Tumbling screen for sand

Monday March-31 2025 18:03:16

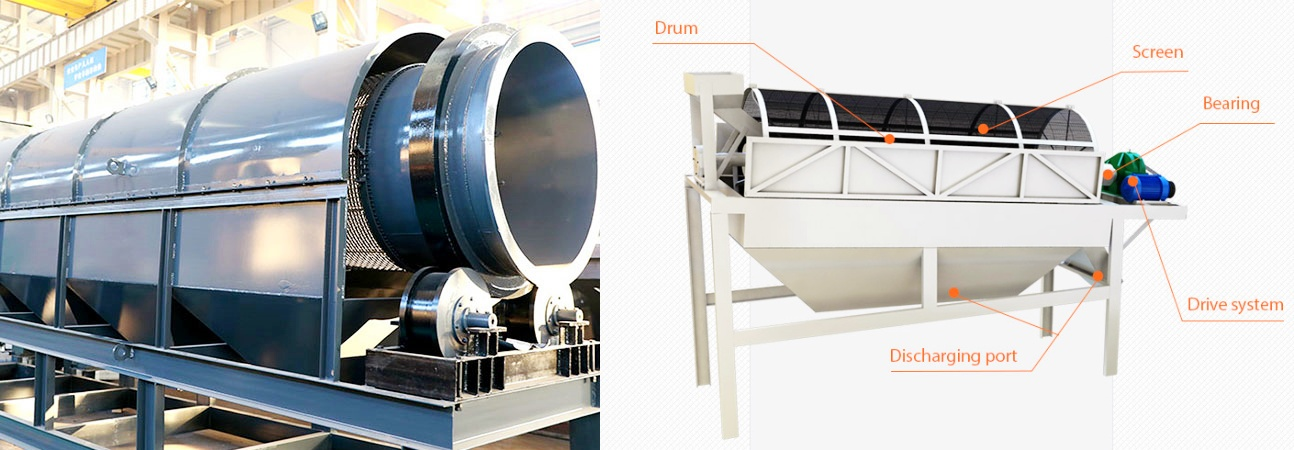

Tumbling screen for sand is a drum-type vibrating screening equipment commonly used for granular materials such as sand, ore, coal, and construction waste. Tumbling screen for sand rolls and screens the sand in the screen through the rotating motion of the drum to achieve the separation effect of different particle sizes. It is widely used in sand and gravel fields, building materials, mining, chemical industry and other fields, mainly used for grading, impurity removal or separation of sand to meet different particle size requirements.

Video of tumbling screen for sand

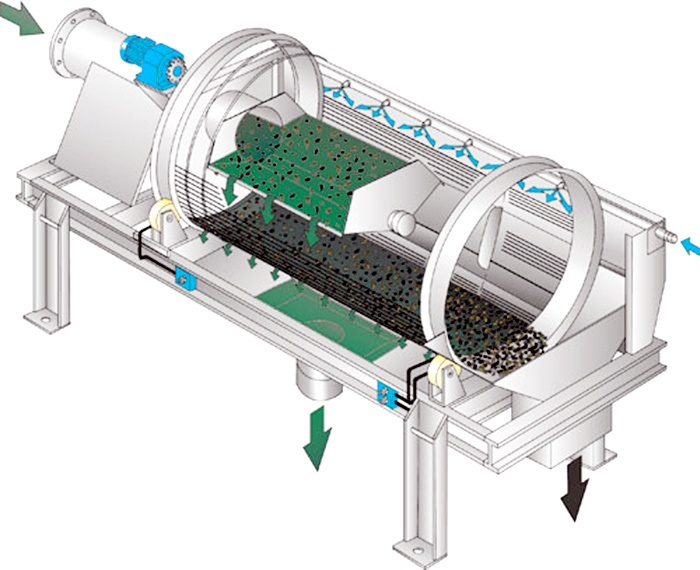

How does the tumbling screen for sand work?

Sand enters the inclined rotating cylindrical screen from the feed inlet, and the inner wall of the cylinder is equipped with screens of different mesh sizes. As the drum rotates, the sand rolls and slides in the drum. Fine sand smaller than the mesh size falls through the mesh into the collection device, while coarse sand larger than the mesh size is discharged at the end of the drum.

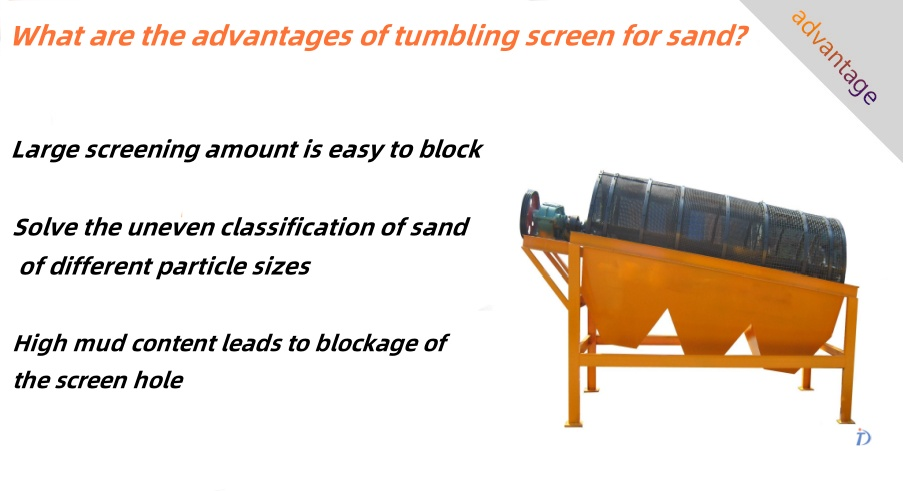

What are the advantages of tumbling screen for sand?

1. Large screening amount is easy to block: The feed port of the drum screen can be equipped with a uniform distribution device to ensure that the material enters the screen evenly and improve the screening effect. Tumbling screen for sand is used with a conveyor or a vibrating feeder to control the feed speed and avoid blockage.

2. Solve the uneven classification of sand of different particle sizes: Tumbling screen for sand adopts a multi-stage screen structure, which can simultaneously screen out sand of different particle sizes to meet various application requirements (such as construction sand, concrete sand, quartz sand, etc.).

3. High mud content leads to blockage of the screen hole: Sand often contains mud and stone powder, which is easy to stick together when wet and block the screen hole. Tumbling screen for sand uses a large-aperture woven mesh (such as 3-5mm) to reduce the probability of fine particles getting stuck.

Recommended mesh number of tumbling screen for sand

Coarse screen: 5-20 mesh (aperture 1-4mm), remove large particles of impurities.

Medium screen: 20-40 mesh (aperture 0.425-0.85mm), suitable for standard construction sand.

Fine screen: 50-100 mesh (aperture 0.15-0.3mm), produce high-precision fine sand, such as sand for plaster mortar.

Recommended screen specifications for tumbling screen for sand

|

Sand type |

Screening target |

Recommended sieve size |

Corresponding mesh number |

Application scenario |

|

Construction sand |

Coarse aggregate separation |

5-10mm |

3-8 mesh |

Concrete ingredients |

|

Construction sand |

Medium sand extraction |

2.5-5mm |

8-20 mesh |

Masonry mortar |

|

Construction sand |

Fine sand classification |

0.6-2.5mm |

20-40 mesh |

Plastering mortar |

|

Quartz sand |

Glass raw material purification |

0.3-0.6mm |

40 -60 mesh |

Photovoltaic glass sand |

|

Quartz sand |

Precision casting sand |

0.1-0.3mm |

60-100 mesh |

3D printing sand mold |

|

Sea sand desalination |

Shell/coral debris removal |

2-4mm |

10-15 mesh |

Construction sand pretreatment |

Application of tumbling screen for sand

Construction sand processing: The construction industry has a wide demand for sand of different particle sizes. Tumbling screen for sand needs to grade natural sand or machine-made sand according to specifications and screen out impurities such as grass roots, shells, and mud blocks mixed in the sand.

Mining tailings resource utilization: The tailings sand produced by mining contains a large amount of fine particles and needs to be screened and recycled. The sand drum screen extracts fine sand from the tailings through a small-aperture screen for brick making or filling.

River dredging and sand mining: The silt sand produced by river dredging contains a large amount of water and impurities. Tumbling screen for sand intercepts the sand particles, and the mud is discharged through the screen holes to achieve solid-liquid separation (the water content can be reduced to below 20%).

Preparation of agricultural seedling matrix: The seedling matrix needs to be a light, breathable sand material, and large particles and impurities need to be screened out. Tumbling screen for sand uses a 3-5mm screen to separate sand particles of uniform particle size.

Industrial raw material pretreatment: Chemical, ceramic and other industries need to control the particle size of raw materials such as quartz sand and corundum. Tumbling screen for sand controls the drum speed through frequency conversion speed regulation to achieve accurate screening of sand particle size.

Tumbling screen for sand is an efficient and durable screening equipment, widely used in construction, mining, environmental protection and other industries. It can effectively screen and grade sand, improve product quality, reduce impurity content, and improve overall production efficiency. If you have specific production needs (such as output, screening accuracy, etc.), you can contact our customer service to help you recommend a more suitable equipment configuration!