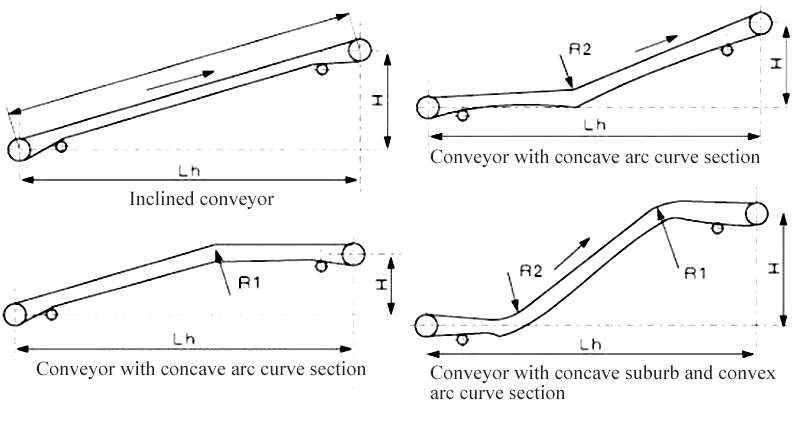

Structural features of inclined belt conveyor

Monday March-14 2022 15:46:18

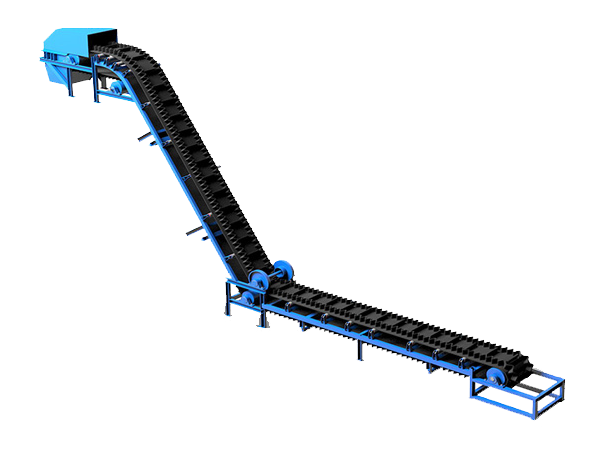

The inclined belt conveyor is referred to as the large inclination belt conveyor. It is mainly used to transport bulk materials at a large inclination or vertical 90°, and solve the conveying angle that cannot be achieved by ordinary and patterned belt conveyors. The oblique belt conveyor is in flat rubber. The two sides of the conveyor belt are glued with vertically stretchable rubber corrugated vertical "skirts", and between the skirts there are transverse partitions with certain strength and elasticity to form a box-shaped bucket, which can prevent materials from falling.

The structure and characteristics of the inclined belt conveyor:

1. Corrugated sidewall conveyor belt: it plays the role of traction and bearing in the conveyor. The corrugated rib, diaphragm and base belt form a "gate"-shaped container for conveying materials, thereby realizing large-angle conveying.

2. Driving device: It is the power part of the conveyor. It is composed of Y series motor, ZJ type shaft-mounted reducer and wedge type backstop.

3. Transmission drum: It is the main component of power transmission, and the conveyor belt runs by the friction between it and the transmission drum. This series of drive rollers has a rubber surface and a smooth surface. The rubber surface roller is to increase the adhesion between the roller and the conveyor belt.

4. Reversing roller: used to change the running direction of the conveyor belt. Diverting rollers are used on the lower surface (non-bearing surface) of the conveyor belt.

5. Pinch pulley: used to change the running direction of the conveyor belt, and the pinch pulley is used on the upper surface (bearing surface) of the conveyor belt.

6. Idler: Idler is used to support the conveyor belt and the materials on the belt to make it run stably. This series has two types of upper parallel idler and lower flat idler.

7. Belt support roller: The belt support roller is used to support the lower branch of the conveyor belt on the convex arc section frame, and it is supported on the empty edges on both sides of the sidewall conveyor belt. Several groups of belt rollers form an arc segment for redirecting the conveyor belt. The idler roller is supported by cantilever.

8. Vertical rollers: Vertical rollers are used to limit the deviation of the conveyor belt and are installed on the upper and lower transition frames. There are 4 filters on the frame of each filter segment, and the upper and lower parts are divided into two.

9. Beating wheel cleaning device: used to beat the back of the conveyor belt to shake off the materials stuck on the conveyor belt.

10. Tensioning device: its functions are as follows: 1. Make the conveyor belt have sufficient tension to ensure that the conveyor belt and the drive roller do not slip. 2. Limit the sag of the conveyor belt between the supports to make the conveyor run normally. This series adopts screw tensioning device.

11. Rack, head funnel, head shield, material guide trough, intermediate rack, intermediate rack legs, etc.: They play the roles of supporting, dust-proofing and material guiding respectively in the conveyor.