Sand And Gravel Suction Machine

Wednesday April-02 2025 14:24:59

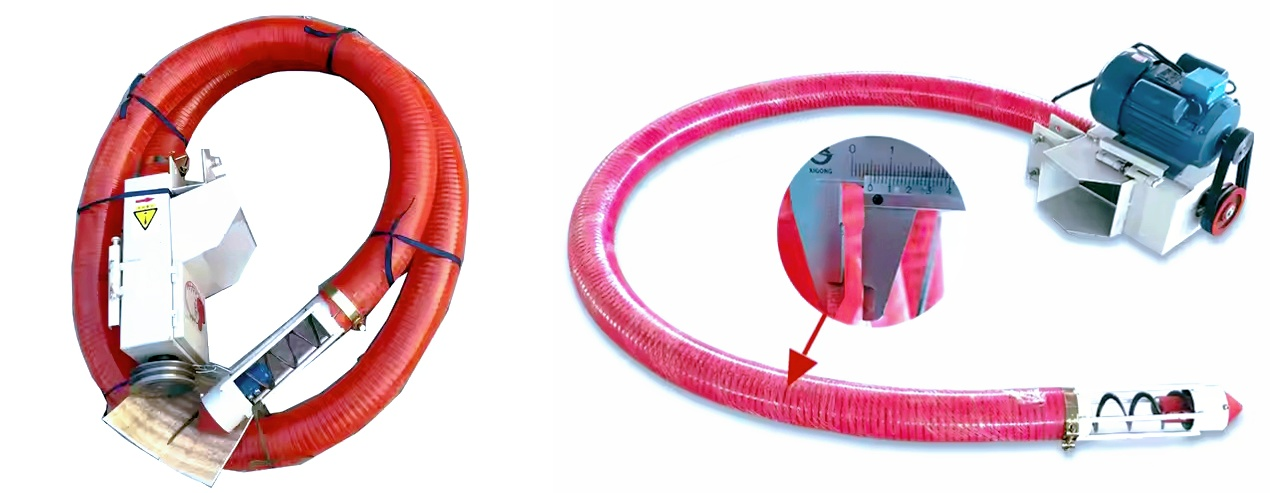

Sand and gravel suction machine is a kind of equipment used to extract and transport solid-liquid mixtures such as sand and gravel, cement slurry, slag, etc. It is widely used in river dredging, mine transportation, construction engineering, concrete construction and other fields. The equipment uses high negative pressure suction or pumping system to mix sand and gravel with water or other media and then suck them from one place to a designated location, improving work efficiency and reducing labor costs.

Video of sand and gravel suction machine

How does the sand and gravel suction machine work?

Suction process: Sand and gravel suction machine and gravel suction machine drives the pump body through the power system to generate strong suction. The suction pipe penetrates into the sand and gravel layer and sucks the sand and gravel together with the water.

Transportation process: The sucked sand and gravel mixture is transported to the target location such as a stockpile, transport ship or separation equipment through a pipeline.

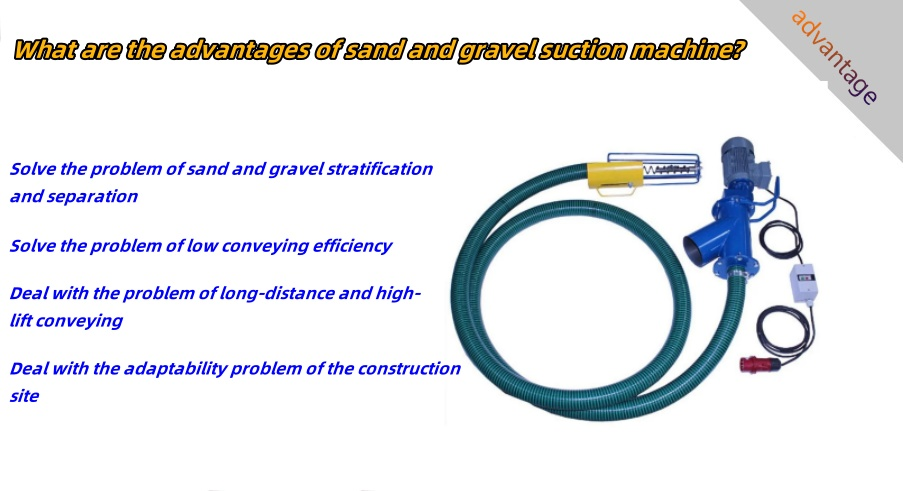

What are the advantages of sand and gravel suction machine?

1. Solve the problem of sand and gravel stratification and separation: During long-distance transportation, coarse sand and fine sand may be stratified due to density differences, affecting uniform transportation. Adjust the conveying speed and pressure of the sand and gravel suction machine to keep the material flow uniform and prevent particle stratification.

2. Solve the problem of low conveying efficiency: Sand and gravel with high water content are easy to adhere to the inner wall of the pipe, forming deposits, affecting the conveying efficiency. Sand and gravel suction machine uses large-diameter wear-resistant pipes to reduce the number and angle of bends and avoid blockage points.

3. Deal with the problem of long-distance and high-lift conveying: The longer sand and gravel conveying distance, the greater the power loss and the obvious attenuation of flow rate. When conveying at high lift, materials are prone to backflow or accumulation. For ultra-long-distance conveying, sand and gravel suction machine adds a multi-stage conveying system.

4. Deal with the adaptability problem of the construction site: The construction site environment is complex, there may be a lack of stable power supply, or the rugged terrain is not conducive to the movement of equipment. Sand and gravel suction machine can be selected as vehicle-mounted, crawler-mounted or ship-mounted to adapt to different terrains.

Technical parameters of sand and gravel suction machine

|

Parameter category |

Technical parameter range |

Parameter category |

Technical parameter range |

|

Conveying capacity |

10-500 m³/h |

Conveying distance |

10-300m (depending on the machine model and working conditions) |

|

Conveying height |

5-50m (customizable) |

Applicable particle size |

0-50mm (different models are suitable for different particle sizes) |

|

Suction pressure |

-0.08~-0.1MPa (vacuum type) |

Pumping pressure |

1.0-3.5MPa (hydraulic or mechanical pump type) |

|

Power mode |

electric/diesel/hydraulic drive |

Power range |

5-150kW (depending on the conveying volume and working conditions) |

|

Conveying medium |

sand, cement slurry, mud, slag, etc. |

Pipeline material |

wear-resistant alloy steel/rubber hose/polyurethane |

|

Equipment type |

vacuum negative pressure、mortar pump、hydraulic sand and gravel suction machine |

Applicable environment |

land, river, mine, construction, etc. |

Application of sand and gravel suction machine

1. Construction field

In high-rise building construction, sand and gravel suction machines can transport concrete mortar from the ground to high-rise buildings, avoiding manual handling and improving construction efficiency. In underground engineering construction, the equipment can transport mortar and backfill materials, reducing the difficulty of traditional manual filling.

2. River dredging and water conservancy projects

In reservoir, lake and river management, gravel suction machines can extract silt and river sand, which helps to keep the waters unobstructed. For the sediment deposition problem of port terminals, the equipment can be used for regular cleaning to ensure the smooth flow of waterways.

3. Mining and sand mining industry

Sand and gravel suction machines can be used for ore transportation in mines, and the original ore or tailings slurry after ore dressing can be transported to designated locations. In the process of river sand and sea sand mining, suction machines can efficiently transport sand and gravel to reduce damage to the riverbed.

4. Ocean and port engineering

Sand and gravel suction machines can be used for coastal restoration, transporting seabed sand and gravel to seawalls, beaches and other areas for reinforcement. In the construction of large ports, it can transport filling materials such as sea sand and gravel to improve the efficiency of land reclamation.

5. Agriculture and ecological restoration

Sand and gravel suction machines can be used to transport sand and fertilizer to improve the efficiency of land improvement. In wetland restoration projects, it can be used for the migration and filling of sediments. In desertification control projects, the equipment can transport specific soil materials to help fix quicksand.

Comparison between sand and gravel suction machine and traditional equipment

|

Scenario |

Traditional method |

Sand and gravel suction machine solution |

Effect comparison |

|

River channel desilting |

Dredger excavation, truck transfer |

Sand and gravel suction machine directly sucks silt and gravel, and transports them to the yard through pipelines |

Efficiency increased by 3 times, cost reduced by 40% |

|

Sand mining site |

Forklift loading, belt conveyor transportation |

Sand and gravel suction machine underwater suction + screening, automatic loading |

Reduce labor, sand and gravel purity increased by 20% |

|

Tailing recovery |

Manual screening, low efficiency |

Sand and gravel suction machine sucks tailings sand, cyclone extracts metal particles |

Recovery rate increased from 50% to 85% |

|

Construction foundation pit drainage |

Submersible pump drainage, manual cleaning after sand and gravel sedimentation |

Sand and gravel suction machine sucks mud and sand mixture, directly separates sand and gravel from sewage |

Save 90% cleaning time |

If you have specific questions, such as wanting to know the parameters, selection suggestions or actual cases of a certain sand and gravel suction machine, you can contact our customer service, and we will provide more detailed answers!