Truck Loading Conveyor

Thursday April-03 2025 13:40:43

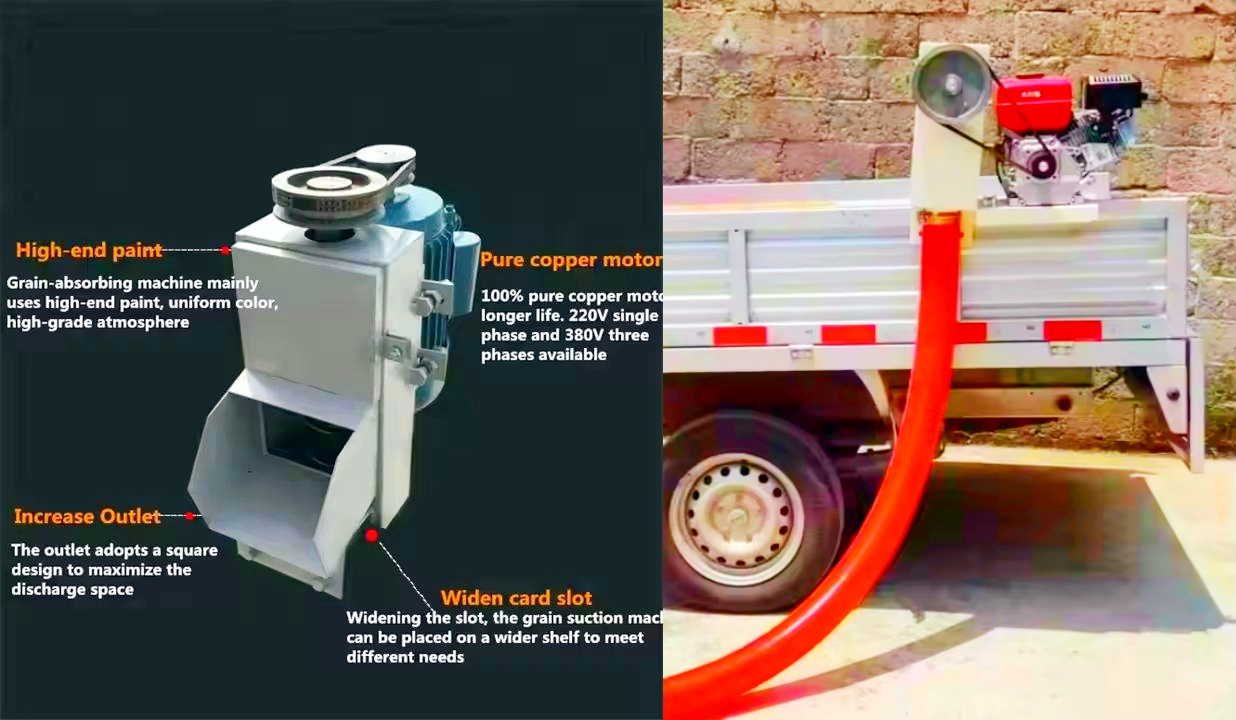

Truck loading conveyor is a kind of conveying equipment used to load bulk or bagged materials (such as sand, soil, grain, coal, etc.) onto trucks quickly and efficiently. It is widely used in logistics, ports, mines, construction sites, grain processing and other industries. It can improve loading efficiency and reduce manual operations. Truck loading conveyor generally consists of conveyor belt, support structure and power system. It can be fixed or mobile design, depending on the usage scenario.

Truck loading conveyor video

What is the working principle of truck loading conveyor?

① Material input: Material is placed at the starting point of the conveyor through the feed hopper of the truck loading conveyor or directly from other equipment.

② Conveyor belt movement: Truck loading conveyor is driven by an electric motor and drives the circulation through the roller.

③Material transportation: Materials are transported from the starting point to the end point.

④Loading to the truck: The end of the truck loading conveyor is usually located above the truck cargo box, and the materials fall naturally into the truck by gravity.

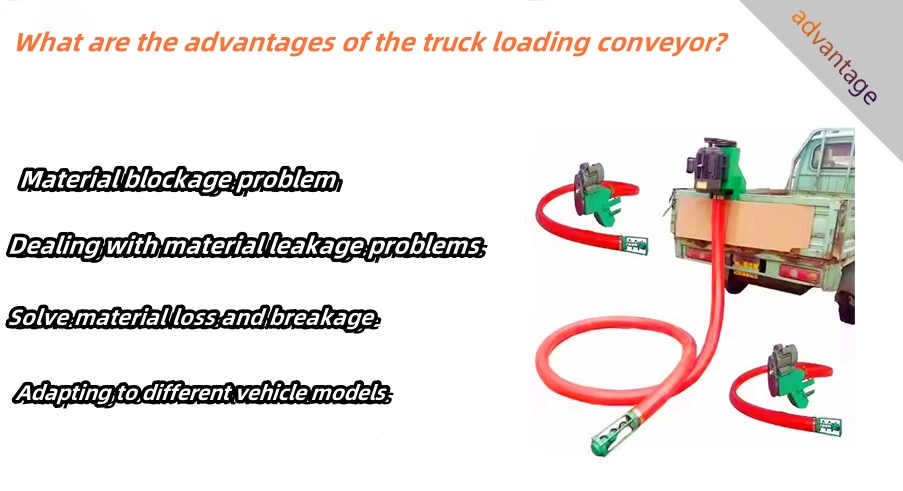

What are the advantages of the truck loading conveyor?

1. Material blockage problem

Certain materials with strong viscosity or easy to agglomerate (such as wet coal, clay) are easy to accumulate inside the conveyor belt or screw conveyor, causing blockage. Truck loading conveyor avoids the conveyor belt angle being too steep and reduces material backflow by reasonably designing the conveying angle.

2. Dealing with material leakage problems

Powdered or granular materials are easy to fall from both sides of the conveyor belt or the discharge port during high-speed transportation, causing waste and pollution. Truck loading conveyor is equipped with an adjustable gate or diversion device at the discharge port to control the discharge amount and reduce splashing.

3. Solve material loss and breakage

Fragile materials may be subjected to excessive impact during transportation, resulting in breakage or pulverization. Truck loading conveyor reduces the conveying speed and the breakage rate through frequency conversion control.

4. Adapting to different vehicle models

Different types of trucks have different heights and lengths, which may cause inconvenience in loading and unloading. The conveying length of truck loading conveyors is adjustable to adapt to different trucks.

Application of truck loading conveyors

When it comes to the application of truck loading conveyors, these devices play a key role in various scenarios.

Logistics centers, storage facilities and container terminals: Truck loading conveyors are used to quickly and efficiently transport goods from trucks to shelves or handling areas in warehouses. Truck loading conveyors are widely used in container loading and unloading operations. They can effectively move containers from trucks to yards or loading areas, speeding up cargo turnover.

Manufacturing assembly lines and construction sites: Truck loading conveyors are used to transport parts and raw materials from trucks to production lines. Truck loading conveyors can be used to transport construction materials such as bricks, concrete, steel, etc. from trucks to construction sites, reducing manpower handling and improving construction efficiency.

Mines, mining and agriculture: Truck loading conveyors are used to transport ore, coal, etc. from trucks to processing equipment or transportation equipment to achieve rapid loading and processing of ore. Truck loading conveyors can be used for loading and transporting agricultural products, such as transporting grain, feed, etc. from trucks to warehouses or processing equipment.

Truck loading conveyors play a very important role in many fields. They can significantly improve loading and unloading efficiency, reduce labor costs, and reduce damage to goods during handling.