Stainless Steel Hand Help Sucker Machine

Saturday April-19 2025 17:27:53

What is a stainless steel hand help sucker machine?

Stainless steel hand help sucker machine is a portable sand suction device made of stainless steel (usually 304 or 316L stainless steel), designed for small-scale, highly flexible sand handling tasks. It generates negative pressure (0.1-0.5bar) through a small vacuum pump or centrifugal pump, sucks sand (particle size 0.0625-2mm) from the ground, underwater or accumulation area, and transports it to a collection container or target location through a short-distance pipeline (5-50 m).

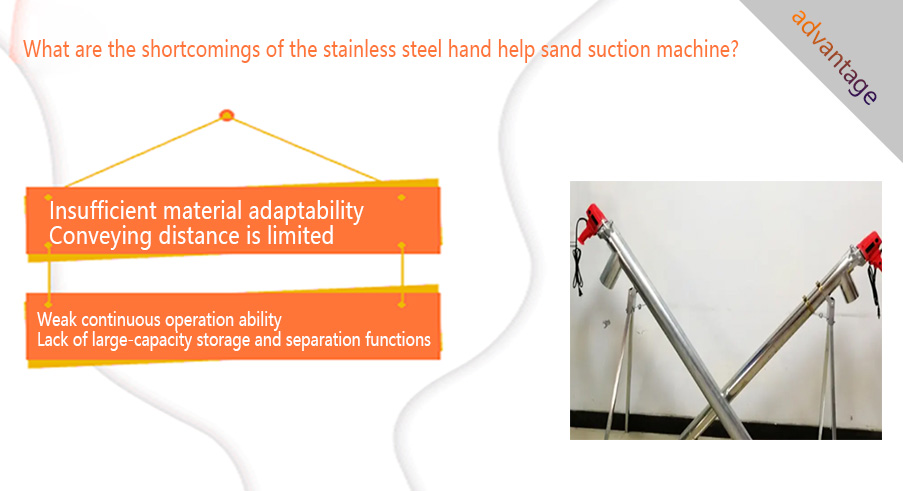

What are the shortcomings of the stainless steel hand help sand suction machine?

Insufficient material adaptability: It cannot handle light materials (such as grains, plastic particles, etc.). Because the negative pressure design of the sand suction machine is aimed at high-density sand, light materials are easily over-sucked and cause pipeline blockage.

Conveying distance is limited: The stainless steel hand help sand suction machine has low power and limited suction. It can only absorb a small amount of sand at a time. The efficiency is much lower than that of the grain suction machine, and it cannot meet the transportation needs of large quantities of sand.

Weak continuous operation ability: Due to power and volume limitations, the hand help sand suction machine is more suitable for short-term, small-scale cleaning or collection work. Long-term continuous operation may cause overheating or reduced efficiency.

Lack of large-capacity storage and separation functions: Hand help sand suction machines usually only have a small dust collection bin or require manual dumping, lacking large-capacity storage and complex separation functions.

What is the structure of the stainless steel hand help sand suction machine?

The structure of stainless steel handheld sand suction machines is usually designed to be portable, easy to use, and durable enough to handle fine particles such as sand. Although the specific design may vary depending on the intended use, the core components generally include: suction nozzle/inlet, collection chamber/container, motor and impeller/pump mechanism, power supply, handle, and body shell. The structure of stainless steel handheld sand suction machines is relatively simple, focusing on generating local suction and collecting small amounts of sand.

Comparative advantages of stainless steel hand help sand suction machines and traditional sand suction tools

|

Comparison items |

stainless steel hand help sand suction machines |

ordinary plastic/iron sand suction tools |

|

Durability |

life ≥ 5 years (wear-resistant and rust-proof) |

plastic is easy to crack |

|

Hygiene |

can be disinfected, no pollution risk |

gaps hide dirt and are difficult to clean. |

|

Applicable sand |

dry/wet sand, corrosive sand, high-temperature sand |

ordinary dry sand only. |

|

Maintenance cost |

filter screen/impeller can be replaced separately, low long-term cost |

overall scrapping, frequent replacement |

Application of stainless steel hand help sand suction machine

Stainless steel hand help sand suction machine is used in some specific, small-scale and refined scenes due to its light, easy operation and corrosion resistance:

Geological soil sample collection and processing: Collect sand samples during field geological exploration, or process rock weathering, river sediment, etc. in the laboratory, and use stainless steel sand suction machine to absorb loose sand particles with a particle size of 0.05~2mm (such as desert sand, riverbed sand) to avoid particle stratification damage caused by traditional shoveling.

Local cleaning of small industrial equipment: During the maintenance of some precision instruments or small equipment, fine sand or similar particles may be scattered. The use of hand help sand suction machine can easily clean these local areas to avoid affecting the normal operation of the equipment.

Small laboratory application: In the laboratory, it may be necessary to collect or transfer a small amount of fine experimental sand, silica gel particles, or other similar granular materials. The hand help sand suction machine can accurately absorb the required amount, avoid direct contact, and facilitate experimental operation.

Glass crafts and hourglass filling: Make glass bottle sand paintings, fill hourglasses with sand, or repair broken sand art ornaments. When filling 0.2~0.8mm frosted glass sand, the sand suction speed is controlled by the flow regulating valve of the sand suction machine (0.1~1g/s) to ensure that the color boundaries of the multi-layer sand painting are clear and avoid color mixing caused by manual pouring.

Key technical specifications of stainless steel hand help sand suction machine

|

Parameters |

Specifications |

Remarks |

|

Material |

304/316L stainless steel, sand suction tube lined with conductive rubber or polyurethane coating |

corrosion-resistant (sea sand), wear-resistant (quartz), anti-static (dry sand). |

|

Weight |

5-20 kg |

Single-hand help, with shoulder strap or handle, strong portability. |

|

Power |

0.5-5kW |

Suitable for small operations, pneumatic type is suitable for power-free environment |

|

Sand suction tube |

Inner diameter 25-100mm, length 1-3 m, conductive rubber |

Anti-static, wear-resistant, suitable for dry and wet sand |

|

Suction depth |

0.5-5 m |

Suitable for shallow or ground sand suction |

|

Conveying distance |

5-50m |

Short-distance conveying, suitable for small scenes |

|

Conveying capacity |

0.1-2 tons/hour |

Small-scale operation, depending on sand particle size and power |

|

Storage tank capacity |

10-50 L |

Collect sand, equipped with drain valve |

|

Separation system |

cyclone (efficiency 85%) or filter (pore size 0.5-2 mm) |

Separate mud and water to prevent wet sand from clogging |

|

Antistatic performance |

Surface resistance <3×10⁸ Ω, ground resistance <4Ω |

Prevent static sparks from dry sand |

Stainless steel hand help sucker machine is a local suction conveying equipment designed for the characteristics of "high sand density, fast deposition, poor fluidity, and impurities". It integrates "wear resistance, corrosion resistance, flexibility, and lightness" and is widely used in sand discharge, sand cleaning, and mobile sand extraction scenes with limited space and precise requirements.