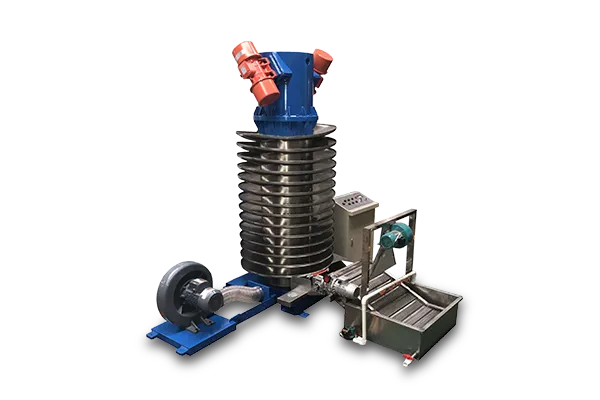

Salt Air Cooling Vibrating Spiral Conveyor

Monday January-20 2025 16:00:32

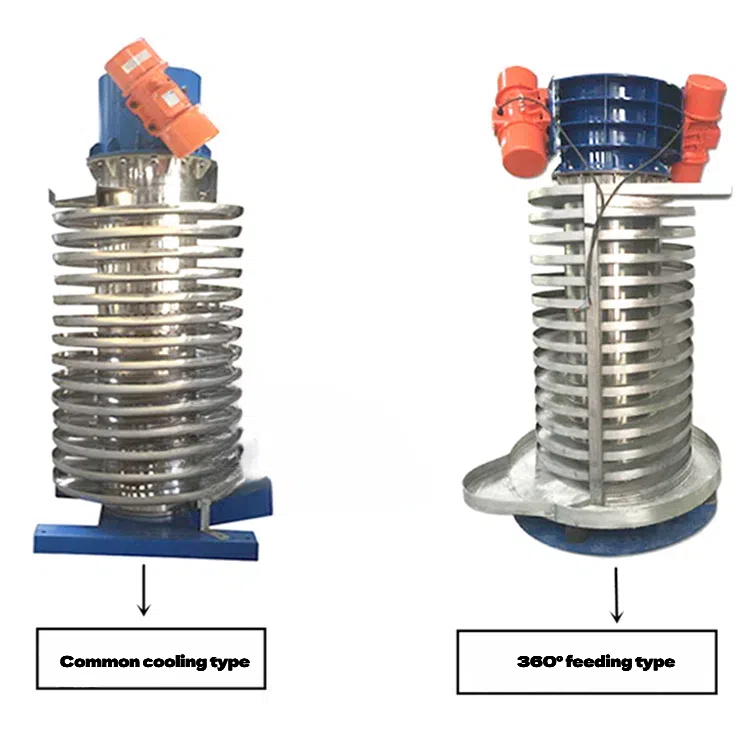

Salt air cooling vibrating spiral conveyor is a type of equipment designed for conveying salt or similar materials through a vibrating spiral mechanism while incorporating air cooling functionality to lower the temperature of the conveyed salt. This equipment is commonly used in industries where salt processing or handling requires both continuous transportation and cooling to maintain product quality and integrity.

Working principle of salt air cooling vibrating spiral conveyor

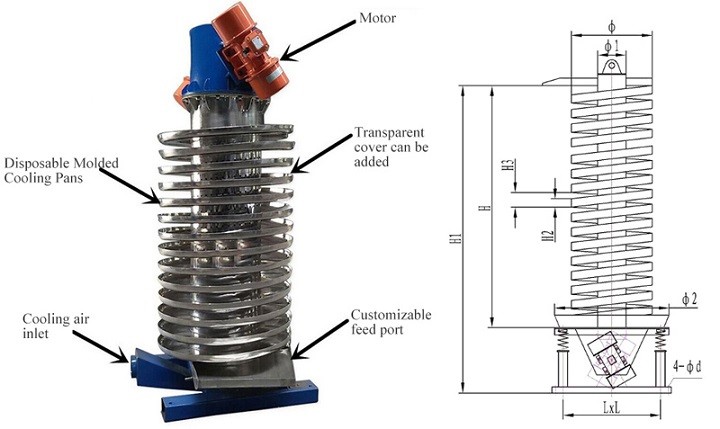

Feeding stage: Salt is fed into the feed port of the vertical vibrating elevator at a certain speed and amount.

Vibration conveying: Once the salt enters the elevator, the vibration mechanism starts to operate, and the salt is conveyed upward along the spiral device through vibration.

Fan cooling: During the conveying process, the fan is started, and the air flows through the salt material through the ventilation and cooling device to reduce the temperature of the salt.

Vertical lifting: The salt is conveyed vertically upward to the target position under the action of vibration and spiral.

Discharging: After reaching the target height, the salt is released from the discharge port of the elevator and can continue to be used for subsequent processing or packaging.

Application of salt air cooling vibrating spiral conveyor

Salt air cooling vibrating spiral conveyor can effectively transport and cool salt vertically, meet the needs of different industries for salt transportation and temperature control, improve production efficiency and ensure product quality.

Food processing industry: used for salt transportation and cooling to ensure the quality and temperature control of salt during food processing.

Chemical industry: used for vertical transportation of salt or salt chemicals, and control product temperature through fan cooling.

Salt making plant: used for vertical transportation and cooling of salt to meet the requirements of salt temperature in the salt making process.

Salt packaging production line: used to transport salt from the ground to the packaging machine during the salt packaging process, and cool it through the fan to ensure the appropriate temperature of the salt during packaging.

Salt processing plant: used for internal transportation and cooling of salt, such as when the salt needs to be temperature controlled during the salt processing process.

Advantages of salt air cooling vibrating spiral conveyor

Temperature control: Salt is prone to moisture absorption and agglomeration during transportation. The design with a fan can effectively reduce the temperature of the salt and prevent moisture and agglomeration caused by temperature rise.

Prevent agglomeration: Through continuous vibration and cooling, the fluidity of salt particles can be maintained, and the adhesion and agglomeration of materials during transportation can be reduced.

Reduce material loss: By controlling temperature and humidity, the loss of salt during transportation can be reduced, ensuring the consistency and quality of the final product.

Reduce breakage: It can achieve gentle material transportation, reduce the impact on salt particles, and reduce the risk of breakage.

Key considerations for salt air cooling vibrating spiral conveyor

Corrosion Resistance: Salt is highly corrosive, so the conveyor must be constructed from materials resistant to salt and moisture, such as stainless steel.

Hygiene: In food processing applications, strict hygiene standards must be maintained. The conveyor should be easy to clean and sanitize.

Material Flow: Salt can be abrasive, so the conveyor components must be designed to withstand wear and tear.

Cooling Efficiency: The cooling system must be designed to effectively cool the salt to the desired temperature.

Salt air cooling vibrating spiral conveyor effectively prevents salt from breaking through temperature control, appropriate vibration characteristics and design optimization, ensuring that the quality and integrity of the salt is maintained during the transportation process.