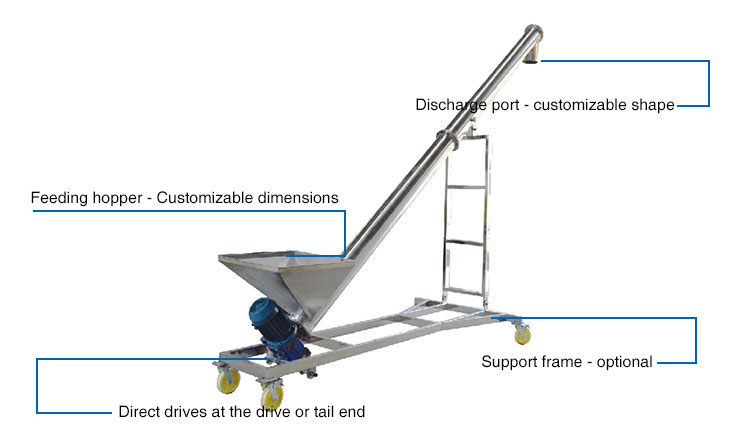

The structure and optional design of the inclined screw conveyor (movable, silo, liftable angle, etc.)

Tuesday February-07 2023 10:29:21

Similar to the structure of the conventional screw conveyor, the important structure of the inclined screw conveyor also includes the driving device (motor), deceleration device, screw, inlet and outlet, pipe groove, etc., because the inclined screw conveyor is placed obliquely, for the convenience of production and receiving Material, with its own bracket and silo structure.

The silo receives the material fed into the spiral tube, and the power generated by the motor drives the screw shaft to rotate. The propulsion generated by the spiral blade and the friction formed by the material, and the subsequent thrust into the conveying pipeline complete the material conveying work.

Drive device (motor) - conventional three-phase motor, lifting metallurgical motor, explosion-proof motor

The motor selection of the inclined screw conveyor includes the motor type, structure, capacity and speed, as well as the determination of the specific motor model. Three-phase AC asynchronous motors are used for conveying conventional materials (non-flammable, non-explosive, non-corrosive and other special requirements).

If your inclined screw conveyor needs to be used frequently in the scene of starting and reversing, and has high requirements on the moment of inertia and overload capacity of the motor, choose a YZ or YZR three-phase asynchronous motor for lifting and metallurgy.

If your material is special (inflammable and explosive), then in addition to choosing a sealed seamless conveying pipe groove, please choose an explosion-proof motor to ensure the safety of production and conveying.

Reduction device - cycloid reducer, shaft-mounted hardened gear reducer

The purpose of the deceleration device is to avoid the inability to feed or damage the machine due to the excessive speed of the inclined screw conveyor.

Scenarios when using an inclined screw conveyor

The gear hardness of the shaft-mounted hardened gear reducer can reach more than 350HBS, which is very suitable for heavy equipment such as screw conveyors. It can withstand the vibration and impact generated under high load and has a long service life.

Cycloidal pinwheel reducer is small in size, large in output torque, and high in transmission efficiency. It is suitable for the situation where the motor speed is relatively stable and the instantaneous torque does not exceed 2 times the rated torque.

Spiral form - with shaft, without shaft

The screw shaft of the inclined screw conveyor mainly has two forms: shafted and shaftless. If the inclination angle is below 30°, the shafted or shaftless screw can be selected arbitrarily. If the conveying angle exceeds 30°, shafted screw conveyor is selected.

Special design - brakeable universal wheels, built-in large silo, liftable design

Brakeable universal wheels: The conveying site of the inclined screw conveyor changes frequently, such as being used for docks; grain, sand and gravel; The movable wheels can be fixed to improve the safety of transportation.

Self-contained large silo: The basic feed silo can be specially designed and modified into a large silo, which can control the feed flow and provide certain material storage functions.

Liftable design: It is used for the situation that the actual conveying angle is many or the conveying angle is not fixed, and the height of the conveyor can be adjusted, but it is only suitable for the design and use of small and medium-sized inclined screw conveyors.

According to actual use requirements, the inclined screw conveyor can also be designed with different materials, special brackets or other details, and supports customization according to the site.