Rapeseed screw conveyor

Tuesday February-11 2025 18:43:33

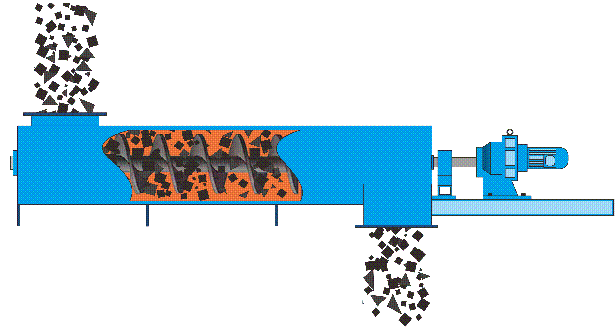

Rapeseed screw conveyor is a kind of equipment used to convey granular materials such as rapeseed. It conveys the materials along the conveying pipe or trough to the destination through the rotating motion of the spiral blade. Rapeseed screw conveyor is usually used in oil processing plants, food processing plants, grain processing plants and other places for the conveying and processing of granular materials such as rapeseed.

Rapeseed screw conveyor video

How does the rapeseed screw conveyor work

Rapeseed or other granular materials enter the conveying pipe or slot of the conveyor from the feed port of the conveyor. When the motor starts, the conveying shaft drives the spiral blade to start rotating and moving. The spiral shape of the spiral blade pushes the rapeseed forward during the conveying process and continuously conveys it to the discharge port along the conveying pipe or slot. Finally, it is conveyed to the designated location through the discharge port of the conveyor, completing the conveying process.

Advantages of rapeseed screw conveyor

1. Prevent rapeseed from breaking easily: the outer shell of rapeseed is hard, and the inner grain is soft, which is easy to break during the conveying process, affecting the oil yield. The spiral blades of the rapeseed spiral conveyor are usually made of wear-resistant materials and designed to be arc-shaped or streamlined to reduce friction and damage to the rapeseed and reduce the breakage rate.

2. Avoid the problem of rapeseed from agglomerating easily: the surface of rapeseed contains a certain amount of oil, which is easy to agglomerate in a high temperature and high humidity environment, causing conveying blockage. By adjusting the conveyor speed through the frequency converter, the conveying speed can be adjusted according to different conveying needs to avoid material agglomeration and blockage.

3. Prevent rapeseed dust from flying: rapeseed is prone to dust during transportation, polluting the environment and affecting the health of workers. The rapeseed spiral conveyor adopts a closed structure, which can effectively prevent the flying of rapeseed dust and improve the working environment.

4. Avoid rapeseed from generating static electricity easily: rapeseed is prone to generating static electricity during transportation, which may cause fire. Setting a grounding device on the conveyor can effectively eliminate static electricity and prevent fire.

Application of Rapeseed Screw Conveyor

Oil mill: Used to convey rapeseed from the storage area to the oil press.

Feed mill: Used to convey rapeseed to crushers, mixers and other equipment.

Biofuel production: Used to convey rapeseed to biodiesel production equipment.

Recommended mesh size for rapeseed

Characteristics of rapeseed: The particle size of rapeseed is generally 1.5-2.5 mm. When screening, you should choose a mesh size that matches it.

Recommended mesh size:

8-12 mesh: If it is mainly used for transportation and there are fewer impurities, you can choose a 8-12 mesh screen, which is suitable for preliminary screening to remove larger impurities (such as straw, stones, etc.).16-20 mesh: If fine screening is required, it is recommended to choose a 16-20 mesh screen to remove smaller impurities (such as sand, debris, etc.).

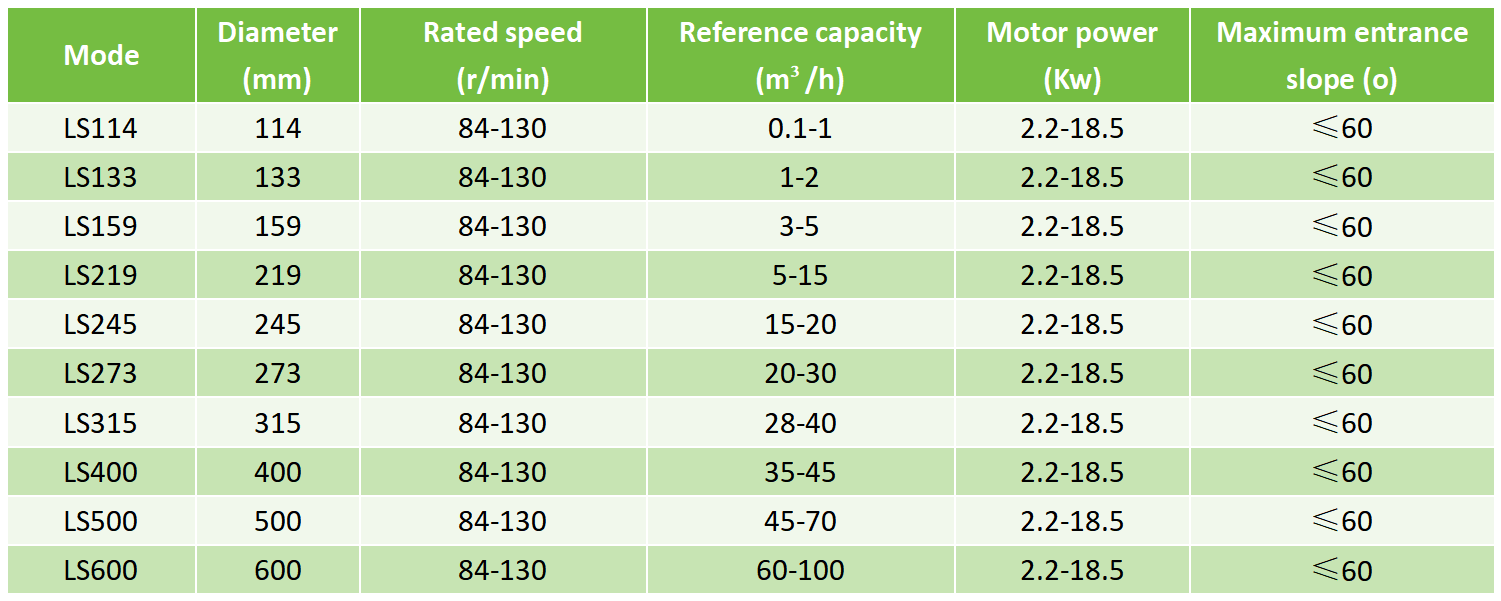

Technical parameters of rapeseed screw conveyor

Precautions for choosing a rapeseed screw conveyor

1. Preparation before conveying: Before starting, check the motor, reducer, spiral blades, bearings and other parts to ensure that there is no looseness, wear or foreign matter. Lubricate the bearings, reducers and other parts regularly to reduce wear. Perform a no-load test run before starting to confirm that there are no abnormal conditions such as abnormal noise and vibration.

2. Conveying process control: Avoid sudden large-scale feeding to prevent blockage or motor overload. Adjust the speed according to the conveying volume to avoid too fast to cause crushing or too slow to affect efficiency. Pay attention to the motor current, temperature and equipment operating status, and stop the machine for inspection in time if any abnormality is found.

3. Safety protection: Ensure that safety devices such as protective covers and emergency stop switches are intact. It is forbidden to touch rotating parts during operation. Be sure to turn off the power when cleaning or repairing. Open flames are strictly prohibited on site, and fire extinguishing equipment is equipped.

4. Rapeseed characteristics Rapeseed is easy to absorb moisture. Pay attention to moisture-proof and avoid agglomeration during transportation. Control the conveying speed to reduce crushing. Clean the equipment regularly to prevent clogging by impurities.

Select a manufacturer of rapeseed screw conveyor

Rapeseed screw conveyor is a reliable conveying equipment that provides convenience and efficiency for the transportation of rapeseed. It is widely used in agriculture, food processing and oil production. Selecting a suitable screw conveyor and maintaining it regularly can ensure its long-term stable operation and improve production efficiency.