Lime powder flexible screw conveyor

Monday March-17 2025 16:37:44

Lime powder flexible screw conveyor is a conveying equipment specially used for conveying powdered and fine granular materials (such as lime powder, flour, cement powder, etc.), which is widely used in building materials, chemical industry, environmental protection, food and other industries. It uses flexible spiral blades or spring spirals to convey materials through pipelines, which is suitable for conveying needs of short distances or curved paths.

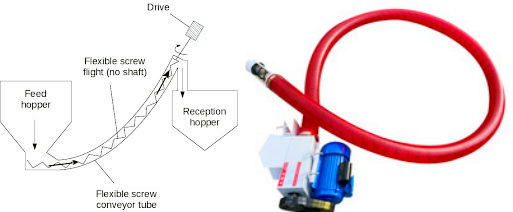

What is the working principle of the lime powder flexible screw conveyor?

Lime powder flexible screw conveyor is mainly composed of a drive device, a spiral body, a conveying pipeline and an inlet and outlet.

The drive device drives the spiral body to rotate, and the spiral body rotates in the conveying pipeline to convey lime powder and other materials along the pipeline.

The spiral body of the flexible screw conveyor is usually made of flexible material and can be bent, thereby realizing the curved conveying of materials.

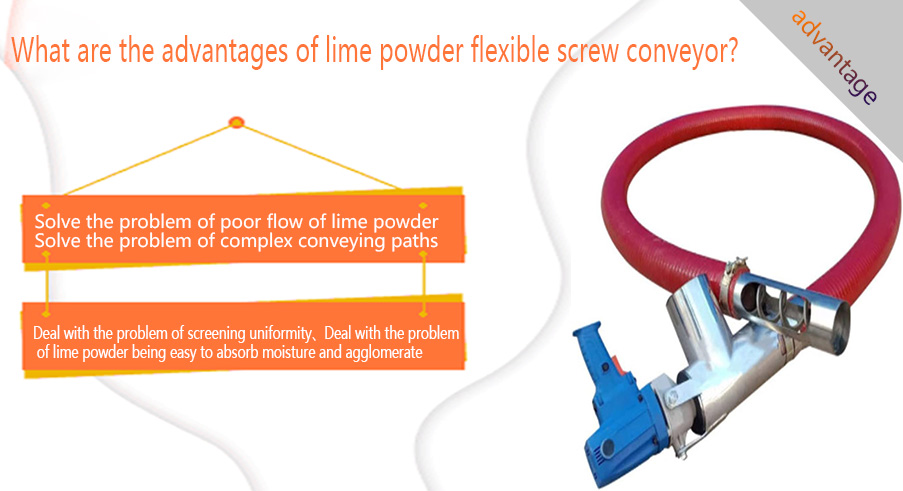

What are the advantages of lime powder flexible screw conveyor?

1. Solve the problem of poor flow of lime powder: lime powder has poor flowability, and uneven feeding may cause local overload of the screen during screening. The flexible screw conveyor for lime powder achieves a constant conveying rate through motor speed regulation to avoid fluctuations in feeding.

2. Solve the problem of complex conveying paths: screening equipment usually needs to be connected to storage bins, packaging machines, etc., and the plant space is complex. The pipes of the flexible screw conveyor can be bent to adapt to non-linear paths in the plant or construction site.

3. Deal with the problem of screening uniformity: the particle size distribution of lime powder is uneven, and overscreening or underscreening may occur during screening. The flexible screw conveyor uses frequency conversion speed regulation and flow sensors to accurately control the conveying volume to avoid overloading the screening machine.

4. Deal with the problem of lime powder being easy to absorb moisture and agglomerate: lime powder has strong hygroscopicity and is easy to agglomerate in a humid environment. The flexible screw conveyor for lime powder adopts closed conveying to prevent external moisture from entering and reduce the risk of lime powder absorbing moisture and agglomerating.

Technical parameters of lime powder flexible screw conveyor

|

Parameter name |

unit |

specification range |

|

Screw diameter |

mm |

40~200 |

|

Conveying capacity |

m³/h |

0.5~20 |

|

Conveying distance |

m |

≤30 (single machine), can be extended in series |

|

Screw speed |

rpm |

100~300 |

|

Pipeline material |

- |

carbon steel, stainless steel (304/316), wear-resistant lining |

|

Screw material |

- |

spring steel, stainless steel |

|

Drive power |

kW |

0.75~7.5 |

|

Conveying angle |

° |

0~90 (bendable arrangement) |

|

Inlet and outlet size |

mm |

50~250 |

|

Conveying mode |

- |

horizontal, inclined, vertical |

|

Sealing mode |

- |

fully enclosed, dustproof design |

|

Applicable materials |

- |

lime powder, cement powder, flour, carbon black, fly ash, etc. |

Application of Lime Powder Flexible Screw Conveyor

1. Environmental Protection Industry: Lime Powder Dosing System for Water Treatment

In environmental protection projects such as water plants, sewage treatment plants, and flue gas desulfurization, lime powder is often used as a pH regulator, flocculant, and desulfurizer. Lime powder flexible screw conveyor can stably transport lime powder to the dosing device to avoid flow fluctuations affecting the water treatment effect.

2. Dry Mortar and Building Materials Industry

Lime powder is used for wall painting, masonry mortar, plastering, etc. in construction. The construction site space is limited, and the lime powder flexible screw conveyor can flexibly arrange curved paths to meet on-site transportation needs.

3. Agriculture and Animal Husbandry: Feed Additive Transportation

Lime powder is used as soil conditioner, feed additive, and disinfectant in agriculture and animal husbandry. The flexible transportation process avoids long-term retention of powder and reduces agglomeration.

4. Powder recovery system: lime powder recycling

During the production and use of lime powder, some powder may be collected in the dust collector or recovery bin. The flexible screw conveyor can transport it back to the production line to improve resource utilization.

Actual cases and trends of lime powder flexible screw conveyor

❌ Lime powder is easy to absorb moisture and agglomerate, causing blockage?

✅ Solution: Add a vibration device or an air flow device to maintain the fluidity of the powder.

❌ The pipeline wears quickly and has a short service life?

✅ Solution: Use wear-resistant lining or stainless steel to reduce wear and improve durability.

❌ Dust leakage pollutes the environment?

✅ Solution: Closed conveying + negative pressure dust extraction system to avoid dust overflow

Lime powder flexible screw conveyor is a highly efficient, closed, flexible and adaptable conveying equipment, especially suitable for complex conveying routes and scenes with high environmental protection requirements. If you have specific requirements (such as conveying distance, conveying volume, etc.), you can communicate further and we can help you recommend a suitable model or design solution!