Types of Chain Type Bucket Elevator

Tuesday March-15 2022 10:27:14

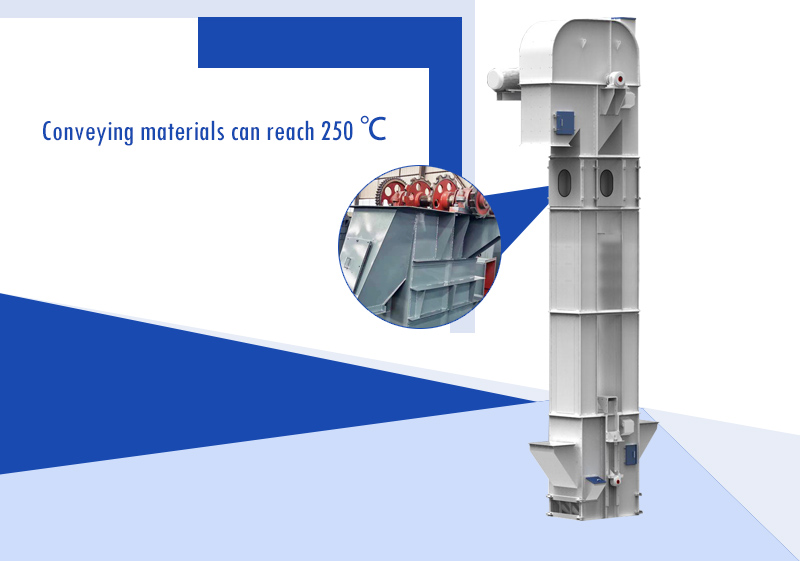

ONE: Chain Bucket Elevator

Bucket elevators with ring chain structure are relatively simple to manufacture. They use circular ring chains as traction components, and the connection between the hoppers is relatively firm. , chemical fertilizer, etc., the temperature of conveying materials can reach 250 ℃.

The outstanding advantages of the chain bucket elevator:

1. The conveying capacity is large. Compared with the HL type with the same bucket width, the conveying capacity is nearly doubled.

2. The improved conveying capacity of the improved model is more than 30% higher than that of the ordinary model. The lifting height can reach 40 meters.

3. The traction part is a high-strength circular chain made of low-alloy steel. After reasonable heat treatment, it has high tensile strength, good wear resistance and long service life.

4. The assembled sprocket is adopted. The wheel body and the rim are connected by high-strength bolts. After the sprocket is worn to a certain extent, the bolts can be unscrewed and the rim can be removed and replaced, which is convenient for replacement, saves materials and reduces maintenance costs.

5. The lower part adopts a heavy hammer lever type tensioning device, which can realize automatic tensioning. No adjustment is required after a single installation, and a constant tension can be maintained, thereby ensuring the normal operation of the machine and avoiding slippage or off-chain.

6. The transmission device is equipped with a backstop, which can effectively prevent the occurrence of "feedback".

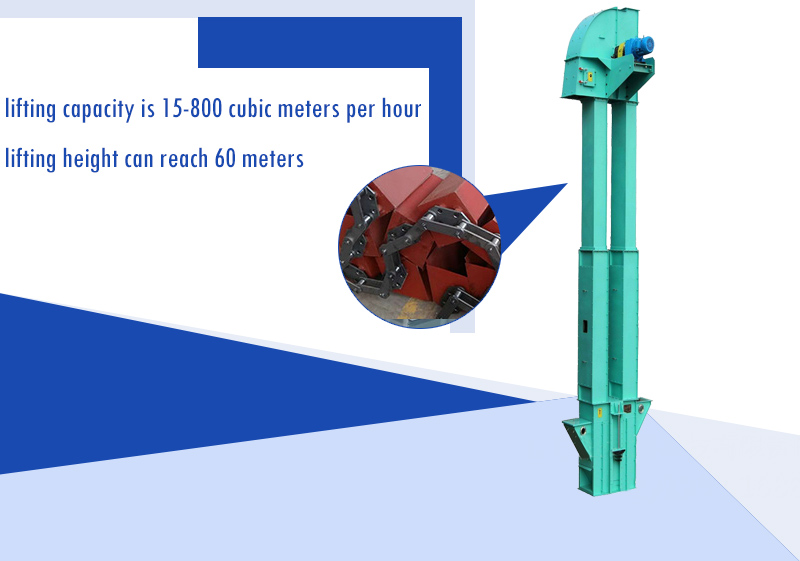

TWO: Plate Chain Bucket Elevator

The plate chain bucket elevator is divided into single chain bucket elevator and double chain bucket elevator.

The plate chain bucket elevator is light in weight and firm in structure. It is suitable for lifting materials with a large amount. It adopts a fully enclosed casing with low chain speed and almost no material return phenomenon. The temperature of the conveyed material can reach 250 °C.

The outstanding advantages of plate chain bucket elevator:

1. The plate chain bucket elevator adopts plate chain drive to reduce manual operation and increase work efficiency. The lifting capacity is 15-800 cubic meters per hour, and the lifting height can reach 60 meters.

2. There are few requirements for the types and characteristics of materials, not only can improve the general powder, small granular materials, but also can improve the grinding materials, the required temperature ≤ 200 ° C.

3. Adopt inflow feeding, inductive unloading and dense arrangement of large-capacity hoppers. There is almost no material returning and digging during material lifting, so the ineffective power is less, and the power is saved by 30% compared with the chain hoist.

4. Good structural rigidity and high precision. The casing is folded and embossed in the middle. After welding, it has good rigidity and beautiful appearance. The surface of the product is painted, and the surface is smooth and not easy to fall off.

Both chain bucket elevators can be made of carbon steel and stainless steel according to the different materials to be lifted.