Shaftless Screw Conveyor for Dewatered Sludge

Thursday July-27 2023 12:25:26

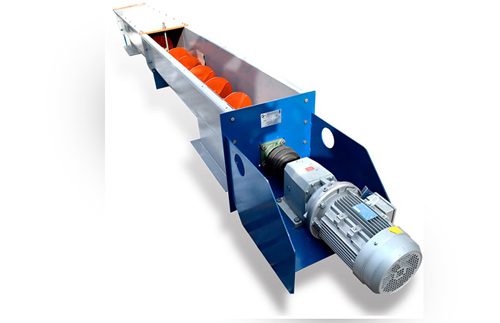

Introduction of Shaftless Screw Conveyor for Dewatered Sludge

Shaftless screw conveyor for dewatered sludge is used for the handling and conveying of dewatered sludge, sludge from municipal sewage treatment processes, residential sewage pretreatment plants or livestock waste applications such as manure systems, providing a non-clogging conveying surface that eliminates sludge and slurry buildup and ensures hassle-free material handling. Fully enclosed to prevent any material from escaping, tank lids with proper gaskets allow for odor-free operation and create a barrier to prevent any atmospheric media from entering the system.

Composition Structure of Shaftless Screw Conveyor for Dewatered Sludge

Shaftless screw conveyor for dewatered sludge is mainly composed of a driving device, a head assembly, a casing, a shaftless screw body, a tank liner, an inlet, an outlet, a cover (if necessary), a base, etc.

1. Driving device: Cycloidal pin wheel reducer or shaft-mounted hard-toothed gear reducer is used. When designing, the driving device should be installed at the end of the discharge port as much as possible, so that the spiral body is in a tensioned state during operation.

2. Case: The case is U-shaped, with a rain-proof cover on the top, made of stainless steel or carbon steel.

3. Shaftless helix: the material is stainless steel or carbon steel.

4. Lining plate of tank body: the material is wear-resistant plastic plate or rubber plate or cast stone plate, etc.

Working Principle of Shaftless Screw Conveyor for Dewatered Sludge

When the sludge is discharged to the feed port on the U-shaped groove, the sludge is discharged from the outlet at the bottom of the U-shaped groove through screw drive. The sludge is like a fixed nut when working, and the shaftless screw is like a rotating bolt. The continuous rotation of the bolt can drive one end of the nut to the other end. The horizontally installed shaftless screw conveyor can use two filter presses and a centrifuge to simultaneously collect the treated sludge and transport it to the next process.

Benefits of Shaftless Screw Conveyor for Dewatered Sludge

The advantages of the shaftless screw conveyor for dewatered sludge mainly include the following points:

1. Shaftless design: This design can avoid problems such as bearing wear and oil leakage that may occur in traditional screw conveyors, and improves the reliability and service life of the equipment.

2. Large processing capacity: Shaftless screw conveyor for dewatered sludge can carry out continuous transportation according to the needs, and its conveying capacity can be adjusted according to the requirements of users.

3. High efficiency and energy saving: The equipment uses a motor as a power source, has high conveying efficiency, and can automatically adjust according to the moisture content of the sludge, so as to achieve the purpose of energy saving.

4. Simple structure: the equipment has no complex transmission device, relatively simple structure and easy maintenance.

Application of Shaftless Screw Conveyor for Dewatered Sludge

Shaftless screw conveyor for dewatered sludge is widely used in sewage treatment plants, paper mills, chemical plants and other scenes that need to deal with sludge. It can transport the dewatered sludge from the dewatering machine or other sludge treatment equipment to the storage bin or transport vehicle, so as to facilitate subsequent treatment or transportation.

Shaftless Screw Conveyor for Dewatered Sludge Selection Notes

1. Conveying products and output: In fact, sludge is also classified into wet and dry. For sludge materials with different attributes, the selected screw conveyors are also different. Relatively dry sludge has higher requirements on sealing, which can prevent dust from appearing in the transportation process, while wet sludge has relatively strong entanglement, so the design is also different. Different conveying volumes correspond to different models. The larger the output, the larger the selected sludge screw conveyor model.

2. Conveying speed: In general, the speed should not be too fast to prevent the increase of dynamic load.

3. User requirements: The particle size of the selected sludge screw conveyor is different under different models, so it is necessary to select the corresponding model of equipment according to the material particle size required by the user.