Structural characteristics of double screw conveyor

Tuesday March-08 2022 15:59:37

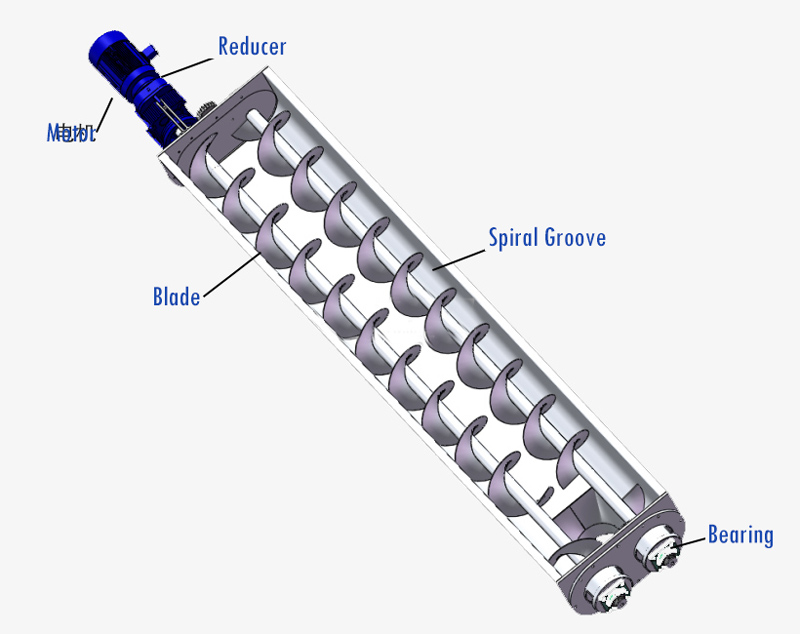

The double-screw conveyor uses two seamless steel pipes, each of which is equipped with a solid spiral, one of which is left-handed and the other is right-handed. What are the structural characteristics of the double-screw conveyor? The following is the relevant introduction:

1. Blade structure of double screw conveyor

There are three types of double helix blades: solid surface type, belt type surface type, blade surface type, etc. The materials that can be conveyed by different blades are also different. The helical surface is rarely used, and is mainly used for conveying materials with high viscosity and compressibility. During the conveying process, processes such as stirring and mixing are completed at the same time, and the helical pitch is about 1.2 times the diameter of the helical blade.

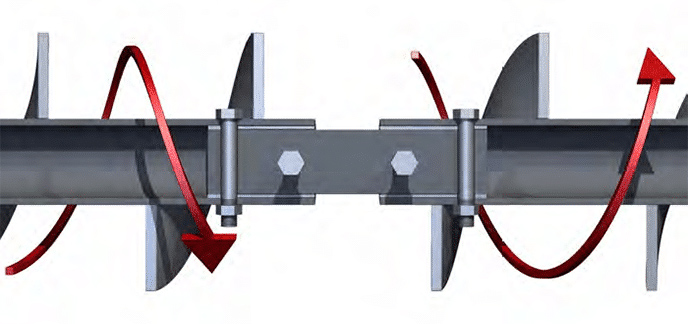

2. The rotation axis determines the material conveying direction

The direction of rotation of the rotating shaft of the double-screw conveyor determines the conveying direction of the material. Generally, the double-screw conveyor is designed with rotating blades designed for single-item conveying. When it is conveyed in reverse, the service life of the conveyor will be reduced.

3. Double shaft design increases the conveying capacity

Compared with the single-shaft screw conveyor, the double-screw conveyor has a higher helix angle than the single-screw blade at the same speed, so the conveying flow of the blade per unit time is larger, and the conveying volume has increased to the original single-screw blade. 1.5 to 2 times the helix.

Summary:

Compared with other conveying equipment, the double screw conveyor has the advantages of small cross-sectional size, good sealing performance, stable and reliable operation, multi-point loading and unloading in the middle, safe operation, and simple maintenance.