Manual feed sucker

Monday March-03 2025 15:54:34

Manual feed sucker is a simple and practical device, mainly used to extract feed from storage containers or transport vehicles. It is a device used in farms, feed processing plants and other places to conveniently and quickly transport feed. Because it is manually operated, it has the characteristics of simple structure, low cost and easy maintenance.

Video of manual feed sucker

How does the manual feed sucker work?

Manual feed sucker generates negative pressure through manual operation, sucks feed from the storage container and delivers it to the target location through the pipeline. It usually includes components such as manual pump, suction pipe and delivery pipe.

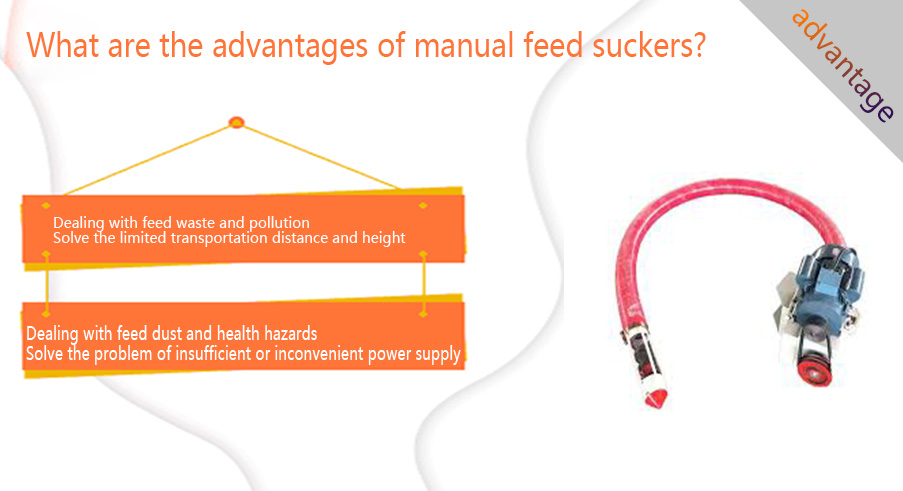

What are the advantages of manual feed suckers?

1. Dealing with feed waste and pollution: During traditional transportation, feed is easily spilled and scattered, causing waste and environmental pollution. Manual feed sucker uses closed pipeline transportation to reduce the scattering and waste of feed. The suction function of the sucker can effectively clean up the scattered feed on the ground and reduce environmental pollution.

2. Solve the limited transportation distance and height: Traditional transportation methods are limited in transportation distance and height, and it is difficult to meet the needs of complex environments. Manual feed sucker can achieve a certain distance and height of transportation through pipeline transportation, adapting to different working environments.

3. Dealing with feed dust and health hazards: Feed will generate a lot of dust during transportation, which will cause harm to the respiratory system of operators. Installing a filter device at the entrance of the sucker can further reduce the generation and spread of dust.

4. Solve the problem of insufficient or inconvenient power supply: In some farms, breeding farms or remote areas, the power supply is insufficient or inconvenient, which limits the use of electric conveying equipment. Manual feed sucker does not require electric drive and relies on manual operation. It is suitable for places without power supply or unstable power supply.

Application of manual feed sucker

1. Small farms: For farmers with small scale and limited funds, manual feed sucker is an ideal choice, which can carry out feed delivery operation anytime and anywhere. In small pig farms and chicken farms in rural areas, farmers can easily use manual feed sucker to transport feed from storage bags or warehouses to feed troughs in breeding houses.

2. Temporary feed transfer: In some temporary feed transfer scenarios, such as site cleaning, equipment maintenance or feed warehouse relocation, feed needs to be temporarily transferred from one place to another. Manual feed sucker can be quickly assembled and disassembled, and can efficiently complete feed transfer tasks.

3. Feed processing workshop: In feed processing workshops, different batches and types of feed may need to be packaged or transported to different processing equipment. Manual feed sucker can flexibly control the delivery volume and delivery position according to actual needs to meet the diversified production needs of small workshops, and the lower cost is also in line with the economic affordability of small workshops.

Structural composition of manual feed sucker

Suction device: usually composed of suction pipe and suction nozzle.

Power device: Manual feed sucker generally generates suction through piston pump or diaphragm pump driven by manpower. Piston pump consists of piston, pump barrel, inlet and outlet check valve and other components.

Conveying pipeline: connects the suction device and the outlet, responsible for conveying the sucked feed to the designated location.

Discharging device: located at the end of the conveying pipeline, discharges the conveyed feed into the target container or storage area.

Steps for using a manual feed sucker

Install the suction tube: insert the suction tube into the feed storage container.

Connect the delivery pipe: connect the delivery pipe to the discharge port of the feed sucker and point it to the target container.

Manual operation: generate negative pressure through the manual pump to start extracting feed.

Complete extraction: stop the operation when the target container is full or the feed in the storage container is exhausted.

Manual feed sucker is an economical and practical feed conveying equipment with wide application prospects in small farms and family farming.