Large capacity bucket elevator for mines

Friday February-14 2025 14:51:50

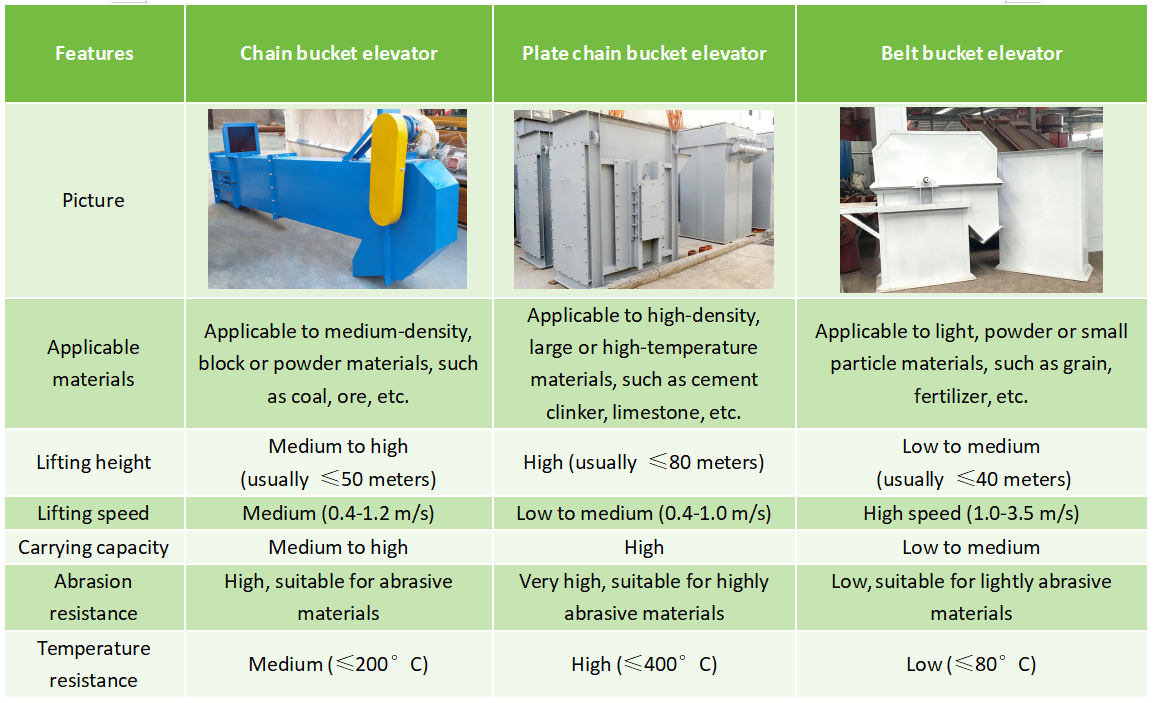

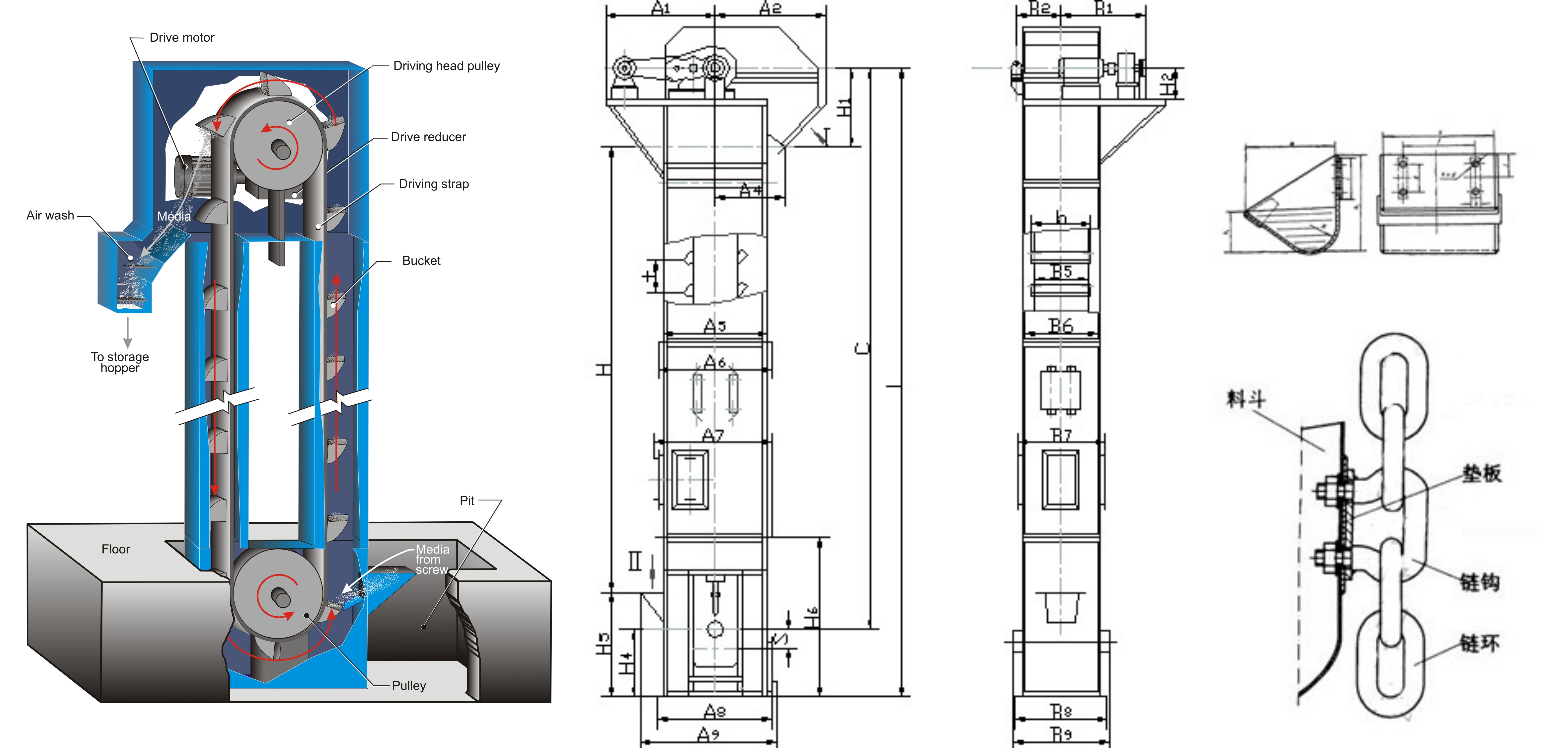

Large capacity bucket elevator for mines is a vertical conveying equipment used in the mining industry to vertically transport bulk materials such as ore, coal, minerals and other mining products. The equipment consists of a series of buckets connected to a belt or chain for vertically lifting materials.

Video of the large capacity bucket elevator for mines

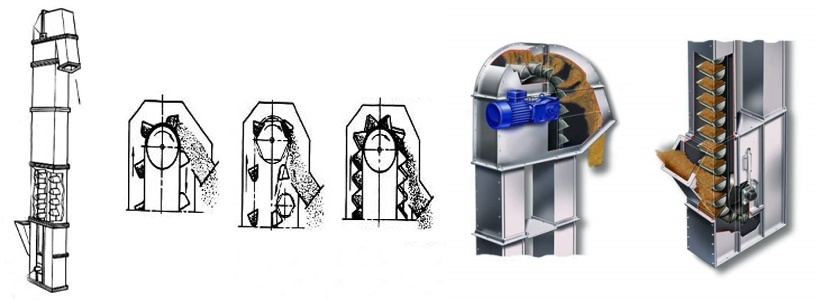

How do the large capacity bucket elevator for mines work?

1. Small bucket elevator: The capacity is about 10-50 tons/hour, which is suitable for small-scale mines or low-production scenarios. For example, the capacity range of NE plate chain bucket elevator is 15-800 m³/h.

2. Medium bucket elevator: The capacity is about 50-500 tons/hour, which is suitable for medium-sized mines or medium-production material lifting. For example, the capacity range of TH ring chain bucket elevator is 35-1850 m³/h.

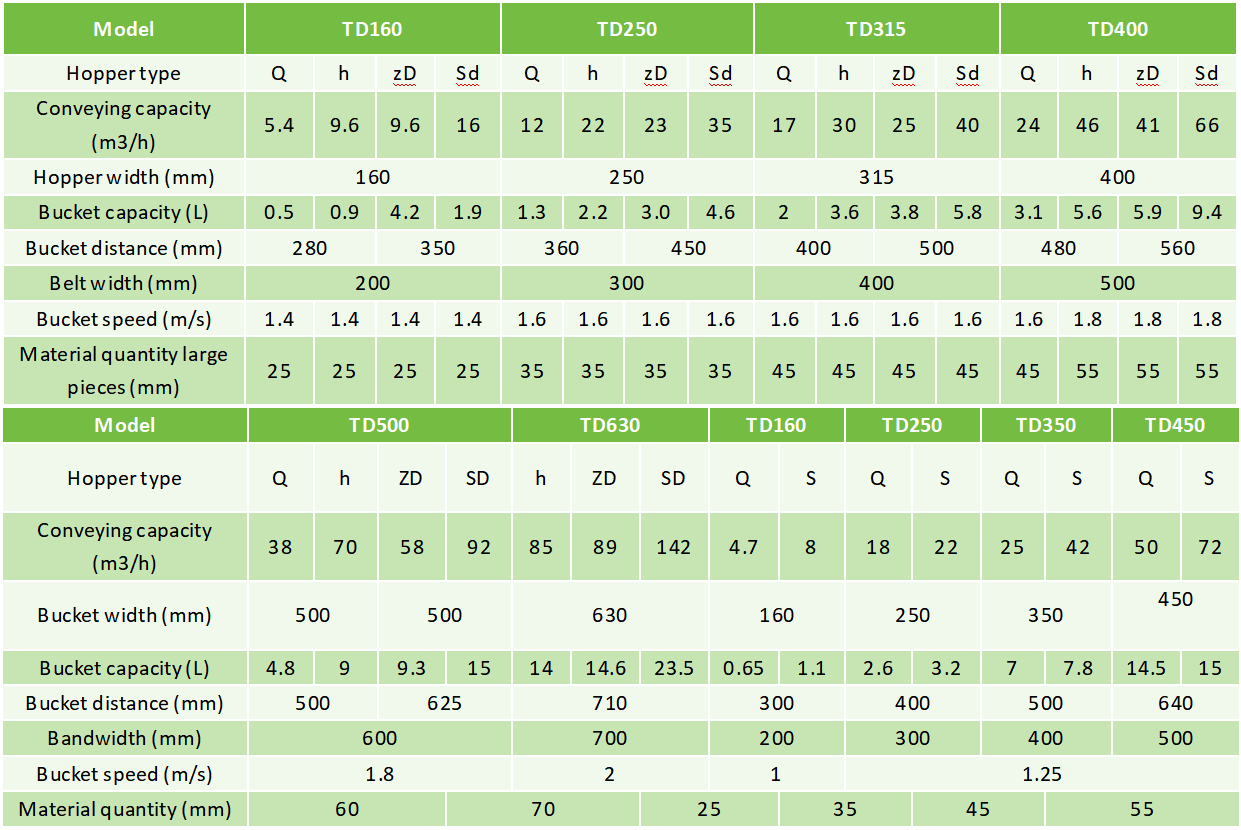

3. Large bucket elevator: The capacity can reach 500-2000 tons/hour or even higher, which is suitable for large-scale mines or high-production material lifting. For example, the capacity range of TD belt bucket elevator is 4-238 m³/h.

Specifications of large capacity bucket elevators for mines

How do you increase large capacity bucket elevator for mines?

Increase the size of the hopper: Choosing a larger hopper can increase the amount of lifting per time. The increase in hopper size will affect the lifting speed and the overall structural strength of the equipment, and a comprehensive evaluation is required.

Increase the lifting speed: Under the premise of ensuring safety, appropriately increasing the lifting speed can increase the lifting amount per unit time. Too fast a lifting speed may cause material spillage and increased equipment vibration.

Optimize the hopper layout: Reasonable design of the hopper spacing and arrangement can increase the number of hoppers per unit length, thereby increasing the lifting capacity.

Improve the feeding method: Using a uniform and continuous feeding method can avoid insufficient or overloaded hoppers and improve lifting efficiency. Equipped with a drive device with appropriate power to ensure stable operation of the equipment under full load.

Advantages of large capacity bucket elevator for mines

1. High Capacity: Large mining bucket elevators are designed to efficiently handle large amounts of material, making them suitable for mining operations that require vertical transportation of large amounts of material. The equipment is made of sturdy materials to withstand the harsh conditions common in mining environments.

2. High Lifting Height: Large mining bucket elevators are able to lift materials to considerable heights, enabling efficient vertical transportation in mining operations. The bucket is designed to effectively scoop and transport materials, optimizing material handling efficiency.

3. Safety Features: Large mining bucket elevators use safety mechanisms to ensure safe operation of the equipment and protect equipment and personnel. Some modern large mining bucket elevators are equipped with automation and control systems for efficient operation and monitoring.

4. Versatility: Large mining bucket elevators can handle a wide range of materials commonly found in mining operations, making them versatile and essential equipment in the industry.

Application of large capacity bucket elevator for mines

In the mining industry, large capacity bucket elevator for mines is a key equipment, mainly used for efficient and continuous transportation of large amounts of bulk materials such as ore, coal, limestone, tailings, etc. in vertical or inclined directions.

What is the standard size of a large capacity bucket elevator for mine?

Large capacity bucket elevator for mines manufacturers

Overall, large capacity bucket elevator for mines play a vital role in facilitating the vertical transportation of bulk materials in mining operations, helping to streamline production processes, improve efficiency and reduce manual handling requirements.