Sand suction machine

Saturday April-19 2025 17:27:47

What is a sand suction machine?

Sand suction machine is a mechanical device that uses power to generate negative pressure. It uses the suction conveying principle to efficiently and directionally collect and transfer sand (including but not limited to river sand, sea sand, construction sand, etc.) scattered in a specific area to a designated location, taking into account the characteristics of sand that is easy to flow, fine particles, moderate specific gravity and loose state.

Its core function is to overcome the low efficiency and environmental limitations of traditional manual or mechanical shoveling of sand, and realize the long-distance transportation and recovery of sand.

What are the types of sand suction machines?

1.Classification by working principle

|

Type |

working principle |

applicable scenarios |

sand characteristics adaptation |

|

Vacuum sand suction machine |

negative pressure suction (vacuum pump + closed pipe) |

fine sand recovery in construction pit, dust cleaning in workshop |

dry sand, powdered sand (particle size ≤ 2mm) |

|

Centrifugal pump sand suction ship |

centrifugal force sand throwing (impeller high-speed rotation) |

river sand mining, seabed sand mining |

wet sand, muddy sand (anti-clogging design required) |

|

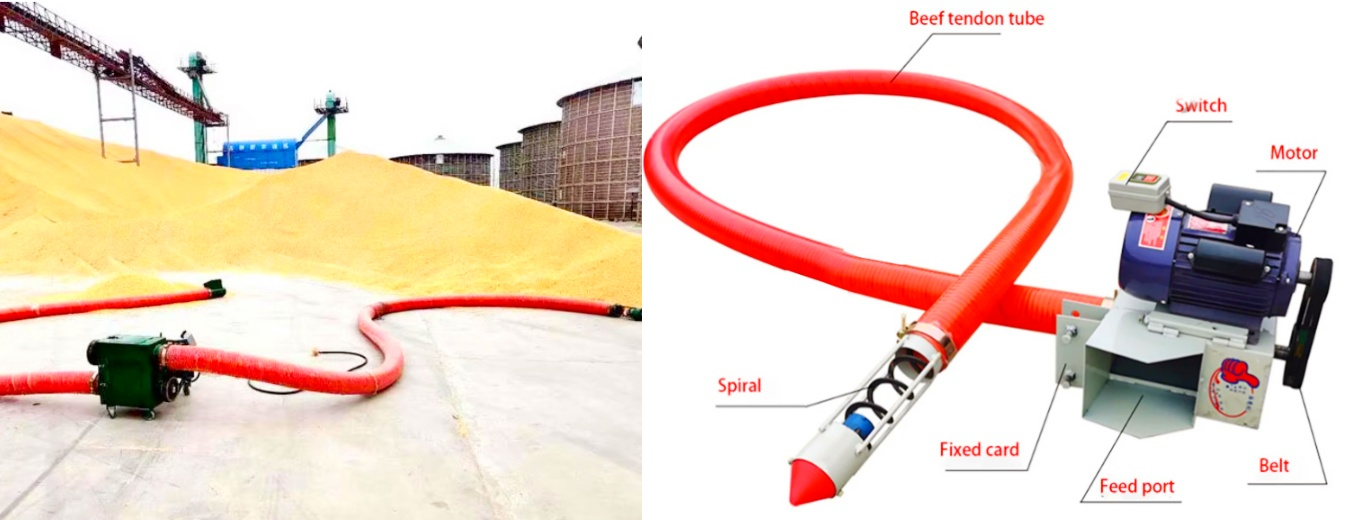

Spiral sand suction machine |

spiral blade mechanical push |

sewage treatment plant sand settling tank, industrial sand silo |

high water content sand (anti-caking) |

2. Classification by movement mode

Fixed type: used in sand and gravel processing plants (such as sand production line matching).

Crawler/tire type: suitable for scenes that require frequent transfers such as sand mining sites and construction sites.

What is the working principle of the sand suction machine?

Sand suction machine rotates at high speed through a fan or vacuum pump, forming a negative pressure area near the sand suction port. The outside air flows to the suction port under the action of the pressure difference, carrying sand to form a gas-solid two-phase flow. The high-speed airflow brings the sand into the sand suction pipe through the "entrainment effect". The sand particles move in the pipe in a suspended or jumping state (the air flow speed must be controlled ≥ the "suspension speed" of the sand particles to avoid deposition and blockage). The airflow carries the sand through the pipe to the specified location.

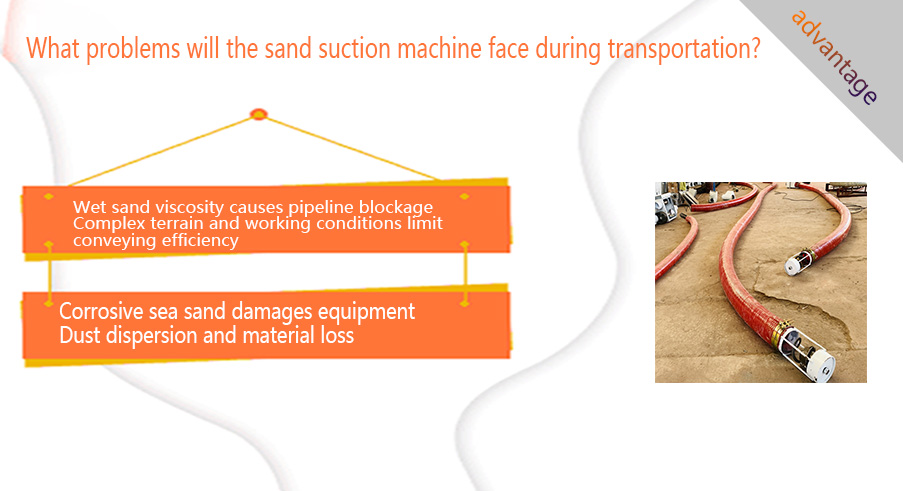

What problems will the sand suction machine face during transportation?

Wet sand viscosity causes pipeline blockage

Problem: Wet sand or sand containing mud (commonly found in riverbeds and seabeds) is sticky and easily accumulates in the sand suction pipe or pump, causing blockage and reducing the conveying efficiency.

Solution: The sand suction pump impeller of the sand suction machine adopts a wide flow channel (channel width 50-100mm) to reduce sand accumulation, separate sand from mud and water, and keep the pipeline unobstructed.

Complex terrain and working conditions limit conveying efficiency

Problem: The terrain of sand transportation scenarios (such as underwater riverbeds, deep seas, and remote deserts) is complex, and the sand suction depth (5-30 m) and transportation distance (50-2000m) are high, which ordinary equipment cannot cope with.

Solution: The sand suction pipe, pump body and impeller of the sand suction machine are made of high chromium alloy, stainless steel or ceramic coating, with a wear-resistant life of 1-3 years. The sand suction pipe is designed in an arc shape to reduce direct impact of sand; the impeller adopts a wide flow channel to reduce the wear rate.

Corrosive sea sand damages equipment

Problem: Sea sand contains salt and organic matter, which is corrosive. Long-term contact may cause the sand suction pipe, pump body or storage tank to rust, reducing the life of the equipment.

Solution: The pump body and sand suction pipe of the sand suction machine are made of 316L stainless steel or anti-corrosion coating (such as epoxy resin), mechanical seal or corrosion-resistant packing seal to prevent salt water from penetrating into the bearing.

Dust dispersion and material loss

Problem: Fine sand (particle size <0.5 mm) is easy to generate dust during suction and transportation, causing material loss, environmental pollution or dust accumulation inside the equipment, affecting operating efficiency.

Solution: The sand suction machine uses a fully enclosed storage tank (capacity 0.5-5m³) to reduce dust leakage. High-efficiency filter (pore size 0.01-0.1mm) or bag dust collector (filtration efficiency 99%) captures fine sand dust and recycles materials.

Application of sand suction machine

Sand suction machinee sucks sand (dry sand, wet sand or sand containing silt) through negative pressure or centrifugal force and transports it to the target location through pipelines. It is widely used in the following scenarios

River dredging and waterway desilting:

The water depth of rivers, lakes or port waterways is reduced due to siltation, affecting shipping or flood control capabilities. Sand suction machine is used to suck sand (particle size 0.5-2mm, often containing mud and gravel) from the riverbed or lake bottom and restore the siltation of Xiangjiang River.

Sand mining operation (supply of construction materials):

Sand (fine sand 0.1-0.5mm, medium sand 0.5-1mm) from riverbeds, lakes or deserts is sucked and used to produce concrete, mortar or glass raw materials. Portable or fixed sand suction machine sucks dry or wet sand and transports it to the yard or truck.

Land reclamation and land reclamation:

Sand from the seabed or near the shore (particle size 0.5-1mm, containing salt and organic matter) is sucked for land reclamation or land reclamation to expand the land area or repair the eroded area. Portable sand suction machine sucks sea sand and transports it to the eroded area. The cyclone or screen separates salt and shell fragments. Corrosion-resistant pump body and conductive sand suction pipe prevent static electricity and salt corrosion

Tidal flat restoration and coastal protection

The coastline is lost due to erosion, and it is necessary to suck seabed or near-shore sand (particle size 0.5-1mm) to replenish the tidal flat and protect the coastal ecology or tourism resources. Portable sand suction machine sucks seabed sand, separates salt water and mud through the cyclone, and transports it to the reclamation area. Wear-resistant sand suction pipe and anti-corrosion coating extend the life of the equipment.

Mining and tailings treatment

The tailings sand (particle size 0.1-1mm, containing mineral particles) or sand mining by-products produced by mining need to be sucked and transported to recover useful sand or treat waste. The fixed sand suction machine sucks the tailings sand and transports it to the recovery pool or yard. The filter removes fine dust and the conductive sand suction pipe prevents static sparks.

The physical properties of sand (such as particle size, composition, and hardness) directly determine the design parameters of the sand suction machine. The sand suction machine effectively solves the problems of fluidity, wear and separation of sand in engineering applications through negative pressure transportation, material recovery and environmental adaptability design.