salt can be adjusted by controlling the rotation speed or tilt angle of the spiral blade to meet production needs.

Continuous conveying: The screw conveyor can achieve continuous conveying to ensure the continuity and efficiency of the production line.

Automated production: It can be used in conjunction with an automated control system to achieve automated conveying and processing of salt and improve production efficiency.

2.Application of Inclined Screw Conveyor for Salt

Inclined screw conveyors for salt have many application scenarios in salt production, mainly including but not limited to the following aspects:

Salt production line: In the salt production line, inclined screw conveyors are often used to transport raw salt particles from the extraction or processing link to the next processing stage, such as drying equipment or packaging area.

Salt packaging: During the salt packaging process, inclined screw conveyors can transport packaged salt bags or salt boxes from the packaging area to the stacking area for subsequent storage or transportation.

Salt storage: Inclined screw conveyors can also be used to transport salt particles inside the salt warehouse to help manage and optimize salt storage space.

Salt processing: During the salt processing process, inclined screw conveyors can be used to transport salt particles to different processing equipment, such as grinders, screening machines, etc., to complete the further processing of salt.

Salt packaging line: In the salt packaging production line, inclined screw conveyors are usually used to transport salt particles from weighing or packaging machines to equipment such as sealing machines or coding machines.

Salt export/transportation: During the salt loading or loading process, inclined screw conveyors can be used to transport salt particles from storage warehouses or production lines to loading equipment for shipment to the destination.

3.Advantages of Inclined Screw Conveyor for Salt

Inclined screw conveyors for salt have many advantages in salt production, including but not limited to the following:

Wide applicability: It can be used to convey salt particles of various shapes and sizes, and is suitable for different salt production links.

Simple structure: The equipment structure is relatively simple, easy to install and maintain, and reduces the maintenance cost of the production line.

Small footprint: Compared with other conveying equipment, the inclined screw conveyor occupies a small area and is suitable for salt transportation in a limited space.

High efficiency and energy saving: It has high conveying efficiency and can convey salt particles quickly and continuously, saving labor costs and improving production efficiency.

Reliable and stable: It has stable and reliable operation, reducing failures and downtime in the production process and ensuring production continuity.

Strong flexibility: The conveying speed and flow rate can be adjusted according to production needs to adapt to the needs of different production environments.

High safety: The equipment runs smoothly and is easy to operate, reducing the safety risks of operators.

4.Selection suggestions for inclined screw conveyors for salt

Here are some tips when choosing an inclined screw conveyor for salt:

Conveying capacity: Determine the required salt conveying volume and conveying distance in order to select the appropriate conveyor model and size.

Salt particle characteristics: Consider the particle size, density, humidity and other characteristics of the salt, and select a screw conveyor that suits these characteristics.

Working environment: Consider the temperature, humidity, dust and other factors of the working environment, and select corrosion-resistant and wear-resistant materials and coatings.

Tilt angle: Determine the tilt angle according to actual needs to ensure that the salt particles can be transported stably.

Conveying distance: Consider the distance and height that the salt needs to be transported, and select the appropriate screw conveyor length and tilt angle.

Maintenance: Choose a design that is easy to maintain and clean to ensure long-term stable operation of the equipment.

Automation requirements: If integration with an automated control system is required, select a screw conveyor model that supports automated control.

Production requirements: According to the production capacity and production requirements of the production line, select the appropriate conveyor model and specifications to meet production needs.

In short, the inclined screw conveyor for salt is an efficient and reliable material conveying equipment, which is widely used in salt, food, chemical and other industries. Through reasonable selection and maintenance, its advantages can be fully utilized to improve production efficiency.