Potato chip transport Z-type bucket elevator

Monday March-17 2025 16:25:43

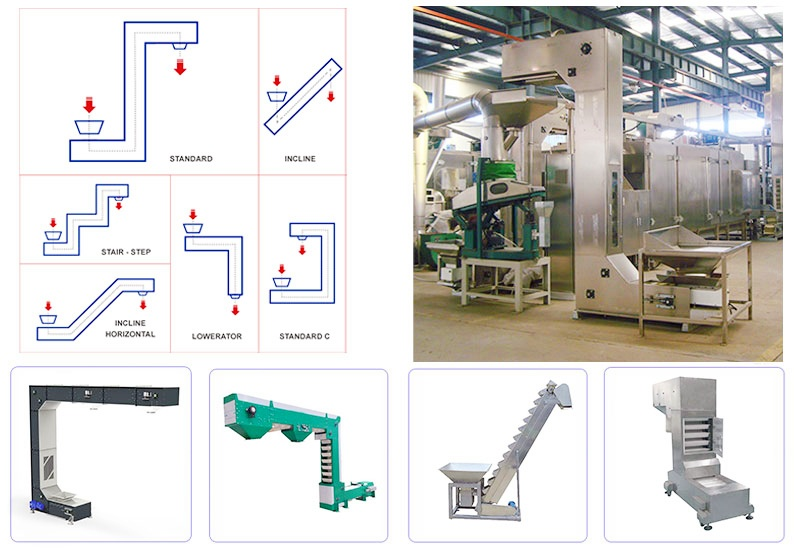

Potato chip transport Z-type bucket elevator is a device specially used for vertical or inclined conveying of light and fragile materials such as potato chips. It adopts a Z-shaped structure design, which allows materials to be efficiently conveyed between multiple horizontal and vertical sections, and can reduce the damage of potato chips during the lifting process. It is suitable for food processing plants, packaging workshops and other scenes.

Video of potato chip transport Z-type bucket elevator

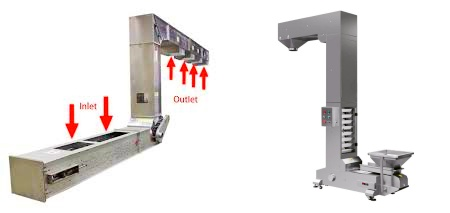

How does the potato chip transport Z-type bucket elevator work?

Potato chips enter the hopper from the feed port, are lifted to the top by the conveyor chain, and then turn down after passing the top wheel to pour the material into the receiving trough. The Z-type bucket elevator uses chain transmission, and the hopper is installed on the chain. The power drives the hopper to carry out four steps of receiving, lifting, dumping and returning, and repeats the cycle, thereby achieving the purpose of potato chips transportation.

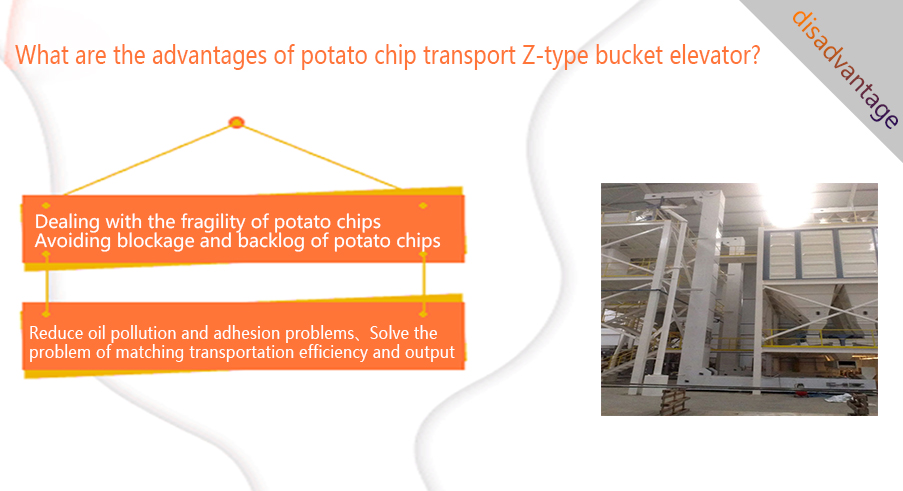

What are the advantages of potato chip transport Z-type bucket elevator?

1. Dealing with the fragility of potato chips: Potato chips are a light and fragile food that is easily broken by collision, friction or extrusion during transportation. The low-speed drive system and Z-type structure are used to reduce the vibration and impact of potato chips during transportation.

2. Avoiding blockage and backlog of potato chips: Potato chips are prone to blockage and backlog in traditional conveying equipment, affecting production efficiency. The bucket design and oblique upward conveying method of the Z-type bucket elevator for potato chip transportation can effectively avoid blockage and backlog and keep the conveying smooth.

3. Reduce oil pollution and adhesion problems: The surface of fried potato chips is greasey and easy to adhere to the equipment, and even affect the taste of subsequent batches of potato chips. The hopper and conveyor chain are made of oil-resistant materials (such as stainless steel) to reduce grease adhesion.

4. Solve the problem of matching transportation efficiency and output: The output of potato chip production lines varies greatly, and the transportation equipment needs to be seamlessly connected with the previous and next processes (such as frying) to avoid bottlenecks or overloads. The lifting speed and number of hoppers can be customized according to the output (such as 500kg-5 tons per hour).

Mesh count and design recommendations for potato chip transport Z-type bucket elevator

|

Parameters |

Recommended values |

Description |

|

Hopper opening size |

50-100mm (width) |

Suitable for regular potato chip sizes (about 30-80mm), avoiding stacking or jamming. |

|

Hopper capacity |

1.8L-4L |

Small capacity is suitable for the lightweight characteristics of potato chips to avoid overload crushing; can be adjusted according to production. |

|

Lifting speed |

5-15m/min |

Low speed operation reduces the collision and breakage of potato chips, and the specific speed is adjusted according to production and height. |

|

Chain/belt material |

Food grade PP or stainless steel chain |

Ensures durability and hygiene, PP chain is lighter and suitable for potato chip transportation. |

|

Tilt angle |

90° |

Vertical section angle in the Z-type path to ensure smooth transition and reduce potato chips from sliding. |

Application of potato chip transport Z-type bucket elevator

1. Potato chip production line

①Scenario description: On the potato chip production line, potato chips need to be transported from the production equipment to the packaging equipment or storage equipment.

②Application: Potato chip transport Z-type bucket elevator can be installed at different positions of the production line to transport potato chips from a low position to a high position, ensuring that the potato chips can enter the packaging equipment or storage equipment smoothly.

2. Potato chips warehouse management

①Scenario description: In the potato chips warehouse, potato chips need to be transported from the storage area to the loading area for loading and transportation.

②Application: Potato chip transport Z-type bucket elevator can be installed between different floors of the warehouse to lift potato chips from the storage area to the loading area for easy loading and transportation of potato chips.

3. Potato chips packaging and distribution

①Scenario description: In the process of potato chips packaging and distribution, potato chips need to be transported from the packaging equipment to the distribution equipment or storage equipment.

②Application: Potato chip transport Z-type bucket elevator can connect the packaging equipment and the distribution equipment or storage equipment to transport potato chips from the packaging equipment to the distribution equipment or storage equipment.

Notes on the potato chip transport Z-type bucket elevator

Choose the right bucket: Choose the right bucket according to the size and shape of the potato chips to ensure the stability and efficiency of the transportation.

Control the conveying speed: Control the conveying speed according to the fragility of the potato chips to reduce breakage.

Regular cleaning and maintenance: Regularly clean and maintain the Z-type bucket elevator for potato chip transportation to ensure the sanitation, safety and operating efficiency of the equipment.

Potato chip transport Z-type bucket elevator perfectly adapts to the needs of the food industry in potato chip transportation. Compared with the heavy material handling of the concrete batching screening machine, it pays more attention to the integrity and hygiene of lightweight materials. If you need more detailed design parameters or specific suggestions for a certain scenario, you can contact customer service or send an email, we can help you solve related problems and make a detailed quotation.