Portable Vehicle Mounted Flexible Screw Conveyor

Sunday April-27 2025 18:35:33

What is a portable vehicle mounted flexible screw conveyor?

Portable vehicle mounted flexible screw conveyor is a material conveying equipment that integrates portability, vehicle mounted mobility, and flexible conveying functions. It combines the flexibility of a flexible screw conveyor and the portability of a vehicle mounted platform. It is suitable for conveying powdered, granular, or small block materials, such as grain, feed, chemical raw materials, etc., which require rapid deployment, frequent movement, or space constraints. It is widely used in agriculture, construction, chemical industry, food processing, and other fields.

Video of portable vehicle mounted flexible screw conveyor

What is the working principle of the portable vehicle mounted flexible screw ?

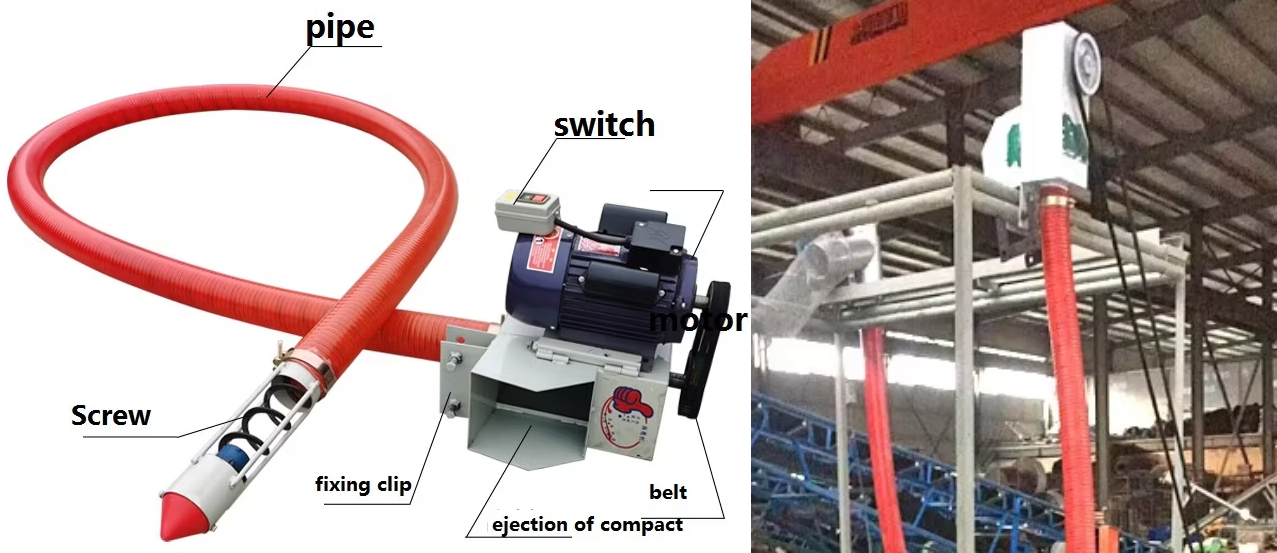

The working principle of the portable vehicle mounted flexible screw conveyor is based on the core mechanism of screw conveying, and combines flexible design and mobile adaptation technology to achieve flexible and efficient conveying of materials in complex scenarios.

① The material enters the conveying pipeline through the feed port and accumulates between the spiral blades.

② The spiral shaft rotates under the drive of the motor, and the friction between the blades and the material pushes the material to move along the axial direction of the pipeline. The spiral blades fit the inner wall of the pipeline through elastic deformation in the bending section to maintain continuous pushing force.

③ When the conveying path needs to bypass obstacles or adjust the angle:

Horizontal bending: The spiral shaft is bent through the hinged structure, and the bellows are deformed synchronously to form an arc conveying path.

Vertical lifting: Increase the screw speed, use centrifugal force to overcome gravity, and realize inclined or vertical conveying (the maximum inclination angle can reach 60°).

④ Material unloading: The material is discharged through the discharge port, and the flow rate can be controlled by adjusting the discharge valve or the screw speed.

Problems in the material conveying process

Portable vehicle mounted flexible screw While improving operating efficiency, conveyors may still face the following problems in actual applications, which need to be avoided through design optimization, operating specifications and maintenance:

Blocking and stagnation: The material humidity is too high (such as wet grain), the particle size is too large (such as agglomerated fertilizer) or the feeding is uneven, resulting in the gap between the spiral blade and the pipe wall being filled.

Material residue and contamination: The bending of the flexible pipe is prone to material accumulation, especially sticky materials (such as wet sand and molasses). The residual material deteriorates and contaminates subsequent batches, increasing the cleaning cost.

Conveying efficiency reduction: After long-term use, the spiral blade wears out, or the flexible pipe ages, resulting in reduced elasticity. The conveying volume decreases and energy consumption increases.

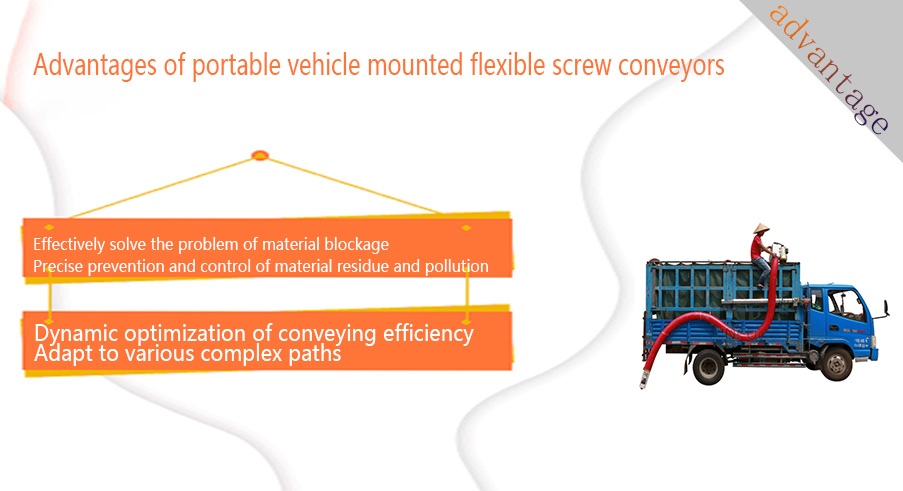

Advantages of portable vehicle mounted flexible screw conveyors

1. Effectively solve the problem of material blockage: The spiral blades are made of spring steel or polymer composite materials, with a smooth surface and a certain elasticity, reducing the friction resistance with the material. Adjust the pitch for different materials: Powdered materials (such as flour) use a small pitch (100-150mm) to avoid dust and backflow. Granular materials (such as fertilizers) use a large pitch (200-300mm) to improve conveying efficiency.

2. Precise prevention and control of material residue and pollution: A flexible scraper (such as polyurethane material) is welded at the end of the blade, and the residual material is scraped against the pipe wall during rotation, with a residual amount of ≤0.5%. The inner wall of the flexible pipe is sprayed with food-grade polytetrafluoroethylene (PTFE), with a friction coefficient as low as 0.04, and the residue of sticky materials (such as molasses) is reduced by 80%.

3. Dynamic optimization of conveying efficiency: Real-time detection of motor load, when the conveying volume drops by 10%, the speed is automatically increased to 120% of the rated value to compensate for efficiency attenuation. Each section of the spiral shaft is driven independently, and only the corresponding section needs to be replaced after local wear. After maintenance, the efficiency is restored to 95% of the new machine. The flexible pipe with high elastic steel wire reinforcement layer has a bending fatigue life of more than 20,000 times, which is 3 times that of ordinary rubber pipes.

4. Adapt to various complex paths: The spiral shaft adopts a multi-section hinged structure, allowing horizontal bending (bending radius ≥ 1.5 times the spiral diameter). The pipe of the portable vehicle mounted flexible screw conveyor uses a corrugated pipe or a segmented hose, which deforms synchronously with the spiral bending.

Comparative advantages of portable vehicle mounted flexible screw conveyor and traditional equipment

|

Pain points in scenarios |

Traditional solutions |

Solutions for portable vehicle mounted flexible screw conveyor |

|

Narrow space, complex paths |

Fixed conveyors cannot bend |

Flexible screws can bypass obstacles and adapt to curved paths |

|

Frequent movement or temporary operations |

Time-consuming equipment installation/disassembly |

Fast deployment on vehicles, support immediate use |

|

Dust pollution or material fragility |

Open transportation leads to dust and damage |

Enclosed pipelines and low friction design to protect materials and the environment |

|

Multi-scenario switching requirements |

Multiple devices required |

Modular design, adapt to different materials by replacing components |

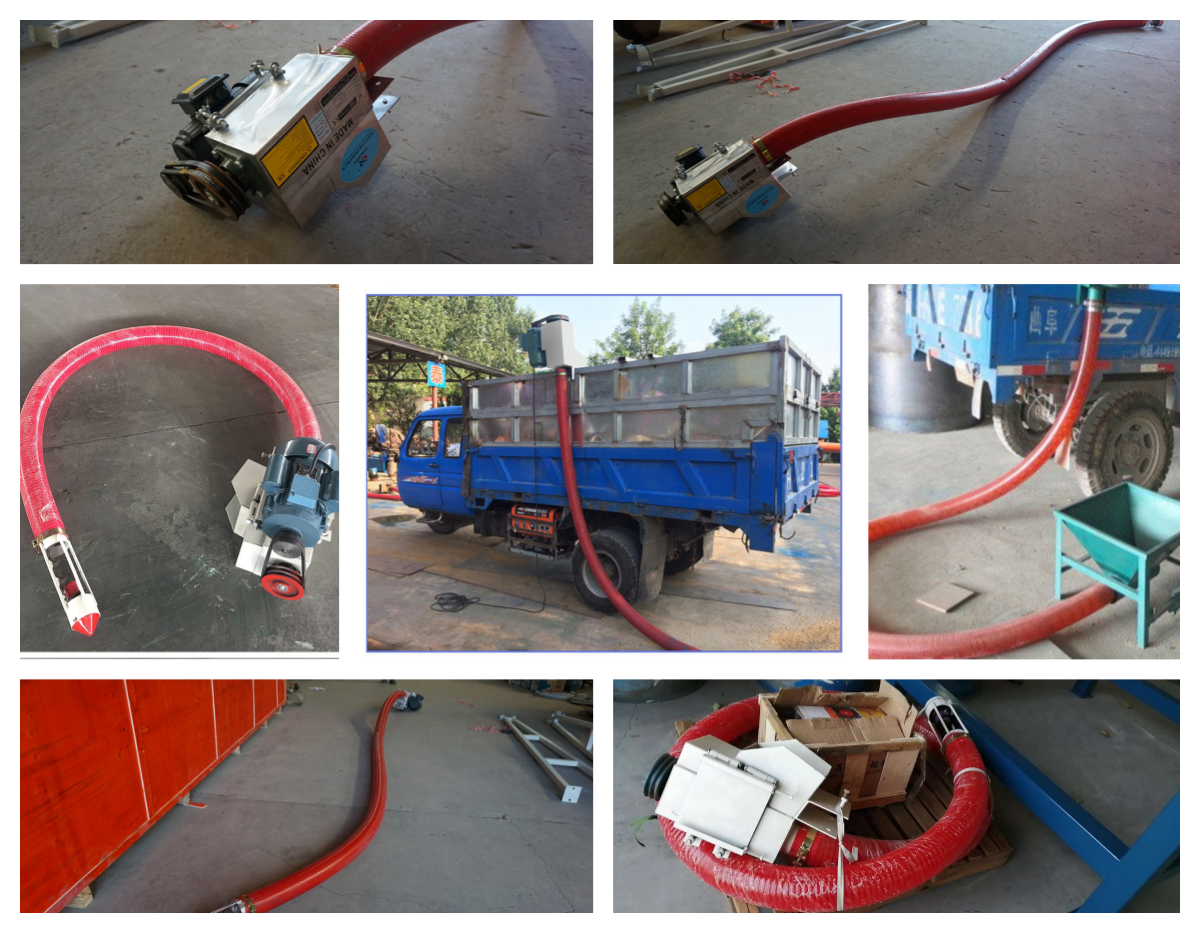

Application of portable vehicle mounted flexible screw conveyor

Grain storage and transportation in grain silos: The space in the silo is narrow, and the fixed conveyor cannot flexibly adjust the angle. The flexible screw can be bent and extended into the depth of the grain pile, and with the multi-angle adjustment bracket, horizontal-vertical integrated transportation can be achieved. The modular design is adapted to different silo heights (vertical transportation height can reach 8 meters).

Loading and unloading of bulk containers: The flexible screw can be bent and extended into the interior of the container, directly docking with the truck cargo box to achieve automated loading and unloading (efficiency of 20 tons/hour). The fully enclosed pipeline prevents dust leakage, meets the port's environmental protection requirements, and the daily loading and unloading volume can be increased to 500 tons, reducing labor costs by 70%.

Rapid loading of grains in the field: Traditional manual loading is inefficient, dusty, and the connection between the combine harvester and the transport vehicle is not smooth. The portable vehicle mounted flexible screw conveyor directly connects to the harvester discharge port to seamlessly transport grains to the truck cargo box, reducing the loss of throwing and spilling, and the daily loading volume can be increased from 80 tons to 300 tons.

Short-distance transportation of mineral powder: Temporary stockpiling points in open-pit mines are scattered, and the deployment cost of fixed conveyor belts is high. The on-board equipment moves with the mine car and directly connects to the mine car discharge port to transport the mineral powder to the processing area or temporary yard. Wear-resistant spiral blades (tungsten carbide coating) are used to deal with highly abrasive mineral powder.

Portable vehicle mounted flexible screw conveyor solves the problem of the inability to move and poor adaptability of traditional fixed screw conveyors through modular design and flexible conveying technology. It is especially suitable for small-scale operation scenarios that require flexibility. When selecting a model, you need to focus on material properties, vehicle compatibility, and environmental tolerance to ensure efficient and stable operation. "Simply summarize