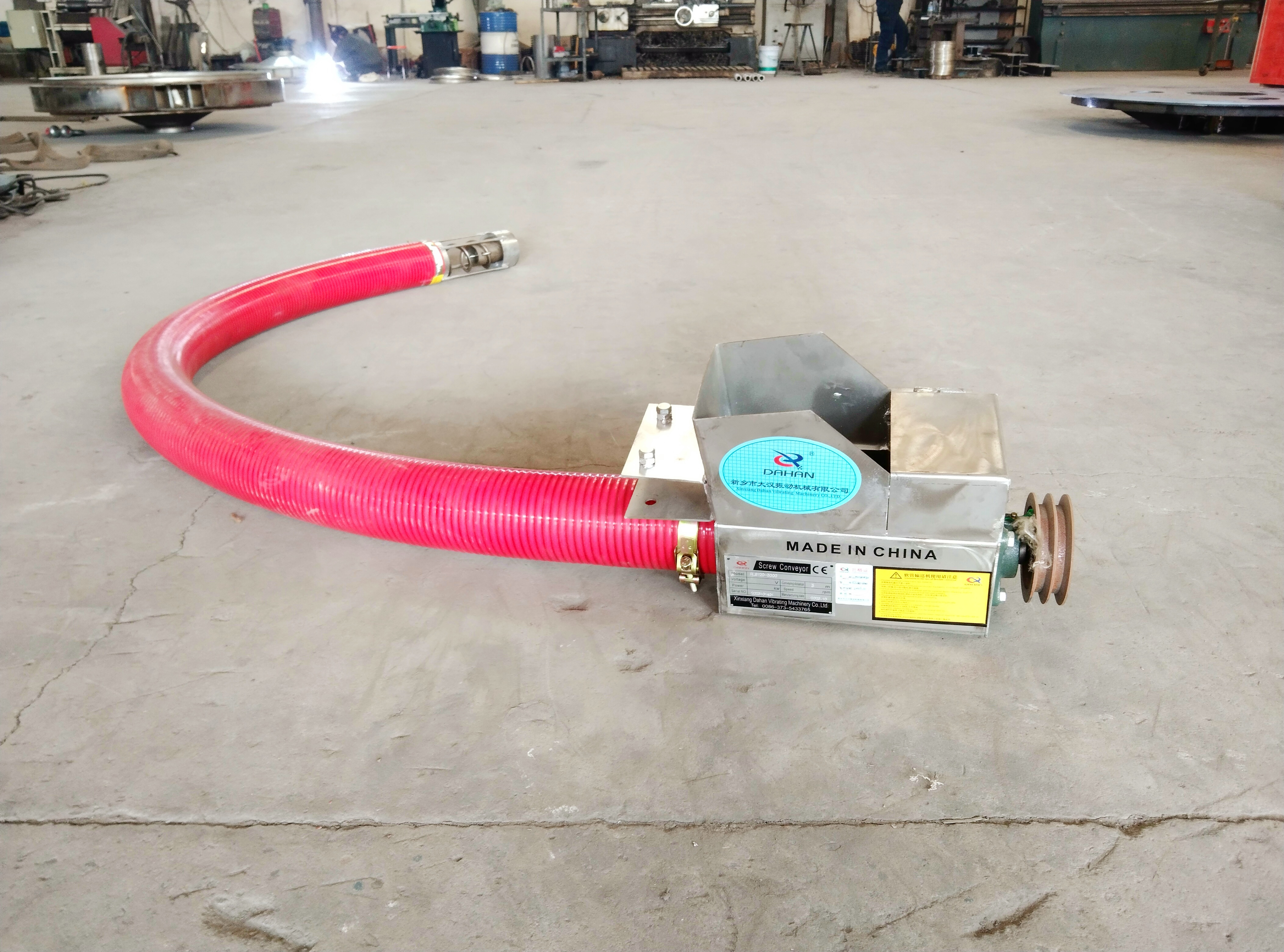

Quartz Sand Flexible Spiral Conveyor

Tuesday April-15 2025 16:35:37

Quartz sand flexible screw conveyor is a conveying equipment designed for powdery and granular materials such as quartz sand. It combines flexible conveying and screw propulsion technology and is suitable for horizontal, inclined or vertical material transportation. The quartz sand flexible screw conveyor is a mechanical equipment that uses the rotation of spiral blades to push materials along the conveying pipe. It is widely used in the transportation of quartz sand, cement, fly ash, grain, chemical raw materials and other materials.

Video of quartz sand flexible screw conveyor

What is the working principle of quartz sand flexible screw conveyor

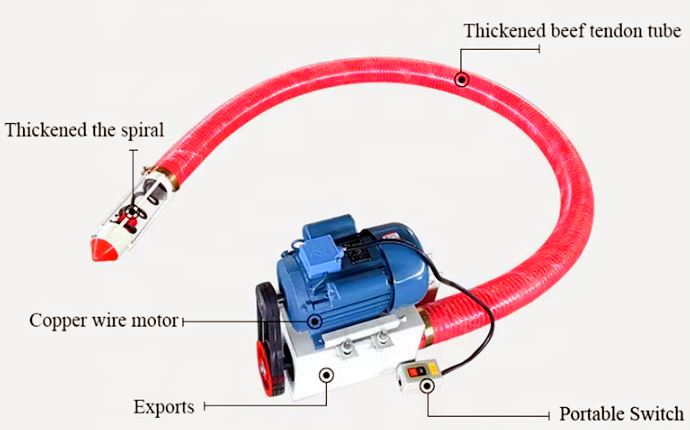

The working principle of the quartz sand flexible screw conveyor is to push the material forward through the rotation of the screw, but it is more flexible in structure and operation mode, and is suitable for occasions with curved paths or limited space.

Feed inlet: Quartz sand is fed into the conveyor at the feed inlet.

Rotating screw: The motor drives the flexible screw, which rotates in the conveying tube.

Material movement: The rotating screw pushes the quartz sand forward along the length of the tube. The design of the spiral blade determines the conveying rate and efficiency.

Discharge port: Quartz sand is discharged at the outlet of the conveyor.

What are the advantages of a quartz sand flexible screw conveyor?

Limited conveying capacity

Quartz sand flexible screw conveyor is suitable for small and medium-sized quartz sand conveying scenarios. If a large amount of quartz sand needs to be conveyed, multiple devices need to run at the same time, which will increase the equipment cost and floor space.

Limited conveying distance

The effective conveying distance of the quartz sand flexible screw conveyor is short. As the conveying distance increases, the friction between the quartz sand and the spiral blades and the conveying pipe wall will gradually increase, which will not only increase the energy consumption of the equipment, but may also increase the crushing rate of the quartz sand and affect the quality of the quartz sand.

Requirements for quartz sand particle size

Quartz sand flexible screw conveyor can convey quartz sand of different particle sizes, but for quartz sand with small particle size or dusty, dust is prone to occur during the conveying process. For quartz sand with larger particle size, the spacing of the spiral blades and the diameter of the conveying pipe may limit the conveying, resulting in poor conveying and even blocking the pipeline.

Relatively single material adaptability

Quartz sand flexible screw conveyor is mainly suitable for the conveying of granular and powdery materials such as quartz sand. For some sticky, wet or irregularly shaped materials, the conveying effect may be affected.

Technical specifications of quartz sand flexible screw conveyor

The following are common technical specifications of quartz sand flexible screw conveyor, and the specific parameters will vary depending on the design and application scenario:

|

Parameter |

Specification/Description |

Parameter |

Specification/Description |

|

Conveying capacity |

0.5–20 m3/h |

Screw diameter |

50–150 mm |

|

Transportation length |

1–15m |

Inclination angle |

0°–60° (horizontal, inclined or vertical pipeline requirements) |

|

Spiral material |

Spring steel, stainless steel |

Outer tube material |

Plastic flexible tube |

|

Motor power |

0.75–7.5 kW |

Variable frequency speed regulation |

100–600rpm |

|

Feed port size |

Customization |

Wear resistance |

Suitable for highly abrasive countertops such as quartz sand |

|

Working temperature |

-20°C to 80°C |

Safety device |

Overload protection, blocking sensor, emergency stop switch |

Advantages of quartz sand flexible screw conveyor compared with traditional conveying methods

|

Scenario |

Flexible screw conveyor solution |

Disadvantages of traditional methods |

|

Narrow workshop space |

Bendable to bypass obstacles (minimum bending radius 1.5m) |

Belt conveyor needs to be arranged in a straight line, occupying a large space |

|

Clean room environment |

Fully enclosed + negative pressure dust removal, dust concentration <1mg/m³ |

Pneumatic conveying has high energy consumption and fragile particles |

|

Multi-batch small flow conveying |

Precise speed control through inverter (±1rpm) |

Bucket elevator is difficult to adjust flow |

Application of quartz sand flexible screw conveyor

Quartz sand particles are usually dry and uniform in particle size, but because of their certain hardness and abrasiveness, they place high demands on equipment during transportation.

Glass manufacturing production line: In glass manufacturing plants, quartz sand needs to be conveyed from the raw material yard or silo pipeline to the batching system through a quartz sand flexible screw conveyor, mixed with other raw materials (such as soda ash) and then enter the furnace. The factory layout is usually continuous, and the pipeline path needs to bypass the equipment.

Foundry industry sand processing system: Foundries use quartz sand as raw material, and the dried quartz sand needs to be conveyed from the quartz sand flexible screw conveyor pipeline to the sand mixer or sand storage bin. Foundries are equipment-intensive, and the pipeline path may involve horizontal or even vertical directions.

Ceramic production raw material preparation: Ceramic factories use precision grinding wheels (particle size 0.05–0.3 mm) as blanks or glaze components, which need to be conveyed from screening and conveying equipment to ball machines or mixing and stirring equipment. Ceramic workshops are strictly controlled, and the pipeline equipment of quartz sand flexible screw conveyors needs to be sealed and easy to clean.

Photovoltaic silicon wafer production: The photovoltaic industry uses high-purity quartz sand to produce silicon wafers, and the selected quartz sand needs to be piped from the cleaning equipment to the purifier or reactor. The production environment has extremely high requirements for cleanliness, and the pipeline equipment needs to avoid replacement, and the humidity of the quartz sand may be higher.

Construction material production (such as mortar or concrete): Building material factories use quartz sand as aggregate for dry-mixed mortar or concrete. Quartz sand flexible screw conveyor can transport quartz sand from the stockpile to the mixing station or packaging line.

Quartz sand flexible spiral screw conveyor is flexible, wear-resistant and sealed, which is particularly suitable for quartz sand production lines and can effectively cope with the challenges of congestion, blocked materials and complex structures. Compared with traditional pipeline belts, it occupies a small area, is simple to maintain, and has a low height, making it an ideal choice for small and medium-sized quartz sand processing plants.