Introduction to the basic situation of shaft screw conveyor

Thursday February-09 2023 14:41:00

Shafted screw conveyors are a very conventional type of conveyor used for conveying medium to medium flowing powders, granular materials and, in a few cases, materials with a high liquid content.

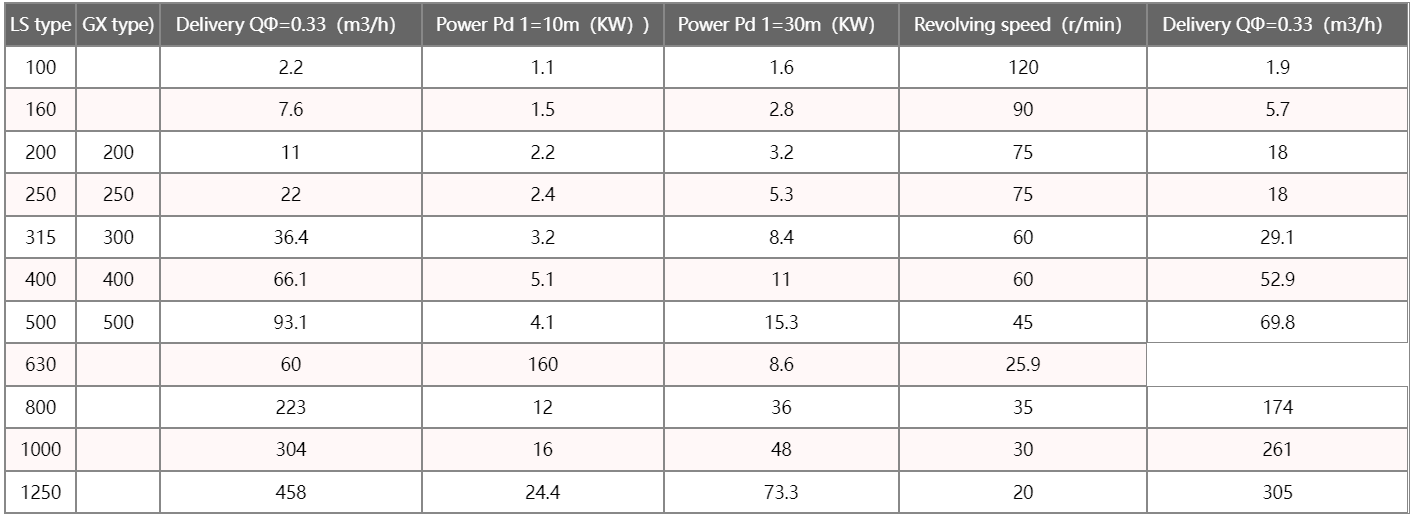

There are two types of shaft screw conveyors according to the specifications, LS and GX. The conveying volume and conveying distance of the LS type are larger than the GX type, but in terms of the conveying inclination, the GX type can realize a larger inclination angle conveying (GX type inclination > 20°, LS type inclination ≤15°).

The screw blade of the shaft screw conveyor is seamlessly connected with the screw shaft, and the screw shaft can be fixed. In this case, it can ensure that the screw blade is more stable when conveying materials, and the spiral pipe groove will not be caused by the weight of the blade and the weight of the material falling. Damage; the helical blade is not easy to be twisted and broken.

However, due to the existence of the screw shaft of the shafted screw conveyor, it will affect the flow of viscous materials, or cause entanglement when conveying belt-shaped materials, and eventually lead to blockage, so the shafted screw conveyor is mainly used for conveying good fluidity , Powder or granular materials that are not easy to agglomerate and block.

According to the condition of the material, there are usually two choices of carbon steel and stainless steel. Carbon steel is used for conventional product transportation, and the shaft screw conveyor made of stainless steel can be used for conveying high temperature, high hygiene standards or corrosive materials. Of course, as It is also possible to design machines with other materials if necessary, or choose to spray special coatings on the surface of the screw conveyor (such as Teflon coating, plastic spraying treatment, special paint, etc.).

Conventional Product Models of Shaft Screw Conveyors