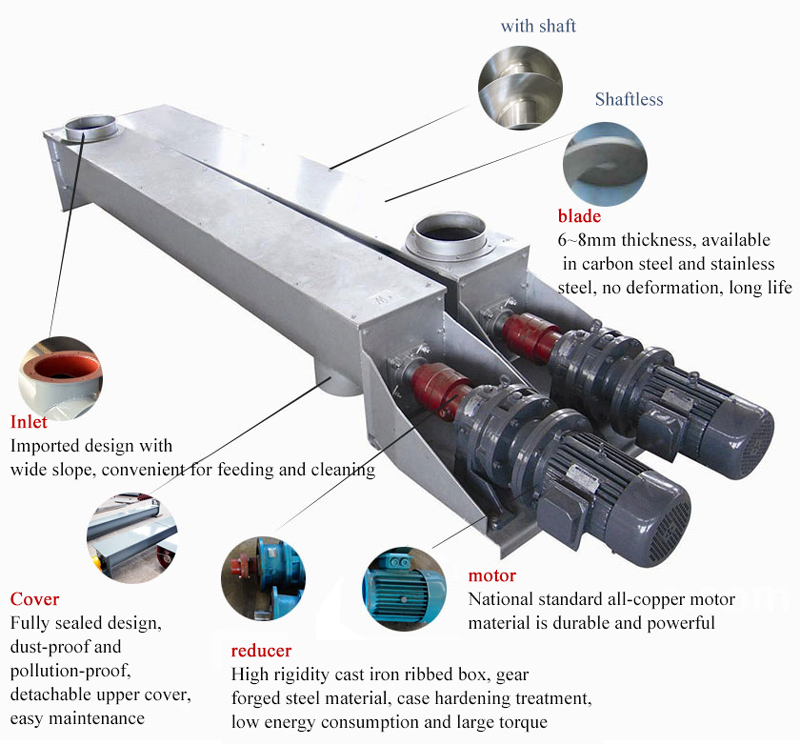

Screw conveyor structure

Friday April-01 2022 10:34:46

The screw conveyor is mainly composed of a driving device, a casing, a cover plate, a screw shaft, a screw blade, a feeding port, a discharging port and other structures.

1. Drive device

The driving device of the screw conveyor includes three parts: the motor, the reducer and the coupling. The motor is responsible for driving, the reducer prevents the screw shaft from rotating too fast and causes damage to the conveyor, and the coupling is responsible for transmitting the power to the screw shaft.

2. Spiral blade

Helical blades can be mainly divided into three categories: solid helical surface, ribbon helical surface and paddle helical surface.

Solid helical surface: simple structure, strong conveying capacity, suitable for conveying dry granular or powdery materials with good scatter, and is the most widely used blade type.

Belt helical surface: the helical pitch is the same as the diameter of the helical blade, which is suitable for conveying powdery and small pieces of material.

Paddle-type helical surface: mainly used to transport materials with high viscosity and compressibility. This kind of screw blade has and completes the functions of mixing and mixing materials at the same time in the process of completing the transportation operation.

3. Chassis

It can be divided into "U"-shaped casing and circular casing. The circular casing is mainly used for feeding the sealing equipment. The screw conveyor of the U-shaped casing is recommended to transport materials horizontally (the casing is not sealed).

4. Screw shaft

Made of hollow steel tube, a short length of solid shaft is used at the shaft-to-shaft connection and where the bearings are mounted. The solid shaft has a smaller diameter and can be plugged into a hollow steel tube for connection. If the material is easy to be wound, you can choose a shaftless conveyor.