Portable grain sucker for resin pellets

Tuesday March-11 2025 17:07:42

Portable grain sucker for resin pellets is used for conveying granular materials such as resin pellets. It is a lightweight and flexible negative pressure airflow conveying equipment, usually used in the agricultural field. It is mainly designed to suck and convey granular materials such as grain (such as wheat, corn, rice, etc.), and plays an important role in the field of material conveying.

Video of portable grain sucker for resin pellets

How does the portable grain sucker for resin pellets work?

Portable grain sucker mainly uses negative pressure airflow for material conveying.

The negative pressure is generated by the fan, and the airflow is formed at the suction port to suck the granular material into the pipeline.

Driven by the airflow, the material is transported to the designated position along the pipeline.

At the discharge end, the material is separated from the airflow to complete the conveying process.

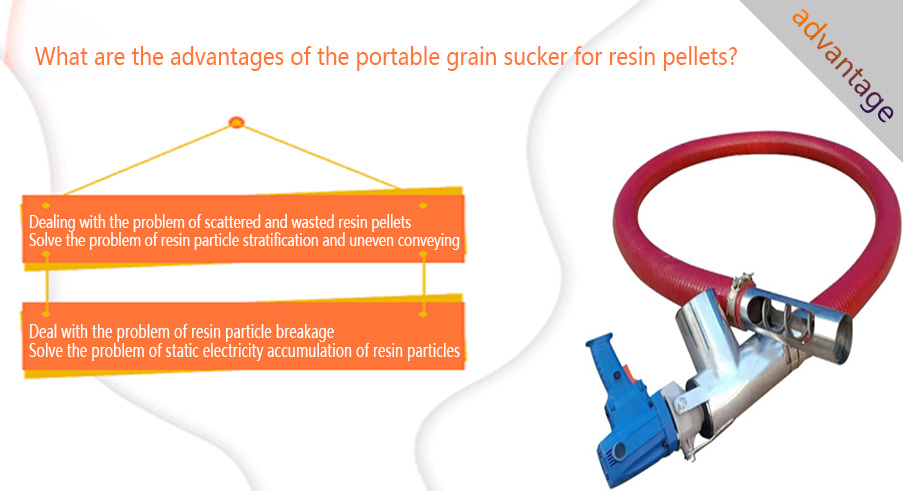

What are the advantages of the portable grain sucker for resin pellets?

1. Dealing with the problem of scattered and wasted resin pellets: Resin pellets are easily scattered on the ground or the surface of the equipment during the conveying process, resulting in waste and difficulty in cleaning. Through the negative pressure suction function, the portable grain sucker for resin pellets can quickly clean and recover the scattered particles and reduce waste.

2. Solve the problem of resin particle stratification and uneven conveying: Resin particles are prone to stratification during conveying, resulting in uneven conveying. Through negative pressure airflow conveying, portable grain sucker for resin particles can effectively reduce the stratification of resin particles and ensure uniform conveying of resin particles.

3. Deal with the problem of resin particle breakage: Resin particles may be broken due to collision or friction during conveying, affecting product quality. Portable grain sucker is used for resin particles to adjust the air flow speed and pressure to avoid severe impact on resin particles.

4. Solve the problem of static electricity accumulation of resin particles: Resin particles rub against the pipeline during high-speed conveying, which is easy to generate static electricity, causing the particles to be adsorbed on the pipeline wall. Portable grain sucker for resin particles uses anti-static plastic pipes or metal grounded pipes to reduce static electricity accumulation.

Portable grain sucker for resin pellets size range

|

Resin type |

particle size (mm) |

corresponding mesh number (approximately) |

recommended conveying method |

|

Ordinary resin granules (PP, PE, ABS, PC, etc.) |

2~5mm |

4~10 mesh |

negative pressure positive pressure pneumatic conveying |

|

Small particle resin (POM, EVA, TPU, etc.) |

0.5~2mm |

10~35 mesh |

vacuum conveying screw conveying |

|

Micro powder resin (PET powder, PA powder, etc.) |

<0.5mm |

35 mesh or above |

need to be closed negative pressure conveying to prevent dust diffusion |

|

Large particles or modified resin (filled masterbatch, long fiber reinforced plastic) |

5~8mm |

4 mesh or less |

high flow positive pressure conveying |

Common particle size and mesh number comparison of portable grain sucker for resin granules

1. Conventional resin granules (PP, PE, ABS, PC, etc.):

①The diameter is 2~5mm (general resin size), The mesh number is converted to about 4~10 meshes

②Recommended conveying method: pneumatic conveying or vacuum suction machine

2. Small particle resin (such as cast grade, extrusion grade resin):

①The diameter is 0.5~2mm, and the mesh number is converted to about 10~35 meshes

②Recommended conveying method is vacuum suction machine (static electricity accumulation must be prevented)

3. Micro-particle or powdered resin (such as filler masterbatch, nylon powder):

①The diameter is less than 500μm (0.5mm), and the mesh number is converted to more than 35 meshes

②Recommended conveying method: high-efficiency negative pressure pneumatic conveying (avoid dust leakage)

Analysis of the applicability of portable grain sucker for resin particles

Particle size and fluidity: The size of resin particles is usually between 0.3 and 1.2 mm, and most of them are in the range of 0.4 to 0.6 mm. They have good fluidity and regular bead shape. The suction design of portable grain suction machine can usually adapt to particle materials in this size range.

Suction and conveying capacity: Resin pellets are light (density is usually lower than grain), so the suction force of the portable grain sucker for resin pellets may need to be adjusted to avoid excessive airflow causing pellet blockage or equipment overload.

Material compatibility: Resin pellets may be chemically active, so it is necessary to ensure that the material used by the portable grain sucker for resin pellets can withstand long-term use.

Application of portable grain sucker for resin pellets

1. Raw material transportation in small plastic product processing plants: Resin pellets are usually stored in ton bags or small bags. The portable grain suction machine can directly suck the pellets out of the ton bag and convey them to the hopper of the injection molding machine or extruder.

2. Experimental production in laboratories or R&D departments: Small batches and multiple varieties of resin pellets are required for testing in the laboratory. Portable grain suckers can flexibly convey different types of resin pellets (to experimental equipment) by replacing pipes or adjusting suction.

3. Automation assistance for resin pellet packaging lines: After the production of resin pellets is completed, they need to be transported from the production equipment to the packaging machine for bagging or canning. Portable grain suckers can be installed in the packaging workshop to suck the pellets from the temporary storage silo and convey them to the automatic packaging equipment.

4. Short-distance transfer in resin pellet storage management: In the storage of resin pellets, it is often necessary to transfer pellets from one storage point to another. Portable grain suckers can suck and convey pellets to the target location through their flexible pipeline layout.

5. Material replenishment for emergency or temporary production lines: During peak production periods or when equipment failures cause temporary adjustments to production lines, portable grain suckers can be used as emergency tools.

Portable grain sucker for resin pellets have the advantages of flexibility, efficiency, precision and environmental protection when handling resin pellets. They are suitable for a variety of application scenarios such as the transportation of resin pellets, providing convenience and support for the production and processing of related industries.