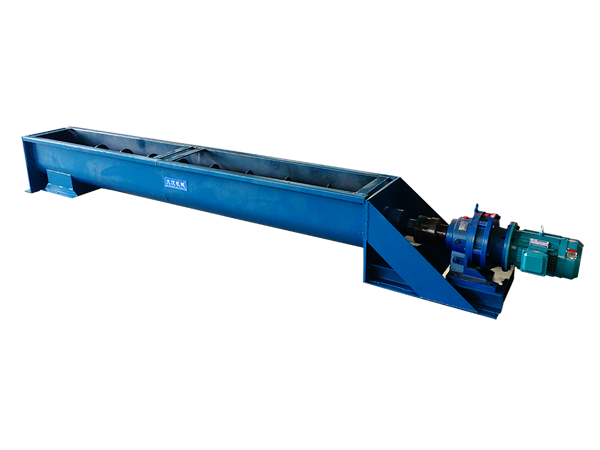

Precautions for U-Shaped Screw Conveyor

Wednesday February-08 2023 10:43:25

How to ensure the maximum service life of U-Shaped Screw Conveyor? For processing, choose a supplier that provides high-quality conveyors, choose the machine model that is most suitable for the materials you need to process, and also perform daily maintenance on the U-Shaped Screw Conveyor and pay attention to avoiding wrong operations during use. The following is U-Shaped Screw Conveyor needs to be aware of.

Before using U-Shaped Screw Conveyor:

1. Check the line:

Check if the line is intact

Check whether the line is normal

Check whether the line is safe

2. Check whether the machine is normal:

If any parts are loose or damaged, please repair by yourself or contact the purchaser for repair before use.

3. Soft start:

After checking that there is no problem with the machine, you can start the soft start. First, start the U-Shaped Screw Conveyor for no-load operation. It takes about 1-3 minutes. After there is no problem, you can start conveying materials.

4. Materials:

Before the material enters the U-Shaped Screw Conveyor, firstly, it needs to be fed at a uniform speed to avoid a large amount of feeding at one time. Second, it is necessary to pay attention to whether there are other sundries in the material for screening to avoid damage to the U-Shaped Screw Conveyor.

5. Status:

If the U-Shaped Screw Conveyor is running well, keep running the conveyor. If there is any abnormality in the operation of U-Shaped Screw Conveyor, you need to turn off the power first, and then check and repair after stopping.

6. After shutdown:

After completing the daily transportation work, it is necessary to ensure that there is no residual material in the machine before shutting down, and to clean the inside of the U-Shaped Screw Conveyor, and to inspect and lubricate the screw blades, casing, and driving device.