Screw Conveyor Belt For Transferring

Thursday April-10 2025 15:30:15

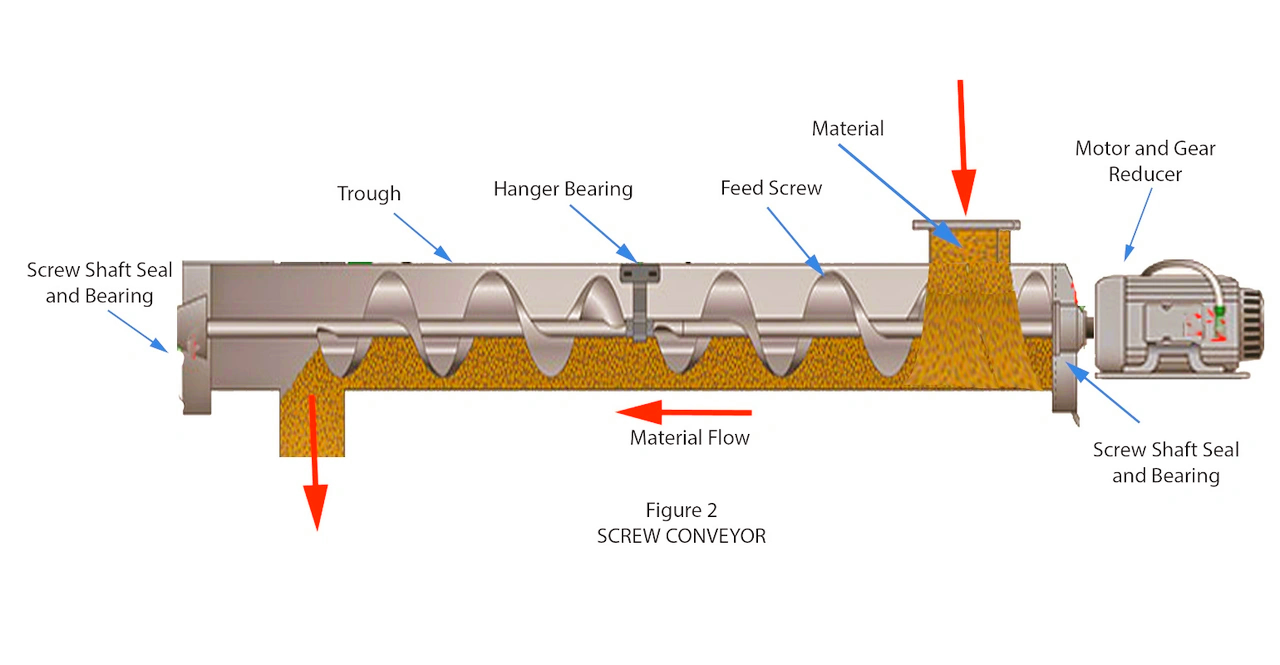

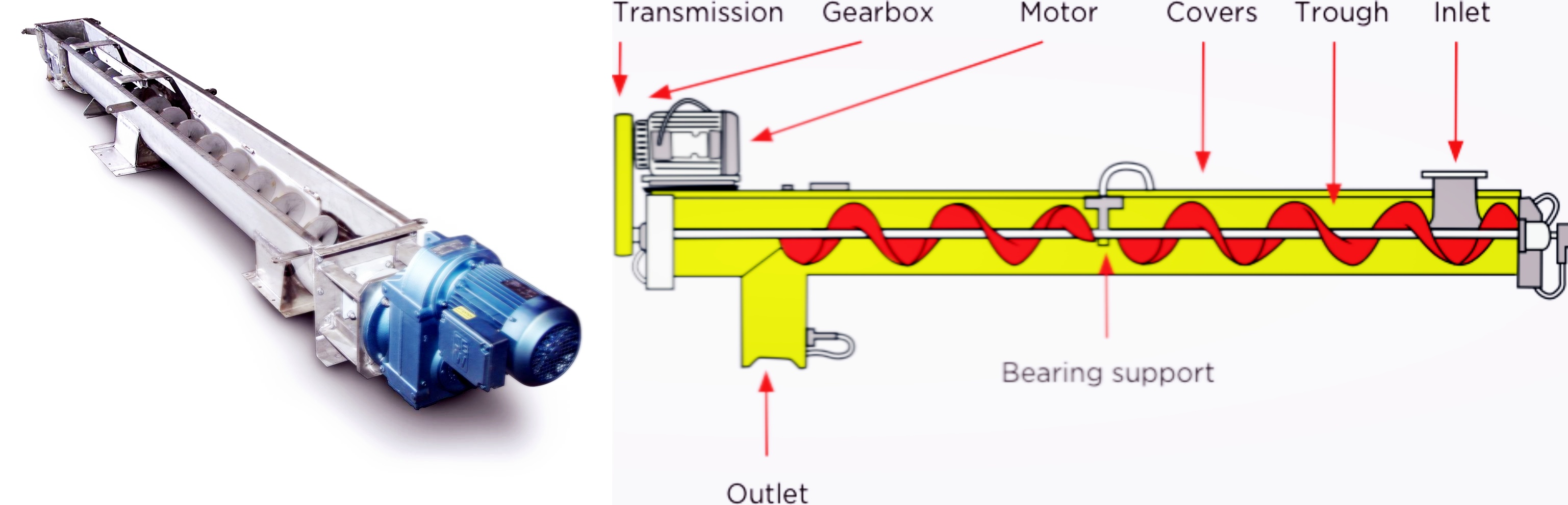

Screw conveyor belt for transferring is a mechanical device that utilizes a helical screw blade attached to a central shaft to move materials along a trough or tube. This type of conveyor is designed to efficiently transport a wide variety of bulk materials, including powders, granules, and small pieces, from one location to another within industrial processes.

How does the screw conveyor belt for transferring work?

Screw conveyor belt for transferring operates on the principle of rotation. The motor drives the central shaft on which the screw blade is mounted. As the screw rotates, it pushes the material forward along the length of the conveyor trough. The pitch of the screw blade, along with the speed of rotation, determines the rate at which the material is transported. Materials are fed into one end of the conveyor and discharged at the other end, enabling continuous and controlled transfer.

What are the advantages of screw conveyor belt for transferring?

Conveying in limited space: Some production lines or process layouts have limited space, and traditional equipment is difficult to install or arrange. Screw conveyor belt for transferring has a compact structure and small footprint. It can flexibly carry out horizontal, inclined or even vertical conveying to meet the needs of narrow spaces.

Quantitative or controllable conveying is required: Some processes require precise control of the material conveying volume. By controlling the speed of screw conveyor belt for transferring, the material conveying volume can be effectively adjusted, providing a relatively stable conveying rate, which is suitable for batching, metering and other links.

Conveying sticky materials: Some sticky materials tend to adhere to the belt conveyor, resulting in reduced conveying efficiency and difficulty in cleaning. The special design of the spiral blades of screw conveyor belt for transferring can better push the sticky material forward and reduce adhesion.

Need to feed or discharge at multiple points: Some production processes require adding materials to the conveyor at different locations, or unloading at different locations. Screw conveyor belt for transferring can meet the needs of multi-point feeding and discharging by setting multiple feed ports and middle or end discharge ports.

Technical Specifications of Screw Conveyor Belt For Transferring

Diameter: 6-12 inches (15-30 cm), screw conveyor belt for transferring is suitable for typical industrial use.

Capacity: 1-50 tons/hour, depending on material density and screw speed (e.g., 20-100 RPM).

Power: The motor power of screw conveyor belts for transferring is 1–15kW, depending on length and load.

Length: Screw conveyor belts for transferring can be customized, usually 3-15 meters per section.

Related parameters of Screw Conveyor Belt For Transferring

|

Parameter name |

Description/range |

Remarks |

|

Transportation type |

Horizontal, inclined, vertical |

The horizontal of screw conveyor belt for transferring is used for translation, and the inclined (<45°) and vertical (>45°) are used for lifting |

|

Screw speed |

20–150 RPM (revolutions per minute) |

Screw conveyor belt for transferring low speed is used for sticky materials, and high speed is used for materials with good fluidity |

|

Pitch |

50–600 mm (usually 0.5–1 times the diameter) |

The larger the pitch, the higher the pipeline efficiency, but the higher the requirement for unloading fluidity |

|

Material |

Carbon steel, stainless steel (304/316L) |

Stainless steel is used for food/screw conveyor belt for transferring is suitable for chemical industry, corrosion-resistant; carbon steel is used for general industry |

|

Trough/tube form |

U-shaped groove, round tube |

The round tube of screw conveyor belt for transferring is suitable for closed pipelines (such as import control) |

|

Feed port size |

200×200 mm to 500×500 mm (customizable) |

Designed according to the order input device (such as hopper) of screw conveyor belt for transferring |

|

Number of discharge ports |

1–multiple |

screw conveyor belt for transferring can set multiple discharge points along the pipeline path |

|

Tilt angle |

0°–90° |

0° is horizontal, 90° is vertical, the larger the angle, the lower the pipeline efficiency |

|

Anti-blocking design |

Shaftless design, non-stick coating, vibration assistance |

Shaftless screw conveyor belt for transferring is suitable for sticky, coating reduces |

What are screw conveyors belt for transferring used for?

Screw conveyor belts for transferring are primarily used for bulk material handling in a variety of industries. These machines are designed to efficiently transport granular, powdered or small pieces of material such as grain, cereals, coal, cement, sand, fertilizers and waste products along horizontal, inclined or vertical paths.

Maintenance considerations for screw conveyor belt for transferring

Regular inspection of spiral blades

Screw conveyor belts for transferring are prone to wear, especially when handling abrasive materials. The blades should be inspected regularly for signs of wear, such as thinning or damage to the blade edges. If severe wear is found, the blades may need to be repaired or replaced.

Lubrication of moving parts

The bearings and other moving parts of screw conveyor belts for transferring need to be lubricated regularly to ensure smooth operation and reduce friction. Please follow the manufacturer's recommendations on lubrication type and frequency.

Cleaning of the conveyor trough

Screw conveyor belts for transferring needs to be cleaned regularly to prevent material accumulation, avoid blockage and affect the performance of the conveyor, especially when handling sticky or agglomerated materials.

If you need specific equipment selection suggestions, site layout diagrams or system integration solutions for a certain material, Dahan Machinery can effectively solve your problems. You can consult us via email or customer service.